What is Aseptic Filling?

Definition, Differences & Benefits

Aseptic filling: preserving freshness, extending reach

Aseptic filling combines state-of-the-art sterilization of both product and packaging with a fully controlled filling environment—guaranteeing that every bottle, carton, or pouch leaves the line at peak quality. By eliminating post-fill heat treatment, this method locks in natural flavor, aroma, and nutrients while enabling ambient-stable storage, reduced logistics costs, and entry into new markets without refrigeration.

|

|

|

|

What is aseptic filling?

Aseptic filling is the process of filling pre-sterilized containers with sterilized products in a sterilized environment, thereby ensuring that neither the product nor the packaging becomes contaminated during the filling stage. Unlike in-container (terminal) sterilization—where product and container are filled first and then heat-treated together—aseptic filling separates the sterilization of product and container, then combines them under strict sterile conditions.

|

|

Aseptic filling process overview

Aseptic filling is executed through a series of highly controlled steps designed to maintain sterility from product preparation to final sealing. The overall workflow typically consists of the following stages:

1. Product sterilization

The liquid product is sterilized using methods such as Ultra High Temperature (UHT) processing or filtration. This step ensures that microorganisms are eliminated before filling.

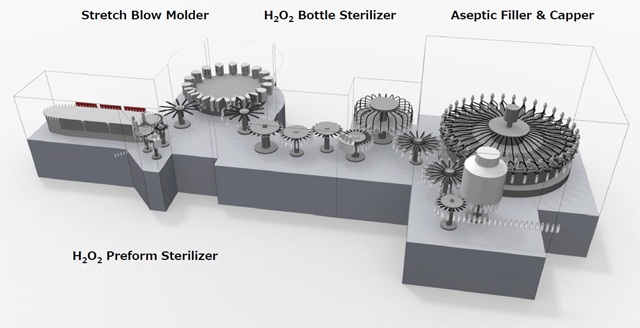

2. Container and closure sterilization

Bottles, caps, or other containers are sterilized separately using heat, chemical sterilants (e.g., hydrogen peroxide), or radiation. Each component must achieve the required level of sterility before entering the aseptic zone.

3. Aseptic environment preparation

A controlled environment—maintained with HEPA-filtered air, positive pressure, and continuous monitoring—is established to prevent contamination during filling. Airflow control and cleanroom technology play critical roles here.

4. Filling and sealing

The sterilized product is filled into the sterilized container inside the aseptic zone, and immediately sealed. This is the core technology of aseptic filling systems.

5. Monitoring and verification

Monitoring Critical Control Points (CCPs), along with sterilization validation and container integrity checks, ensures that aseptic conditions are maintained throughout the process. These steps help guarantee product safety and quality.

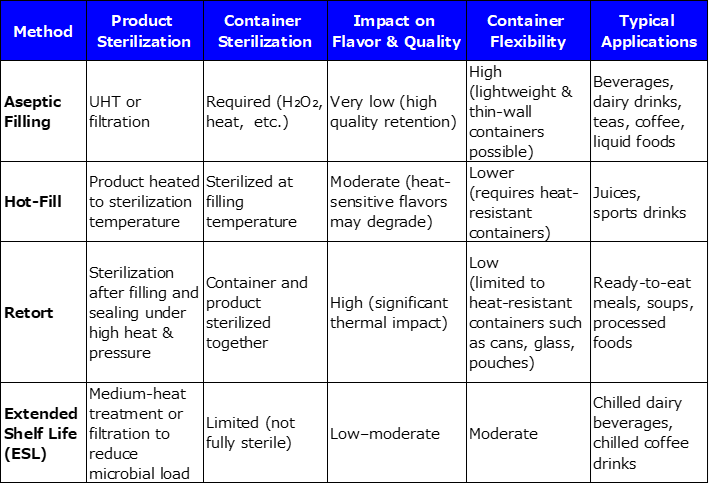

Comparison: other methods vs. aseptic filling

|

|

Aseptic filling

Aseptic filling is a process in which a sterilized product is filled into a separately sterilized container within a controlled aseptic environment. The liquid product is typically sterilized using UHT (Ultra High Temperature) processing or filtration, while containers are sterilized through methods such as hydrogen peroxide, heat, or UV treatment. Because the product and container are brought together in a sterile zone, flavor, aroma, and nutritional quality are well preserved. The method also enables the use of lightweight and thin-wall packaging, making it widely adopted for beverages, dairy drinks, and liquid foods.

Hot-fill

Hot-fill is a method in which a heated, sterilized product is filled into the container while still at high temperature, allowing the product itself to sterilize the inner surface of the container. This eliminates the need for a dedicated container sterilization step, resulting in relatively simple system configuration and lower initial investment. However, the high heat can alter flavor and aroma, particularly in heat-sensitive products, and requires the use of heat-resistant containers. Hot-fill is commonly used for juices, sports drinks, and tea-based beverages.

Retort

Retort processing involves filling and sealing the product in its container, followed by sterilization of the entire package using high temperature and pressure in a retort chamber. This provides excellent sterilization certainty, making it suitable for a wide range of shelf-stable foods. However, the intense thermal treatment can significantly change flavor, texture, and nutritional properties. The method also requires robust, heat-resistant containers, such as metal cans, glass bottles, and retort pouches. Retort is widely applied in ready-to-eat meals, soups, sauces, and various processed foods.

Extended Shelf Life (ESL)

Extended Shelf Life (ESL) technology reduces the microbial load of a product through medium-heat treatment or filtration, followed by filling in a hygienic—though not fully sterile—environment. ESL does not achieve the same level of sterility as aseptic filling, so refrigerated distribution is required. Nevertheless, it maintains flavor and nutritional quality better than hot-fill, making it suitable for chilled beverages such as dairy drinks and chilled coffee products.

Advantages of the aseptic filling method

1. Superior product quality

Short, high-temperature sterilization of the product followed by ambient-temperature filling avoids spoiling the flavor, color, and heat-labile nutrients, resulting in a sensory profile much closer to “fresh.”

2. Ambient-stable shelf life & efficient logistics

Aseptically filled, commercially sterile packages stay safe for several months at ambient temperature. This eliminates the need for refrigerated transport or storage, significantly reducing distribution costs and enabling access to markets where cold-chain infrastructure is limited or prohibitively expensive.

3. Packaging flexibility

Because the filled package in aseptic filling never reaches retort temperatures, lightweight PET, laminated cartons, and pouches can replace heavier glass or metal. This reduces material use while broadening design options.

Our aseptic filling technologies

|

|

Our aseptic filling technologies embody the spirit of continuous improvement—“KAIZEN”—to deliver optimal performance across every dimension: high productivity, high quality, lower total cost of ownership (TCO), and sustainability.

By integrating advanced sterilization methods with precisely controlled aseptic environments, our systems ensure safe, premium liquid products with excellent flavor and nutritional retention. Optimized container sterilization, efficient aseptic zones, and accurate filling and sealing mechanisms enable stable, high-speed production while minimizing downtime and resource use. Furthermore, our solutions support lightweight, eco-friendly packaging, helping customers enhance operational efficiency and environmental responsibility simultaneously.

Aseptic filling solutions, please visit our solution page here: