Green Aseptic™ Tea Filling in PET Bottles for CO₂ Reduction and Energy Savings

Tea Filling Machine Case Study — 36,000 bph PET Bottle Line at Shizuoka Soft-Drink Plant (Japan)

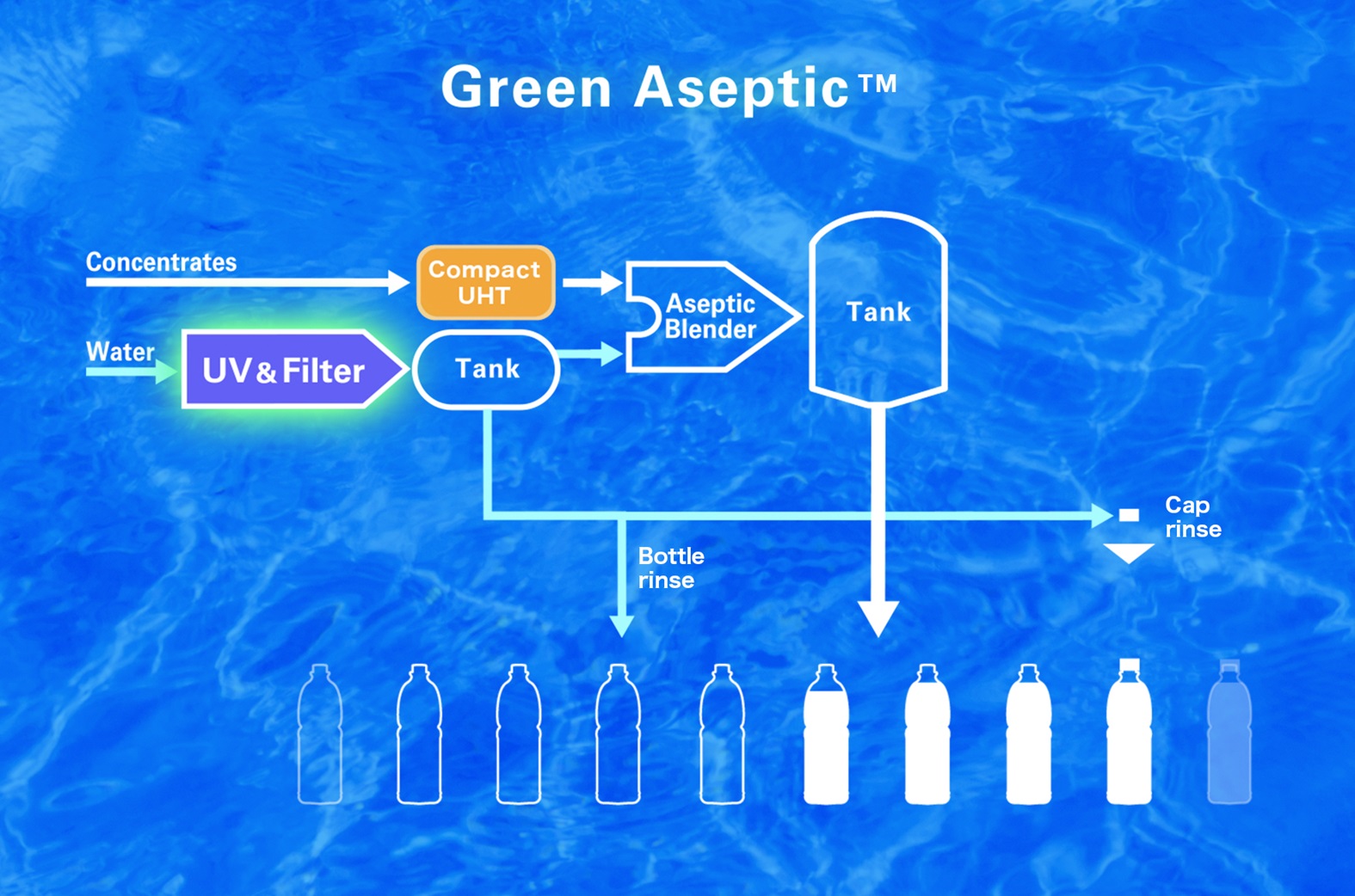

Water is the main ingredient in soft drinks. To achieve decarbonization in the soft drink production process, DNP has developed Green Aseptic, a next-generation system for non-thermal water sterilization.

In April 2024, a major soft-drink plant in Shizuoka began commercial tea production using DNP’s Green Aseptic system. To accommodate growing demand, a new facility for beverage production and warehousing was completed in March 2024.

Table of contents

|

|

Project overview of the tea filling machine installation

Location: Shizuoka Prefecture, Japan (new factory opened in March 2024)

Start-up: April 2024

Products: Green tea, oolong tea, etc.

Line speed: 36,000 bph (500ml PET)

Aseptic validation: 3× media-fill runs, over 10,000 bottles each resulting in 0 spoilage

Technology scope: Green aseptic non-thermal water sterilization, compact UHT sterilizer for the product concentrate, and aseptic blender

How Green Aseptic powers the tea filling machine

|

|

With DNP's system, the product concentrate is heat-sterilized using a compact UHT sterilizer and then diluted with non-thermal sterile water. After being mixed in an aseptic blender, the product is filled with an aseptic filler. Compared to the conventional method of sterilizing product liquids using UHT sterilizers alone, this new aseptic processing achieves approximately 80% decarbonization and energy savings according to our research and data monitoring.

Tea filling machine process powered by Green Aseptic

1. Tea extraction & UHT sterilization

|

|

To make the tea for the tea filling machine, carefully selected tea leaves from Japan are steeped in hot water within an extractor to maximize their flavor and richness. They are then sterilized in a compact UHT sterilizer and sent to an aseptic tank. High-temperature, short-time sterilization in the UHT sterilizer preserves the original flavor and color of the teas.

2. Non-heat sterile water production

Water for the tea filling machine is pumped up from approximately 180 meters below ground and, after removing foreign matter, is sterilized using powerful UV lamps and sterilization filters. DNP focused on Atlantium’s Hydro-Optic™ (HOD) system, which uses medium-pressure UV lamps that have proven their worth as disinfection devices for raw water in beverage production. After repeated sterilization tests conducted at DNP’s research laboratory, the lamps were modified to specifications for use in aseptic zones.

The sterilization filters undergo automatic "integrity testing," where pore sizes are checked before and after production to ensure sterility is maintained under precise aseptic conditions. To further extend the life of the 0.1 µm sterilization filters, DNP’s F₀ solution has been installed, performing the SIP process on these filters, minimizing the effects of thermal damage to the filters.

By combining these particular Atlantium medium-pressure UV lamps and customized 0.1 µm sterilization filters, DNP produces non-heat sterile water that feeds directly into the tea filling machine.

|

|

3. Aseptic blending & PET bottle filling

UHT-sterilized tea extract is aseptically blended with ultra-low carbon sterile water at a high dilution ratio. Then 500ml PET bottles are aseptically filled at 36,000 bph using an aseptic filler. All conventional heat-sterilized sterile water used for rinsing bottles, closures, and chambers in the aseptic filling machine has been replaced with non-heated, sterile water.

Aseptic verification of the tea filling machine

Aseptic verification was conducted on the tea filling machine to determine whether the Green Aseptic system was as sterile as a conventional UHT sterilizer. This verification was conducted on site by Aseptic Systems Co., Ltd. (APS), DNP’s aseptic technology department. The method was to first heat sterilize a highly concentrated pH 7 media broth in the compact UHT sterilizer.

Sterile water was produced by non-heat sterilization using medium-pressure UV lamps and sterilization filters. These were mixed in the aseptic blender and aseptically filled by the filler. More than 10,000 media-filled bottles were incubated per test.

After one week of incubation at 30°C, all bottles were visually inspected to ensure there were no spoiled bottles. This media fill test was carried out three times, and afterwards, all tests confirmed zero spoilage. These test results validated the reliability of Green Aseptic and allowed production to start, as planned, on April 1, 2024.

|

|

Creating future standards for tea filling machines

The history of aseptic packaging began in the 1960s. The technology fills heat-sterilized products into sterilized packs in an aseptic environment. Products that cannot be heat sterilized are filtered and sterilized using a 0.2 µm sterilization filter. However, 0.2 µm sterilization filters have been reported to allow ultra-small and filterable bacteria to pass through.

DNP tested the UV resistance of these bacteria and found UV irradiation conditions that kill UV-resistant filterable bacteria at 12 Log or more. By combining medium-pressure UV lamps with 0.1 µm sterilization filters, DNP successfully produced sterile water with the same level of sterility as conventional heat sterilization without heating. This patented technology has enabled significant decarbonization and energy savings in liquid processing equipment for low and high-acid beverages. DNP is committed to using its long-established aseptic technology to solve today’s societal challenges and contribute to the realization of a sustainable society.

Other case studies

-

Versatile Aseptic PET Filler for Juice and Soda with Fastest Changeovers

Juice Filling Machine Case Study — 54,000 bph PET ...

- Packaging

In April 2021, DNP’s aseptic PET bottle juice filling machine began operation at the Nagoya factory ...

-

Trusted Aseptic PET Systems by China’s Top Water Brand

Water Filling Machine Case Study — Nongfu Spring I...

- Packaging

As of 2022, DNP has received orders for more than 20 aseptic filling systems for PET bottles over th...

-

The High Pressure Sterilized Draft Sake Consortium

DNP Developed Complex PET Bottle Adopted as Japane...

- Packaging

We developed an integrally preform-based stretch blow molded plastic bottle with a colored film that...

-

Shirataki Sake Brewery

Functional Colored Film-Covered Recyclable Plastic...

- Packaging

We developed an integrally preform-based stretch blow molded plastic bottle with a colored film that...

.png)