Versatile Aseptic PET Filler for Juice and Soda with Fastest Changeovers

Juice Filling Machine Case Study — 54,000 bph PET Bottle Line at Asahi Nagoya (Japan)

In April 2021, DNP’s aseptic PET bottle juice filling machine began operation at the Nagoya factory of Asahi Breweries. Our machine offers three key features:

・It can fill both carbonated and non-carbonated beverages.

・The changeover time for the aseptic system is less than two hours.

・It operates at a speed of 54,000 bph (bottles per hour).

In summary, this system is a highly productive filling solution for a wide variety of beverages, maintaining Japan’s high standards of aseptic quality and contributing to a reduction in environmental impact.

Table of contents

|

|

Project overview of the juice filling machine installation

Location: Aichi Prefecture, Japan – Asahi Nagoya Plant (existing facility)

Start-up: April 2021

Products: Mitsuya Cider, Wilkinson, Calpis (Calpico), Calpis Soda

Line Speed: 54,000 bottles/hour (≤ 500ml PET), 20,000 bottles/hour (1.5L PET)

Aseptic Validation:

Commissioning: 3× media-fill tests, over 30,000 bottles → 0 spoilage

Annual overhaul: ≥ 10,000 bottles → 0 spoilage

Technology Highlights:

Aseptic PET system for carbonated and still beverages

In-line energy-saving blow molder

H₂O₂ gas sterilization with 40% reduction in H₂O₂ usage

CSIP (simultaneous CIP & SIP) enables changeover in under 2 hours

Chamber sterilization mode for high-acid beverages

Pasteurizer-free aseptic filling for high-CO₂ carbonated drinks

High-speed PET bottle juice filling machine for three Asahi brands

|

|

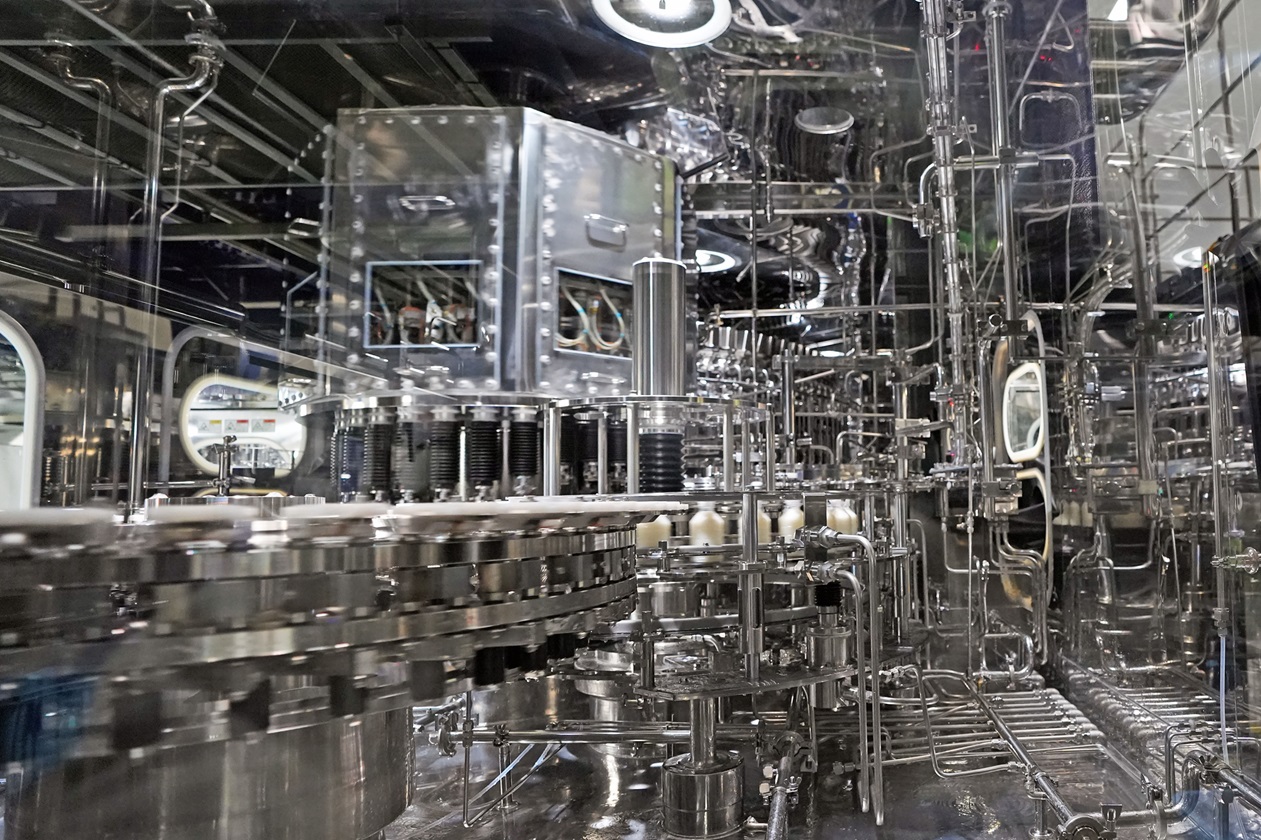

Asahi Soft Drinks has three major brands with a history of over 100 years: the carbonated drinks ‘Mitsuya Cider’ and ‘Wilkinson’, and the lactic beverage ‘Calpis (Calpico)’. The production volumes of these brands have grown steadily, leading to the establishment of a new production line in Aichi Prefecture, in the center of Japan. To support these three major Asahi brands, DNP deployed an aseptic PET bottle juice filling machine capable of producing both carbonated and non-carbonated beverages.

Additionally, to maximize productivity, the flow rate of the UHT sterilizer was designed to be 30m³/h, achieving a high-productivity line of 54,000 bph for small PET bottles (500ml or less), and 20,000 bph for 1.5-liter PET bottles.

This system consists of an energy-saving blow molder directly connected to an aseptic filler.

The benefit is not only a smaller footprint, but also secure and reliable bottle sterilization using H₂O₂ gas.

The bottle temperature after blow molding is approximately 50 °C, which significantly enhances the effectiveness of H₂O₂ gas decontamination. As a result, the amount of H₂O₂ used for sterilization is reduced by around 40% compared to conventional systems.

All bottles are conveyed from the blow molder to the aseptic filler by gripping the neck ring, allowing high operation rates to be maintained even with frequent changes in bottle types.

During commissioning, operation rate verification tests were conducted using five different bottle types over more than eight hours of production. All tests achieved a high operation rate of over 95%.

|

|

Advanced technologies driving productivity and sustainability

CSIP: 2-hour changeover keeps the juice filling machine running

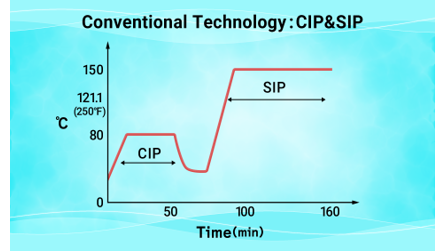

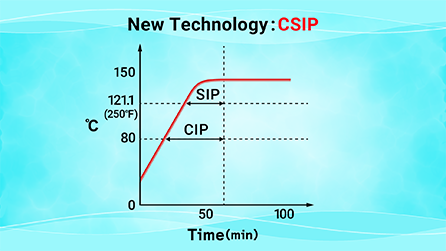

Generally, in the case of aseptic filling systems, production of a large number of varieties reduces productivity. This is because the Sterilization-In-Place (SIP) process is required after the Cleaning-In-Place (CIP) process. DNP has developed an advanced aseptic processing technology that enables simultaneous SIP (Sterilization-In-Place) and CIP (Cleaning-In-Place) operations. This innovation allows manufacturers to skip SIP after CIP, significantly reducing downtime and improving production efficiency in beverage filling systems. This patented technology that performs CIP and SIP simultaneously is called “CSIP".

At the Asahi Nagoya factory, CSIP was installed across the UHT sterilizer, aseptic tanks and the juice filling machine. As a result, these systems were cleaned and sterilized within two hours, resulting in a significant reduction in production intervals. Needless to say, shorter changeover times, high operation rates and high-speed machines directly lead to lower TCO.

|

|

Conventional Aseptic Sanitation: Separate CIP & SIP

|

|

CSIP Process: Combined CIP & SIP

Aseptic CSD: Pasteurizer-free PET bottle juice filling machine for high-CO₂ drinks

|

|

The Calpis brand of lactic beverages has a long-standing popular product called ‘Calpis (Calpico) Soda’ since 1973. Carbonated beverages requiring sterilization, such as Calpis Soda, have previously had to be filled at low temperature and then the product sterilized in a pasteurizer at 65 °C or higher for at least 10 minutes to comply with the Japanese Food Sanitation Law. The higher the temperature of the carbonated beverage, the greater the pressure inside the PET bottle, making it difficult to ensure proper cap sealing. Therefore, it was necessary to use special pressure- and heat-resistant PET bottles with crystallized mouth parts.

In 2008, DNP introduced Aseptic CSD, an innovative pasteurizer-free PET bottle filling system designed for high-carbonation (high-CO₂) beverages in lightweight PET bottles. By integrating an aseptic carbonation filler, Aseptic CSD enables the filling of carbonated liquids into standard PET bottles without downstream pasteurization, eliminating the need for specialized bottles and heat treatment. Removing the pasteurizer not only reduces the production line footprint, but also significantly lowers steam and water consumption, contributing to energy efficiency and sustainability.

Additionally, the use of lighter PET bottles and the elimination of heat-based sterilization help reduce CO₂ emissions, making the system an environmentally friendly solution for beverage manufacturers.

A further advantage of Aseptic CSD is its ability to safely handle high-gas-volume products, thanks to the removal of the tunnel pasteurizer — giving manufacturers greater flexibility in product design and expanding possibilities for carbonated beverage innovation.

High-acidity mode: optimizing the PET bottle juice filling machine for Calpis

In 2008, DNP installed the first aseptic filling system for Calpis at Asahi’s Gunma factory.

At the time, most aseptic filling systems in Japan were designed for low-acid beverages such as tea and milk-based drinks. These systems were over-specified for high-acid beverages like Calpis, resulting in unnecessary complexity and inefficiency.

To address this, DNP developed a specialized PET bottle juice filling machine called High Acidity Aseptic, optimized for high-acid beverage production. This system successfully reduced Sterilization-In-Place (SIP) time by one-sixth compared to conventional low-acid aseptic systems.

Today, DNP’s aseptic filling technology has evolved into smart systems that can automatically switch sterilization modes between high-acid and low-acid beverages.

This automatic switching capability is based on DNP’s patented technology, offering beverage manufacturers enhanced operational flexibility, energy efficiency, and sustainability.

Aseptic validation: 30,000-bottle media-fill on the juice filling machine

Since 1994, DNP has been conducting sterility verification during commissioning of aseptic filling machines through media-fill tests, a method now expanding across China and Southeast Asia.

In media-fill tests, adding CO₂ to the test media lowers the pH and inhibits bacterial growth, which can compromise the accuracy of sterility verification. To address this, the Asahi Nagoya factory switched from CO₂ to sterile air, ensuring reliable test conditions.

During commissioning, over 30,000 PET bottles were filled and incubated at 30 °C for one week. The result: zero spoilage, confirming sterility and allowing production to begin as scheduled.

In Japan, DNP continues to uphold strict standards by conducting annual media-fill tests of more than 10,000 units after each aseptic system overhaul, ensuring that sterile conditions are fully maintained before restarting production.

This rigorous verification process reflects DNP’s commitment to food safety, quality assurance, and long-term reliability — helping our customers deliver safe and secure beverages to consumers.

Future standards in PET-bottle beverages and liquid filling

DNP began developing aseptic filling machines for UHT-sterilized coffee creamer in 1972.

Since then, our aseptic filling technology has continuously evolved to meet the changing needs of customers and society. This evolution has led to the launch of aseptic systems for a wide range of packaging formats, including Bag-in-Box, cups, paper cartons, pouches, and PET bottles.

DNP will continue to research and develop advanced aseptic technologies to address the evolving social and environmental challenges of each era, contributing to the realization of a safe, secure, and sustainable society.

|

|

Other case studies

-

Green Aseptic™ Tea Filling in PET Bottles for CO₂ Reduction and Energy Savings

Tea Filling Machine Case Study — 36,000 bph PET Bo...

- Packaging

Water is the main ingredient in soft drinks. To achieve decarbonization in the soft drink production...

-

Trusted Aseptic PET Systems by China’s Top Water Brand

Water Filling Machine Case Study — Nongfu Spring I...

- Packaging

As of 2022, DNP has received orders for more than 20 aseptic filling systems for PET bottles over th...

-

The High Pressure Sterilized Draft Sake Consortium

DNP Developed Complex PET Bottle Adopted as Japane...

- Packaging

We developed an integrally preform-based stretch blow molded plastic bottle with a colored film that...

-

Shirataki Sake Brewery

Functional Colored Film-Covered Recyclable Plastic...

- Packaging

We developed an integrally preform-based stretch blow molded plastic bottle with a colored film that...