Aseptic Filling Process Enabled by Two-Step Sterilization

DNP has introduced a next-generation aseptic filling system for PET bottles, featuring a proprietary Two-Step Sterilization process that integrates both preform and bottle decontamination. This innovation has significantly reduced the system footprint and total cost of ownership (TCO). Recognized as one of the most sterile and reliable aseptic filling technologies globally, the Two-Step Sterilization system sets a new benchmark in beverage safety and efficiency.

Table of contents

Video:Two-step sterilization system(1:48)

Problems with conventional aseptic filling systems

Conventional aseptic PET filling lines rely on large-scale bottle sterilizers, extended water-rinsing tunnels, and multiple H₂O₂ evaporators—resulting in oversized footprints, excessive chemical and water consumption, and high energy costs.

What is the new aseptic filling system "two-step sterilization"?

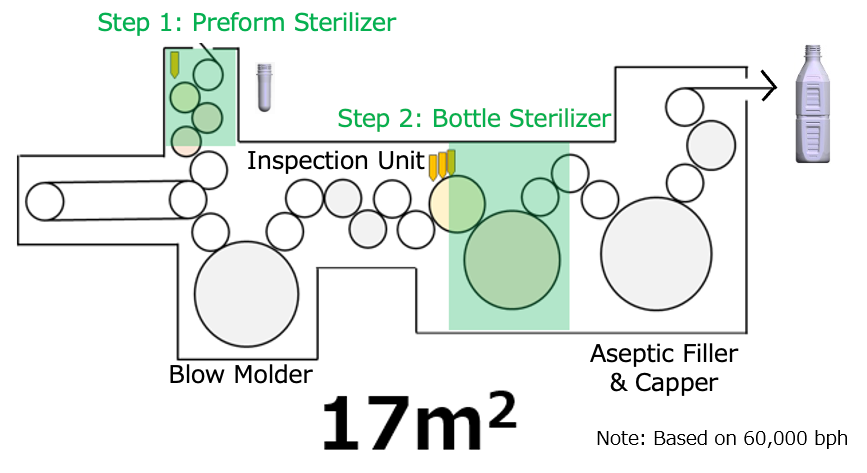

The new aseptic filling system for PET bottles features a two-step sterilization process. The first sterilization takes place at the preform stage, before blow molding, and the second occurs after blow molding, once the bottle has been formed.

STEP 1: Preform sterilization

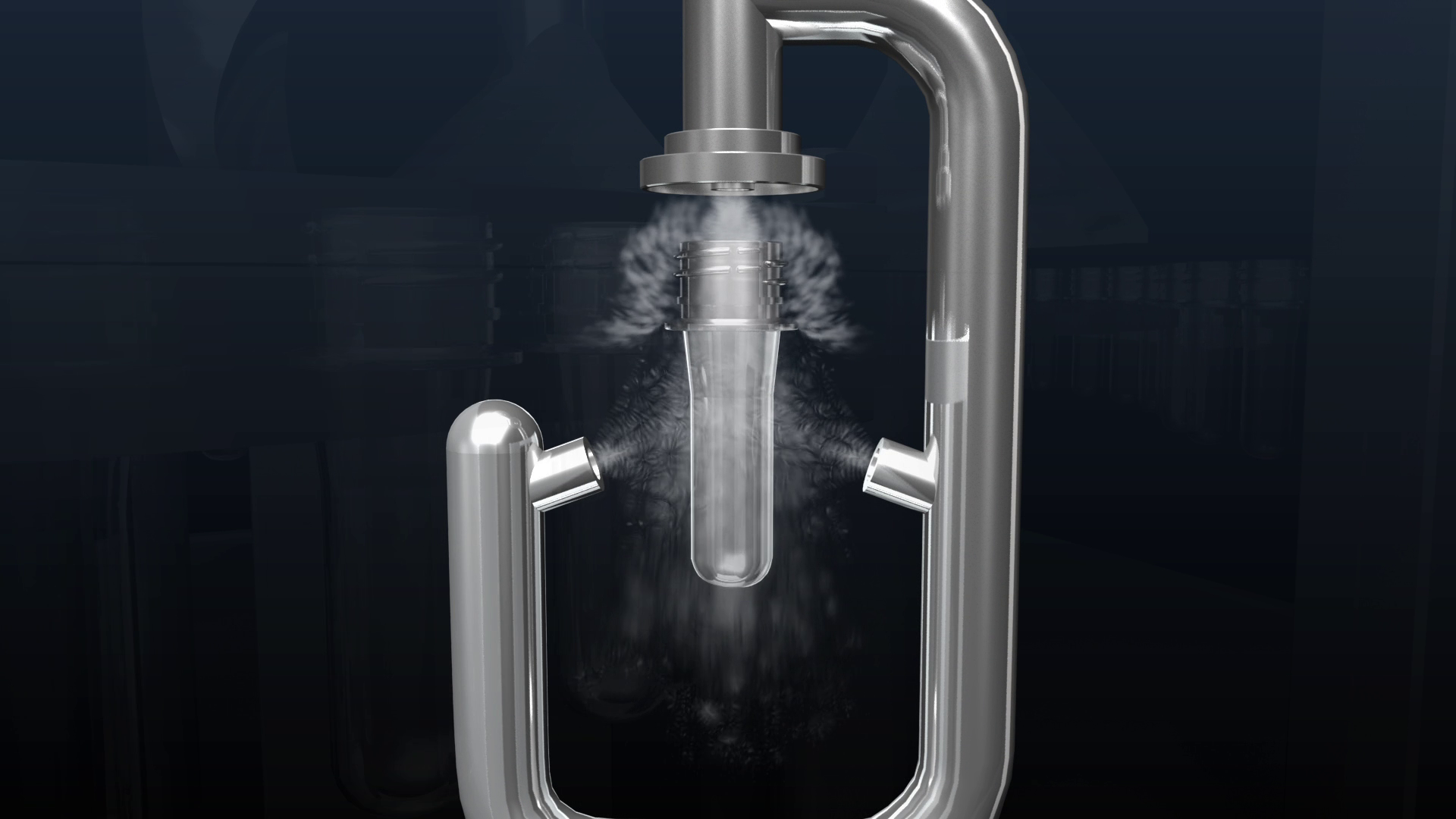

Sterilization is performed by a compact unit located at the entry point of the blowing machine, consisting of two rotating wheels. On the first wheel, both the inner and outer surfaces of the preforms are simultaneously sprayed with a hydrogen peroxide mist. On the second wheel, sterile hot air is applied to remove residual hydrogen peroxide. The preforms are then heated to between around 100°C to 120°C to enhance the sterilization effect.

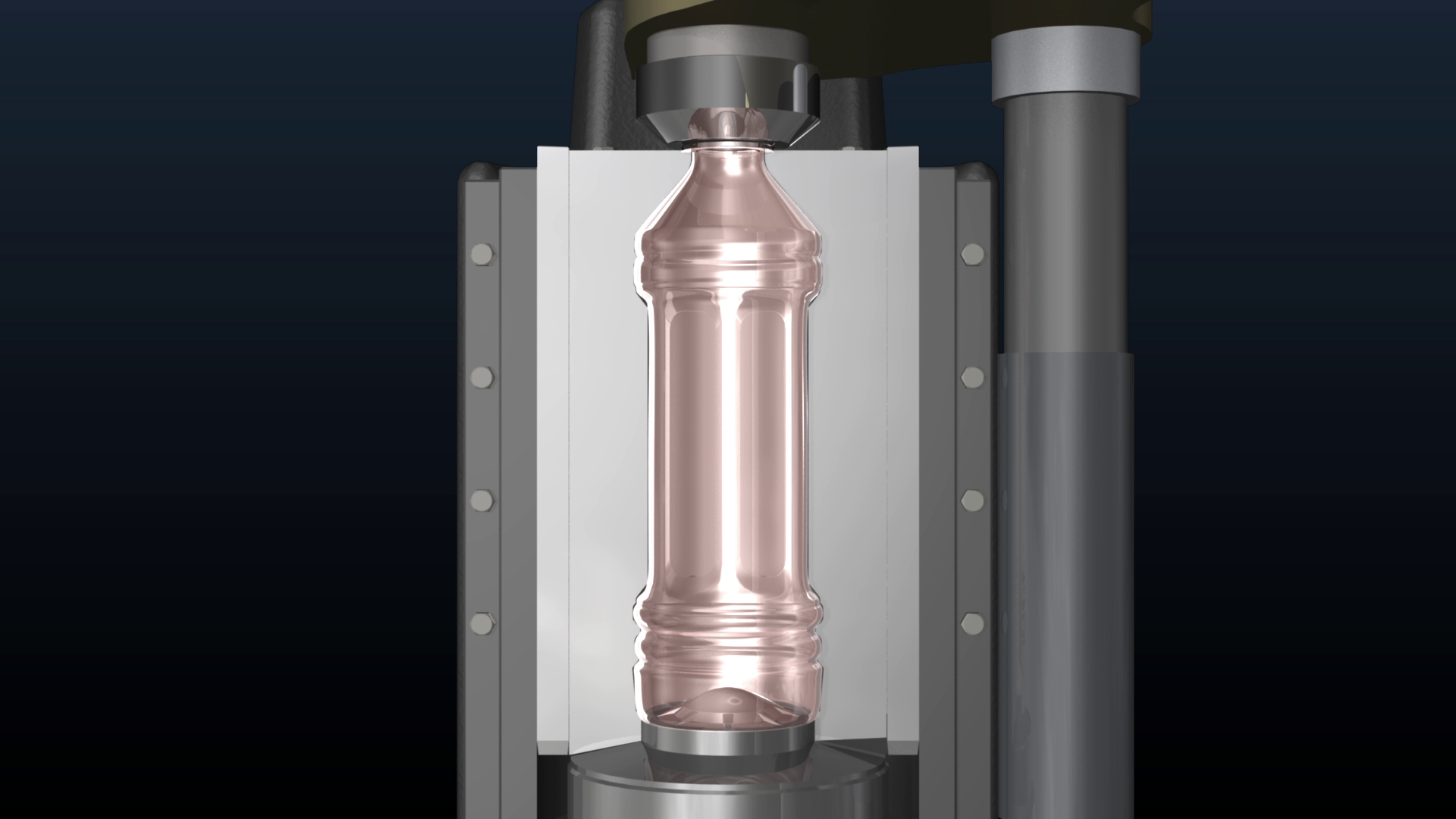

At the blowing station, the preforms are blown into bottles using sterile air. After blow molding is complete and each bottle has passed through the inspection unit, the bottles are then sterilized in the compact bottle-sterilizer.

Blowing Station

Blowing Station

Key features

- H₂O₂ sterilization solutions: Saving energy, water, and resin

- No need for bottle water rinsing

- Applicable for ultra lightweight and flexible bottle designs

- Heat from blow molding process re-used for preform and bottle decontamination

Advantage 1: Space saving

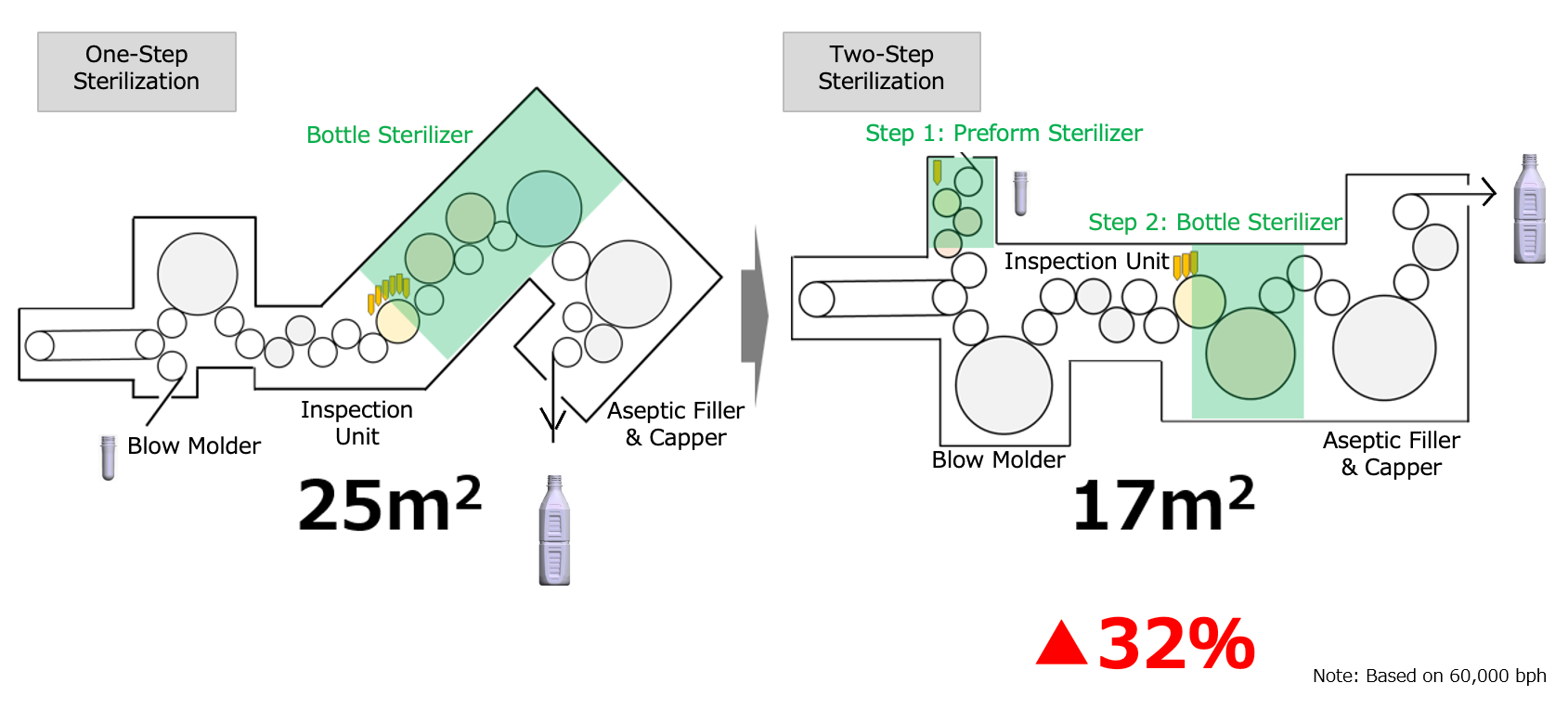

By making the sterilization equipment more compact, the installation footprint can be reduced by approximately 30%. This enables beverage manufacturers to optimize limited factory space more effectively.

Advantage 2: Energy saving

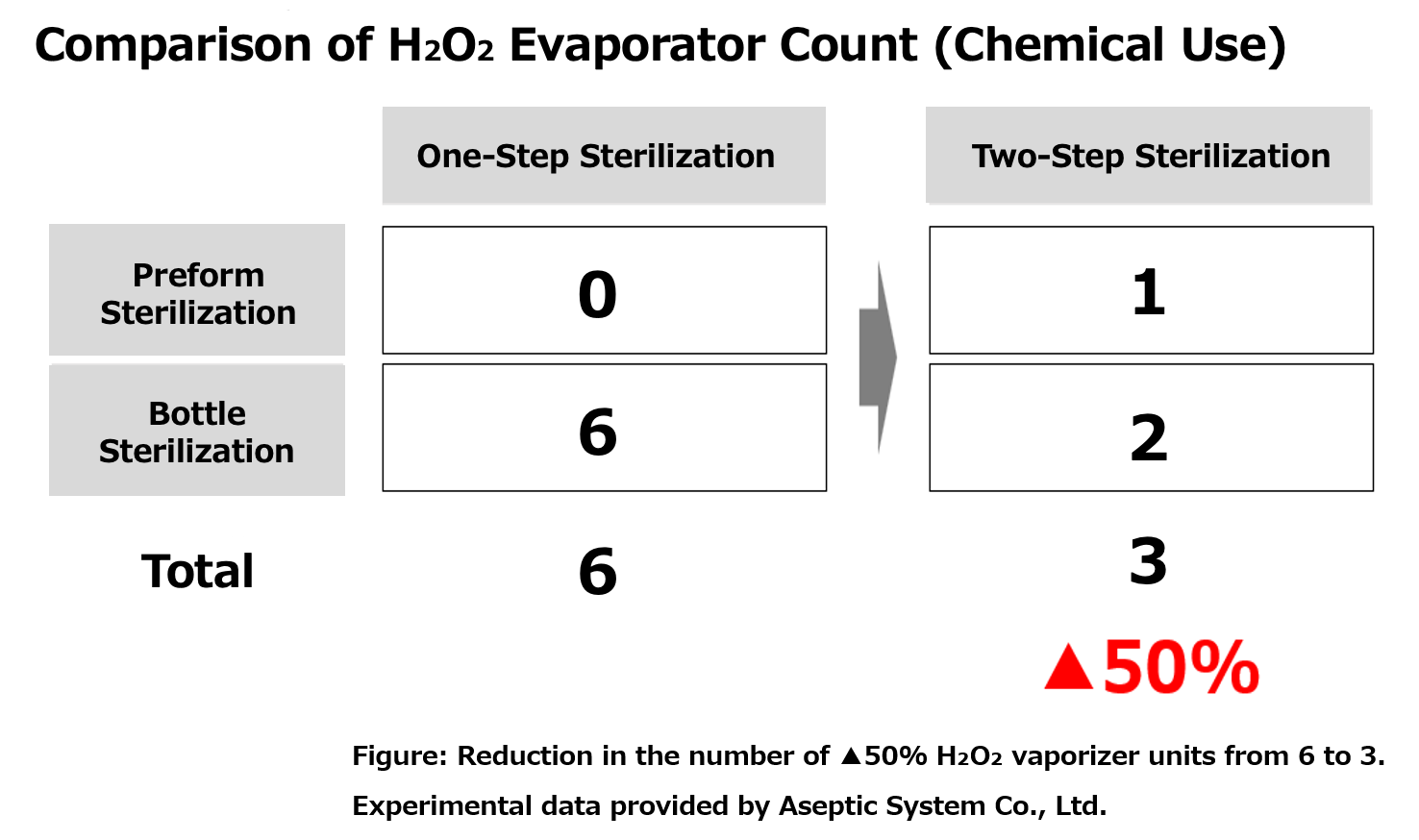

Because the surface area of the preform is much smaller than that of a fully blown bottle, the two-step system cuts overall H₂O₂ usage and associated energy consumption by approximately 40%, and reduces the number of H₂O₂ evaporators from six to three—achieving a 50% reduction in chemical demand—maintaining high aseptic standards.