Hydrogen-peroxide aseptic PET filling with global market leadership

Aseptic Filling Machine for PET Bottles— Proven Sterility, Eco-Ready Performance

Since introducing Japan’s first hydrogen-peroxide aseptic filling machine for PET bottles in 1994, DNP has helped beverage manufacturers safeguard product quality, improve line efficiency, and minimize environmental impact. Today more than 200 of our machines run worldwide—including 60% of the domestic market—each backed by a comprehensive catalogue of PET preforms tailored to diverse bottle concepts.

Table of contents

Video: Japan's highest quality aseptic filling system for PET bottles (0:35)

Overview of our aseptic filling machine for PET bottles

Building on aseptic technology refined since 1972, DNP integrates advanced packaging expertise to ensure reliable material and system compatibility. With decades of engineering experience, we deliver robust, high-uptime layouts supported by DX tools for real-time line feedback and rigorous analysis based on hundreds of installations.

The result is a complete aseptic filling solution embodied in our PET bottle filling machines—delivering the top-tier levels of sterility with minimal environmental impact. Proudly designed and manufactured in Japan with world-renowned craftsmanship, these machines meet diverse customer needs and keep producers future-ready.

|

DNP's aseptic PET filling machine |

Key machine metrics

- Products: Tea, coffee, juice, beverages with pulp or particles, water and CSD (carbonated soft drinks)

- Bottle sizes: 100-2,000ml

- Mouth diameter: 28-38mm (screw and sports caps)

- Installations: Over 200 aseptic filling systems installed (Top share in Japan: over 60%)

- FDA approved: 10 systems (First rotary-type approval in 2005)

- Patents related to asepsis: Over 400 registered

Our aseptic filling technologies

Two-step sterilization — lower TCO

DNP has introduced a next-generation aseptic filling system for PET bottles, featuring a proprietary Two-Step Sterilization process that integrates both preform and bottle decontamination. This innovation has significantly reduced the system footprint and total cost of ownership (TCO). Recognized as one of the most sterile and reliable aseptic filling technologies globally, the Two-Step Sterilization system sets a new benchmark in beverage safety and efficiency.

Key features

- H₂O₂-based dry sterilization: Reduces energy, water, and resin usage

- Maximum filling speed: Up to 72,000 bph

- Compatible with ultra-lightweight and flexible bottle designs

- Utilizes residual heat from blow molding process for preform and bottle sterilization

Video: Two-step sterilization (1:48)

Green Aseptic™ — sustainability

Green Aseptic™ is an innovative non-thermal sterilization technology that combines medium-pressure UV lamps with sterilization filters. This patented technology has significantly advanced decarbonization and energy efficiency in liquid processing systems for both low- and high-acid beverages.

Key features

- Two-step dry sterilization: Minimizes chemical usage, maintains high performance, and maximizes output

- Scalable production of ultra-low carbon water

- Cutting-edge sterilization technology reduces CO₂ emissions and energy use

- Non-thermal sterilization and aseptic blending reduce energy consumption of UHT sterilizers by approx. 80% (at 5 x dilution)

|

|

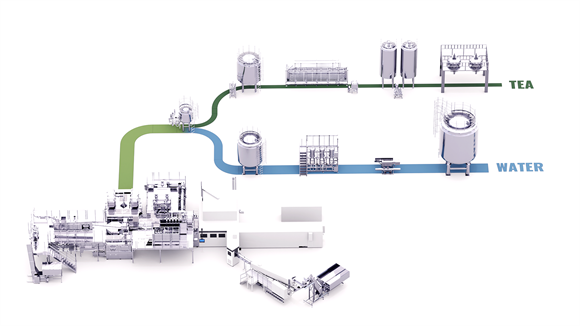

Green Aseptic system overview

Video: Green Aseptic (2:38)

Case studies: tea, juice & water filled with our aseptic filling machine for PET bottles

Tea filling machine case study — 36,000 bph PET bottle line at Shizuoka soft-drink plant (Japan)

|

|

A major beverage producer in Shizuoka began commercial tea production in April 2024 using DNP’s Green Aseptic PET-bottle system. Concentrated tea extract is first heat-sterilized in a compact UHT sterilizer and then diluted with sterile water produced by non-heat sterilization that combines medium-pressure UV lamps and 0.1 µm sterilization filters. After aseptic blending, the line fills 500ml bottles at 36,000bph, with the same non-heated sterile water replacing all conventional rinsing steps. Three media-fill runs of over 10,000 bottles each showed zero spoilage. The process also reduces energy consumption and CO₂ emissions by approximately 80 %, setting a new sustainability benchmark for low-acid beverages.

Juice filling machine case study — 54,000 bph PET bottle line at Asahi Nagoya (Japan)

|

|

Asahi Breweries’ Nagoya factory commissioned DNP’s aseptic PET bottle filling system in April 2021 to produce carbonated and non-carbonated beverages for its Mitsuya Cider, Wilkinson, and Calpis brands. An energy-saving blow molder and aseptic carbonation filler sterilize bottles with H₂O₂ gas at around 50°C, while a 30 m³/h UHT sterilizer feeds product for filling 500ml at 54,000 bph (20,000 bph for 1.5L), where bph refer to bottles per hour; media-fill tests of over 30,000 bottles confirmed sterility with no spoilage. DNP’s patented CSIP technology runs CIP and SIP simultaneously in less than two hours per changeover, and by eliminating the pasteurizer and using normal-pressure PET bottles, the system reduces H₂O₂ usage by approximately 40%, reduces the total cost of ownership, and cuts CO₂ emissions.

Water filling machine case study — Nongfu Spring aseptic filling for infant mineral water

|

|

In 2015, Nongfu Spring—China’s largest packaged-water brand, introduced a 1L natural mineral water for infants using DNP’s aseptic filling system for PET bottles. The system sterilizes bottles and caps without chemicals and cleans the aseptic chamber using sterile water. Sterility was validated for Nongfu’s uniquely shaped, easy-grip blow-molded bottle. Operating at 54,000 bph, the shelf-stable product eliminates the need for chilled logistics, helping reduce both TCO and CO₂ emissions while supporting the brand’s “natural & healthy” positioning.

.png)

.png)