Exterior Films for Automobile Body Parts

DNP offers exterior grade films with excellent formability for complex shapes and large size parts, like bumpers and tailgates. Available finishes include solid and metallic colors, high gloss & matte finishes, as well as graphical patterns. It also features high scratch resistance and weatherability which meets OEM’s requirements. As a paint alternative, our exterior film contributes to CO2 reduction and supports carbon neutral society.

Video:DNP's Exterior Films(42s)

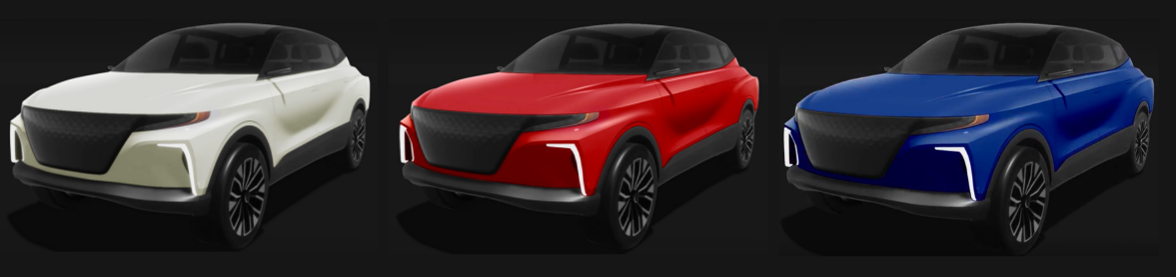

Versatile design options

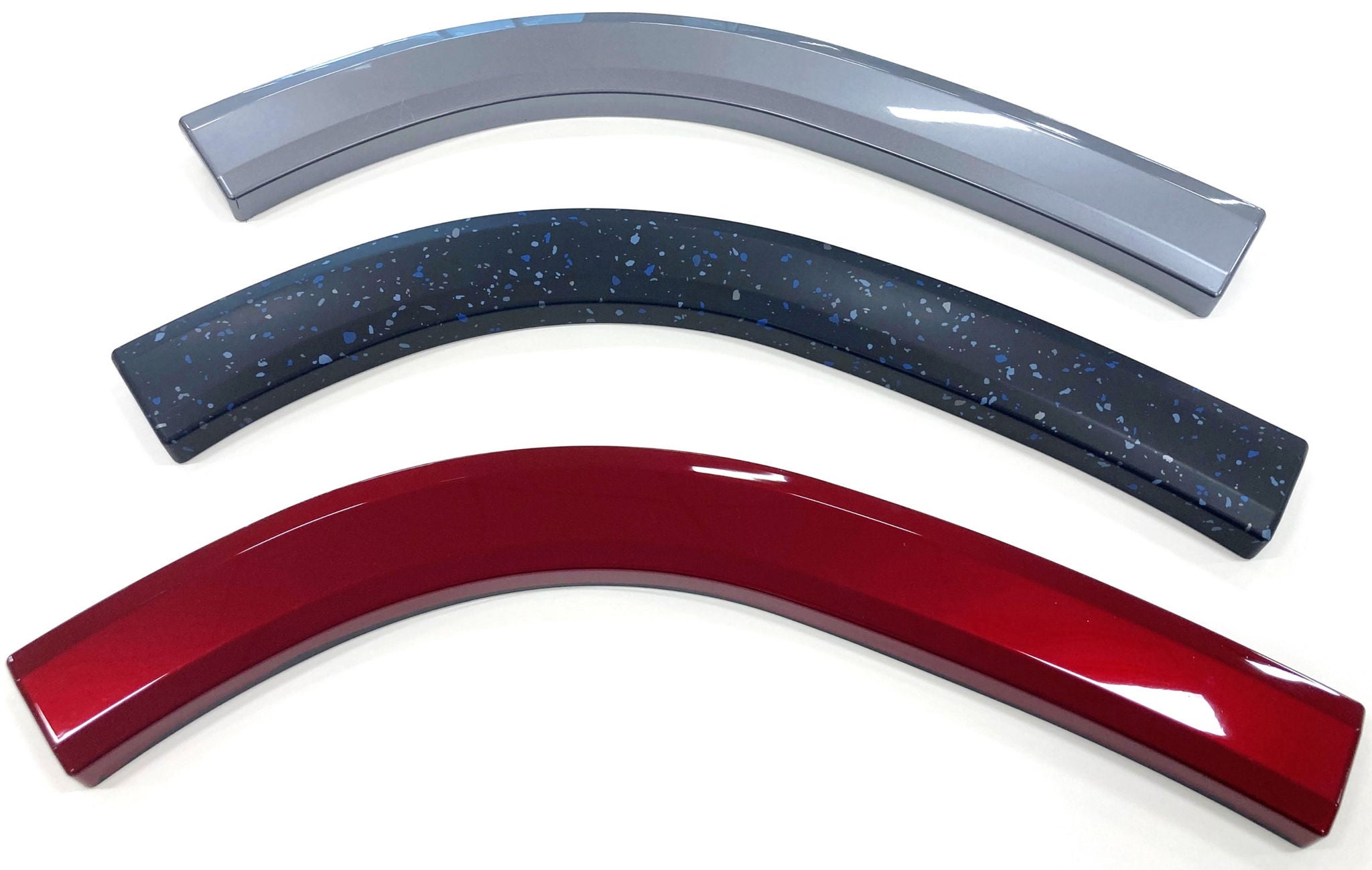

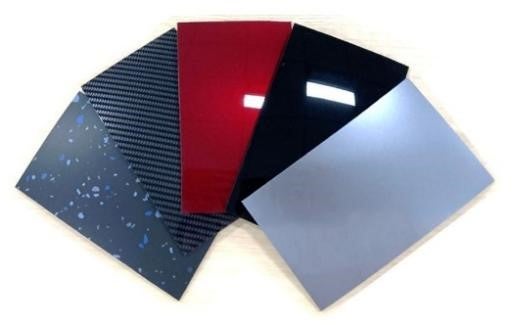

DNP offers not only solid colors but also metallic finishes that replicate the look of spray painted automotive body parts. Metallic colors are achieved using the same metal flakes as paint. By controlling the orientation of the metallic flakes, it can express angle-dependent color shifts like painted surfaces. Applying multiple printed layers enables rich and deep color expression.

Additionally, DNP offers graphic design accents for parts such as fenders and garnishes. Graphic designs are difficult to achieve with paint and unique advantage of film decoration. DNP’s in-house designers can propose designs tailored to each customer’s needs, including wood grain, carbon fiber, and gradational effects. Finishes are available not only in gloss, but also in matte and textured surfaces.

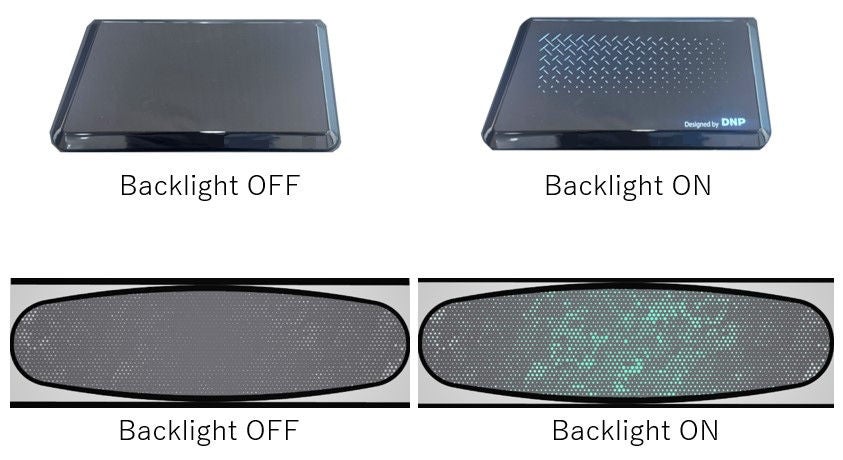

In recent years, with the rise of EVs, the need for heat dissipation function of front grille has been decreasing, and it is being used as a decorative design element. DNP has introduced a digital printing system well suited for front grille applications. Unlike conventional printing machines, digital printing does not require cylinders, allowing for film application on long parts such as front grilles. In addition, this system is suitable for expressing fine metallic appearance, sharp edges, and narrow lines.

It is also ideal for producing light transmitting design effects. Compared to laser etching on painted surfaces, film decoration offers advantages in production speed and yield improvement. Furthermore, since digital printing does not require cylinders re-manufacturing, design adjustments can be made quickly and easily by simply modifying its data.

With film decoration, the appearance can be easily changed by replacing only the film, offering wide options for minor model changes and grade management.

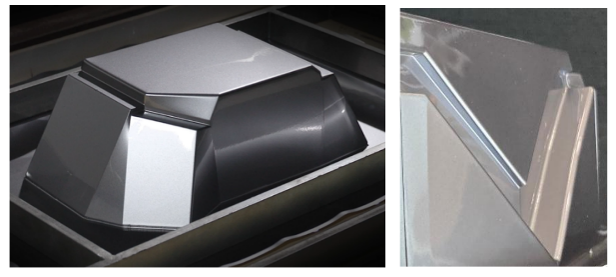

Excellent formability

The film designed for body parts maintains consistent color tones even when stretched up to 2.5 times. Since it also conforms to undercuts, the injected resin will not be visible through gaps when assembled with other parts. Despite its excellent formability, DNP’s topcoat is a pre-cured type and requires no post-processing such as UV irradiation at the customer's production line.

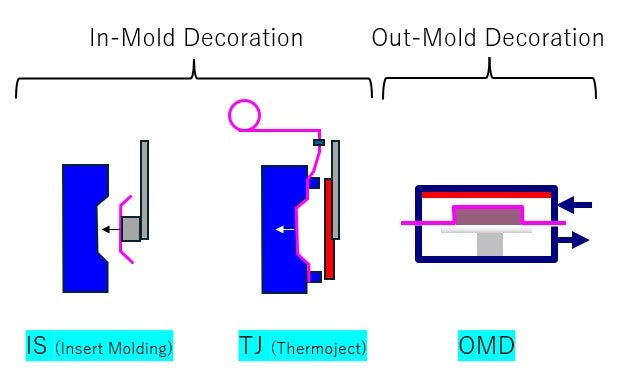

DNP offers film specifications tailored to the customer’s processing method, whether In-Mold or Out-Mold decoration.

In-Mold Decoration

A decorative film is placed inside the mold, where it adheres to the plastic resin during the injection molding process.

Insert Molding Lamination (IML):

The film is pre-formed using a vacuum forming machine to create an applique which is then placed into the mold cavity prior to injection.

Thermoject (TJ) / In-Cavity Process:

The film is vacuum formed inside the mold cavity right before the injection molding process.

Out-Mold Decoration

Applying the film after injection molding.

A film with Pressure-Sensitive Adhesive (PSA) is applied to the molded part using vacuum and pressure forming machines.

Additionally, for processes such as In Mold Coating or 2K molding, which a protective layer is applied by the customer, DNP offers films that adhere well to the protective layer.

Long lasting durability

The film provides long lasting durability for exterior parts exposed to prolonged sunlight. Its topcoat features a self-healing function that naturally repairs minor scratches and enhances vehicle maintainability.

For deeper scratches that reach the substrate, the surface can be restored through conventional spray-painting repair methods.

Sustainability & Recyclability

It is said that the painting process accounts for 25% of the CO2 emissions in automotive manufacturing. Compared to conventional painting, film decoration can reduce CO2 emissions and contribute to achieving carbon neutrality.

Automotive body parts made from plastic resin are typically made using polypropylene. By using polypropylene as the base material of decorative films, DNP supports mono-material construction, which enhances recyclability.

Additionally, film decoration effectively conceals rough surfaces caused by recycled resin. There is a potential to increase the application rate of recycled materials in a vehicle.

Please visit our Mobility Solution website

Here we provide our vision and latest news about our development. Also, we introduce various products, services, and our actions which can contribute to the evolution of mobility and mobility society.