PET瓶無菌填充技術

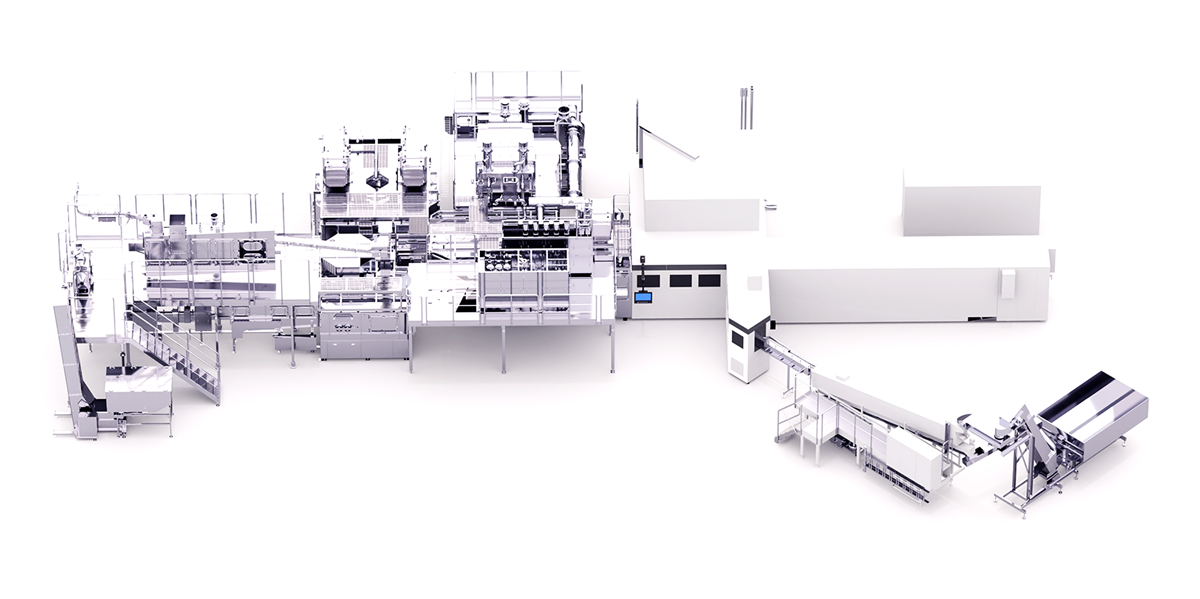

高效能環保 PET 瓶無菌填充系統

・ Complete aseptic filling systems providing the most sterile and ecological way of ensuring superior product quality.

・ Proudly developed and manufactured in Japan since 1972 with world-renowned workmanship and attention to detail.

・ We offer trusted aseptic filling solutions to meet customer requirements.

High productivity, high quality and sustainable aseptic filling system

|

|

Overview of our aseptic filling system

Key system details

- Products: Tea, coffee, juice, beverages with pulp or particles, water and CSD

- Bottle sizes: 100-2000ml

- Mouth diameter: 28Φ-38Φmm (screw and sports caps)

- Installations: >200 aseptic filling technology solutions (Top share in Japan: >60%)

- FDA approved: 10 systems (First approval for rotary type in 2005)

- Registered patents on Asepsis: >600

|

|

High quality – key assurances

- High sterilization effect of preforms, bottles, caps and chamber: B.atrophaeus spores ≧ 6 Log reduction

- Chamber sterilization: PAA & H₂O₂ sterilization (Maintaining high aseptic performance for more than 20 years)

- Failure rates by media fill tests: Less than one contaminated bottle per 60,000 inspected bottles

- Food safety and transparency: No need for preservatives

- Full traceability: All filling, capping, and CCP data are recorded every second

- Net weight filler for high accuracy

- Reliable and robust capping by servo motors

- Made in Japan

|

|

Key benefits

|

|

Our aseptic filling technologies

F₀ Solution & CSIP – high productivity

DNP’s aseptic filling system achieves market-leading productivity by pairing two proprietary sterilization innovations—F₀ Solution and CSIP—with proven high-speed line design.

Key features

- High speed aseptic filling system: Up to 72,000BPH (Bottle Per Hour)

- High Efficiency: >98%

- Faster changeovers: 1.0hr. (CSD), 1.5hr. (High acid), 2.0hr. (Low acid)

- Aseptic changeover: Product switching while maintaining aseptic conditions

- Production duration time: >150h for low acid products

F₀ Solution

F₀ Solution is an innovative way to significantly reduce SIP process time compared to conventional ones while maintaining aseptic performance. It can be applied to almost any aseptic processing equipment and filling machine that performs the SIP process, including UHT sterilizers, aseptic tanks, filling machines, and sterile air filters. F₀ Solution not only enhances productivity but also minimizes environmental issues by reducing steam usage and CO2 emissions.

F₀ Solution

CSIP

CSIP performs CIP and SIP simultaneously. This eliminates the need for traditional SIP processes and allows only high temperature, short duration CIP to be used between productions. Being constantly monitored, aseptic performance is maintained and allows quick changeover for the next production.

CSIP

Two-Step Sterilization – lower TCO

DNP launched a new aseptic filling system for PET bottles with a Two-Step Sterilization system that combines preform and bottle decontamination. This has successfully reduced the footprint and TCO of aseptic filling systems. The Two-Step Sterilization process is one of the most sterile and reliable aseptic filling systems in the world.

Key features

- Floor space requirement for blow mold filling area reduced by approx. 30%

- Reduction of approx. 40% in H2O2 consumption for bottle sterilization

- No need for bottle water rinser

- Applicable for ultra lightweight and flexible bottle designs

- Protect the customer's brand with high sterility that cannot be achieved by preform sterilizer alone

Two-Step Sterilization

Green Aseptic™ – sustainability

The Green Aseptic™ system is a new non-thermal sterilization system that combines medium-pressure UV lamps with sterilization filters. This patented aseptic filling technology has enabled significant decarbonization and energy savings in liquid processing equipment for low and high-acid beverages.

Key features

- Mass production of water with almost zero carbon emissions

- Reduction of CO₂ emissions: Advanced, patented technology that reduces energy consumption.

- Sterile blending using heated and non-heated sterilized liquids

- Energy-saving compact UHT

- Annual maintenance to ensure system performance

Green Aseptic™

N₂ Hood – nitrogen flushing

N₂ Hood is an in-line nitrogen-flushing module that surrounds each PET bottle with a dedicated hood immediately after filling, displacing more than 90% of the head-space air with sterile N₂ before the cap is applied.

Key features

- Maintains > 90% nitrogen replacement even at high line speeds of up to 72,000 BPH

- Delivers delicious beverages to customers for long periods of time

- Extended shelf life: Maximum suppression of oxidation and deterioration of contents

- Bottle weight reduction possible

- Reduction in ascorbic acid content possible

|

|

Aseptic CSD – carbonated filling

DNP’s Aseptic CSD fills high-CO₂ beverages in PET bottles without a downstream pasteuriser, dramatically reducing water, steam and floor-space usage. It still delivers full sterility while lowering packaging costs and enabling lighter, more sustainable bottle designs.

Key features

- Runs on non-crystallised-neck aseptic PET bottles, cutting production costs

- Employs a fully sterile carbonator for superior microbiological quality

- Requires no downstream pasteuriser, saving floor space, water and steam utilities

- Capable of processing high-CO₂, highly carbonated beverages

- Can produce carbonated beverages containing milk ingredients and fruit juices

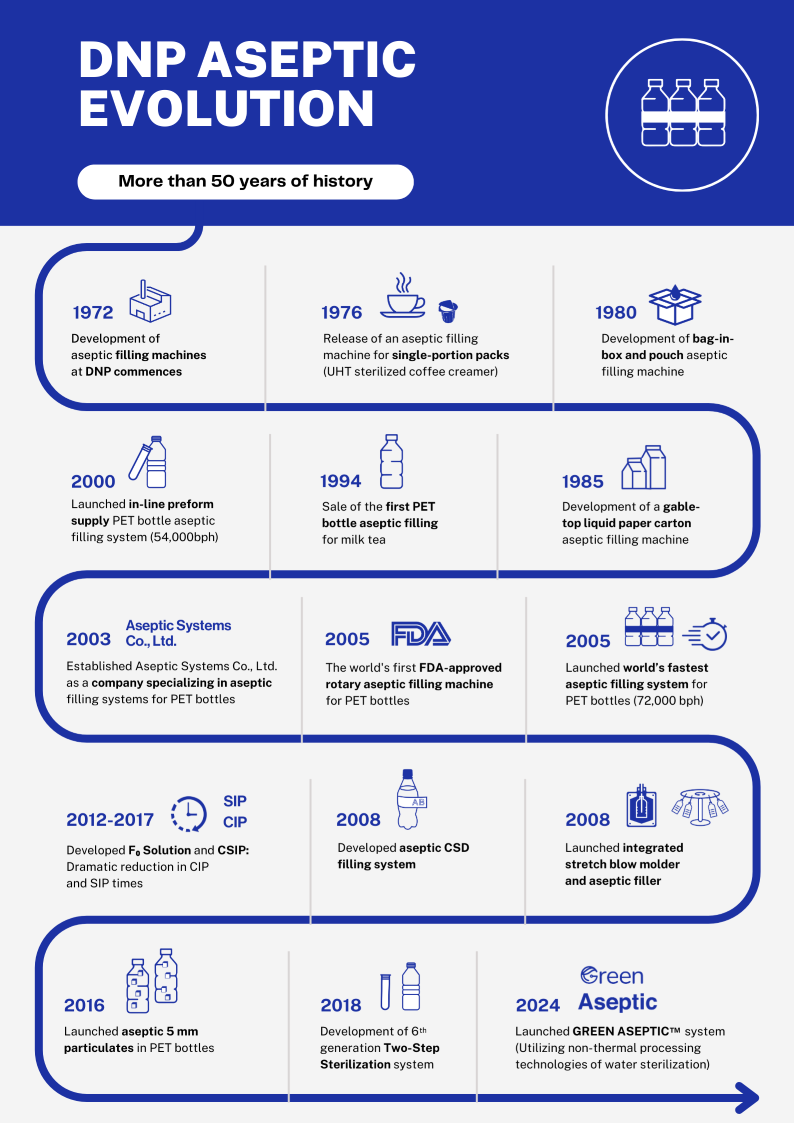

History

DNP’s first aseptic filling machine launched in 1976 to produce single-use coffee creamer packs. The system was designed to allow the UHT sterilized coffee creamer to be filled and sealed in a hydrogen peroxide-sterilized lid and base within an aseptic chamber. This concept has been the basis for the development and sale of various aseptic filling systems (PET bottle, Carton, Cup, Pouch, BIB, etc.) that use hydrogen peroxide sterilization for the last 50 years.

|

|

References

If you would like to gain a better understanding of what makes DNP Aseptic Filling Systems unique, please read these articles published in International Bottler & Packer, one of the world's leading magazine for the beverage packaging industry. You will soon understand why our systems continue to be chosen by and respected by beverage professionals worldwide.

|

|

|

|

|

|

|

|