DNP’s Japanese Space Food Packages: Supporting Astronaut Performance Through Nutrition

Have you heard of Japanese Space Food? It was developed to support the physical and mental health of Japanese astronauts staying on the International Space Station (ISS). DNP manufactures its packaging to keep contents hygienic during long space stays and to allow for easy eating straight out of the container. Let's explore the secrets of DNP's Japanese Space Food Packaging, which has passed rigorous inspections to become Japan Aerospace Exploration Agency (JAXA) designated packaging.

- Space food that supports the physical and mental health of astronauts

- Safe, convenient, and appetizing! High-performance packaging made possible by DNP's technological capabilities

- DNP: A pioneer in private sector food development for space

|

|

Characters

|

|---|

Katsujii... Kinzoku Katsujii is like a living encyclopedia: his career as a movable type spans more than 100 years. Here, he shares his extensive knowledge of the DNP Group, teaching all kinds of things with his many years of experience.

|

|---|

Tonbo-chan... A character born from the tonbo register marks* used to align printed materials. She has a meticulous personality, hates anything misaligned, and supports Katsujii with her careful attention to detail.

- *Register marks: A printing term for registration in multi-color printing refers to the precise positional accuracy when overlapping color plates. This alignment is achieved using register marks known as "tonbo."

Space food that supports the physical and mental health of astronauts

Space development has been gaining momentum again in recent years, with NASA announcing the "Artemis Project"*1 in May 2019 and JAXA's "SLIM" probe becoming the fifth country to successfully land on the moon in January 2024.

- *1 Artemis Project: A lunar exploration program led by NASA, with the goal of a future manned exploration of Mars.

As of late 2023, seven astronauts have been living on the ISS, orbiting roughly 400 kilometers above Earth. For these astronauts, who live in a confined space for about six months at a time, food is an important factor in maintaining their physical and mental health. Inadequate consumption or poor nutritional balance could hinder their mission. With future developments anticipating even longer stays in space, the importance of food will likely continue to grow.

There are currently over 300 types of space food! These include "standard meals" provided by the United States and Russia, and "bonus meals" that individual astronauts can choose to take with them. Bonus meals carried on board the ISS are developed to suit astronauts from different countries and often reflect their culinary cultures.

All Japanese-made bonus meals, known as "Japanese Space Food," are certified and managed by JAXA. There are 56 items available (as of April 2024), including curry, ramen, mackerel with miso, yokan (sweet bean paste), and fried chicken. Some of these have even been provided as bonus meals to international astronauts.

To obtain certification, Japanese space food must meet strict standards, including long-term storage at room temperature, safe consumption directly from the container without spillage in zero gravity, and compatibility with ISS cooking facilities. Naturally, advanced technology is required to manufacture such packaging, and JAXA designates six packaging types for food manufacturers.

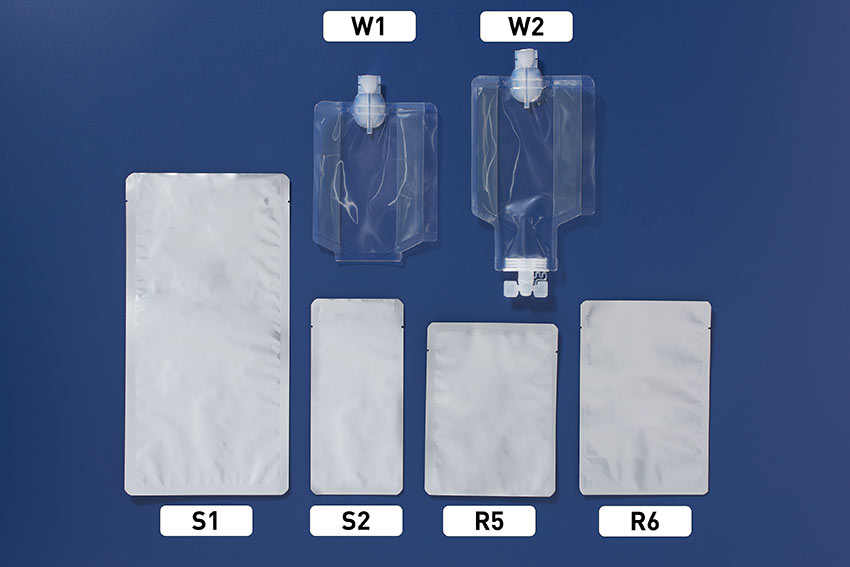

In fact, DNP developed and manufactures these six packaging types:

|

These are the six types of JAXA approved packaging. S1 and S2 are outer bags for space food; R5 and R6 are retort pouches for ready-to-eat meals; W1 and W2 are pouches with inlets for rehydratable foods. |

Safe, convenient, and appetizing! High-performance packaging made possible by DNP's technological capabilities

DNP's involvement in packaging for Japanese Space Food began in 2001 when it was appointed as the developer for the Japanese Space Food Development Project.

Even then, DNP held one of the top shares in the domestic food packaging market, with the technology and expertise to meet the various needs of manufacturers and consumers. In particular, the company's proven success in developing Transparent Barrier Film, a functional film that prevents the permeation of gases like water vapor and oxygen, led to its recommendation to JAXA by a food manufacturing industry association.

A particular challenge in developing "Japanese Space Food Packaging" involved creating a pouch with a water inlet for rehydratable foods. Rehydratable foods are soups or hot dishes prepared by adding water. While these foods are important for allowing astronauts to enjoy meals similar to those on Earth, they face strict requirements regarding transport, preparation, and consumption.

One challenge was balancing the barrier properties that would protect the quality of the contents over long periods of storage with the transparency that would allow the contents to be seen so that astronauts would find the meals appealing. Up to that point, transparent packaging often meant reduced barrier properties. However, DNP successfully manufactured packaging that achieved this by applying advanced vapor deposition and converting technologies (material processing technologies) developed through IB-FILM.

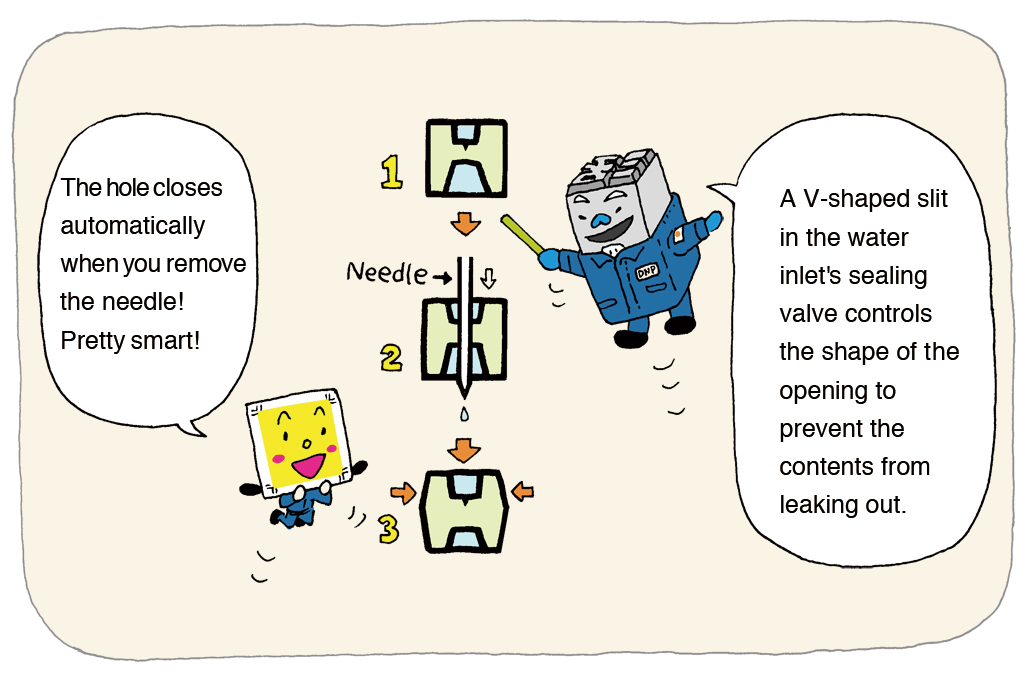

Another challenge was creating a pouch with a water inlet compatible with the ISS's water dispenser. The ISS is equipped with a dispenser that uses a needle to pierce the pouch's water inlet, requiring that the pouch must not leak during or after water is added.

So DNP began developing prototypes in cooperation with JAXA. A team of specialists in various fields was formed to design the optimal container, including materials with gas barrier function, molded product design and processing, and retort packaging.

One of the most ingenious aspects of the resulting design was the internal structure of the water inlet, which prevents backflow even after the needle is removed. If contents were to leak from the hole opened during water injection, it could damage precision equipment on the ISS. To prevent leakage or backflow, the inner diameter of the water inlet was narrowed, and the sealing valve was compressed.

|

|

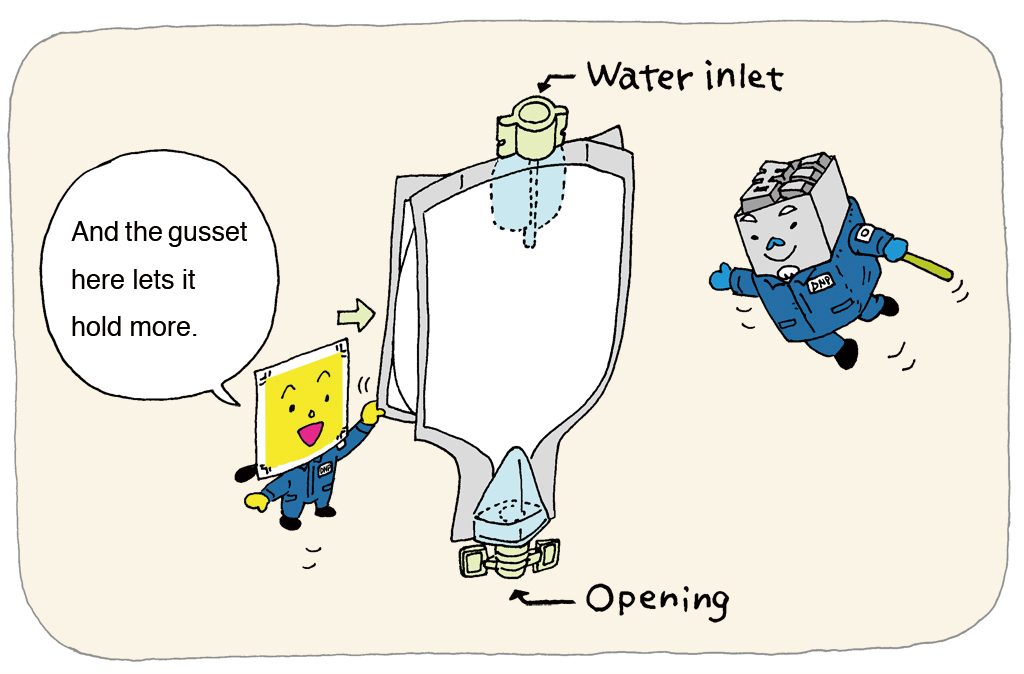

DNP has also taken into consideration the shape of the containers to make them more convenient for astronauts to eat from. For example, the opening was enlarged so broth and solid ingredients could be consumed together. Gussets, which add depth to the container, were incorporated to increase capacity while being easier to hold. Also, various innovations were included so that the entire package was made lightweight and compact to reduce load, allowing more Japanese Space Food to be transported for long-term missions.

|

|

Thinking from the user's perspective is important, whether on Earth or in space. This design philosophy may be the reason DNP's Japanese Space Food packages, with ongoing customization, have remained JAXA’s designated packaging for over 15 years.

DNP: A pioneer in private sector food development for space

In addition to further enhancing menus, Japanese Space Food aims to fulfill one of JAXA's philosophies of "giving space technology back to society."

One of the ways in which Japanese Space Food can be used to do this is to repurpose it as food for use in times of disaster. Such food has many things in common with space food, such as the need for long-term storage at room temperature and simple preparation. In recent years, foods that have been certified as Japanese Space Food have also been certified as disaster food through a simplified review process by the Japan Disaster Food Society, paving the way for such use.

Additionally, DNP's spouted pouch, applied to pouches with a water inlet, is designed to prevent spills and features a large opening for easy consumption. As such, it is being considered for use in therapeutic diets for bedridden patients or the elderly.

The outlook for space development is increasingly focused on private sector involvement. When ISS operations conclude in 2030, operations for low-Earth orbit space stations are scheduled to be transferred to private companies, with the extensive involvement of domestic companies in JAXA's SLIM probe becoming a hot topic.

If long-term stays in space, including Mars exploration and lunar travel, become a reality, there will be an ever-increasing demand for more advanced technology. To always meet these high demands, it will be important for diverse private companies to enter the space development business and compete while improving their technological capabilities.

Space food, in particular, is often produced in small batches, making it easy for even smaller food manufacturers to get involved, and many companies with aspirations in space development are already participating. DNP, which has been working with JAXA on packaging development for about 20 years, is making the most of its unique expertise and technical capabilities to support the development of new menu items.

Going forward, DNP will continue to act as a pioneer connecting JAXA and private companies with their diverse ideas, while supporting efforts to enrich the diet of astronauts to keep them healthy both physically and mentally.

|

|---|

I had no idea that DNP products are in space!

|

|---|

DNP supports various aspects of life, including food, and will keep on growing!

-

*Please note that the information provided is current as of the publication date.

Last update date: November 27, 2025

May 13, 2024 by DNP Features Editorial Department

Discover more

Related products and services

DNP's Transparent Barrier Film (Open in a new window)

DNP's Transparent Barrier Film is a functional film that has superior moisture barrier and...

DNP's Retort Pouch(Open in a new window)

DNP's retort pouches has been thriving in the food industry since 1975. DNP's flexible pou...