New Transparent Conductive Film Development

Leverages microwaves to create 11 nm-diameter silver wire

Oct3,2023

Dai Nippon Printing Co., Ltd.

Microwave Chemical Co., Ltd.

On October 3, Dai Nippon Printing Co., Ltd. (DNP) in Tokyo and Microwave Chemical Co., Ltd (MWCC) in Osaka, are pleased to announce the development of a transparent conductive film. The balance between high transparency and conductivity has been made possible as a result of MWCC expertise in leveraging microwave irradiation to create silver nanowire with a nanometer (10 -9 meters) level. DNP will commence provision of sample products from December 2023, and going forward the two partners aim to offer the new product for a variety of sensor applications in combination with DNP optical film.

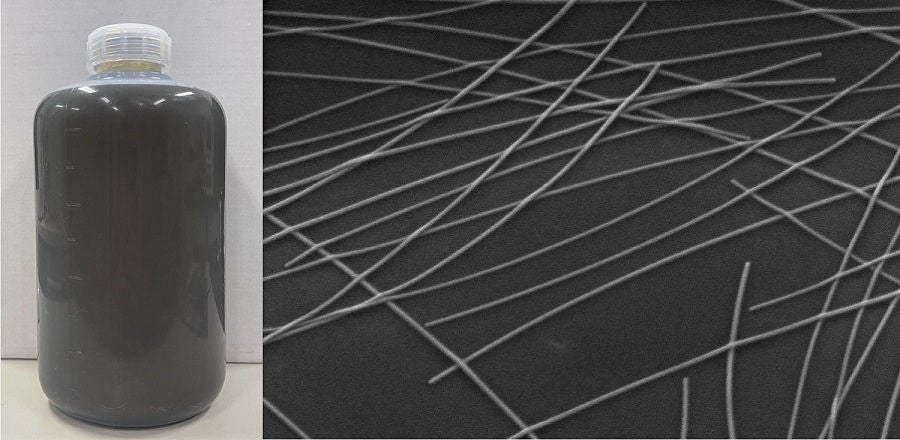

Silver nanowire distribution liquid and FE-SEM image

Silver nanowire distribution liquid and FE-SEM image

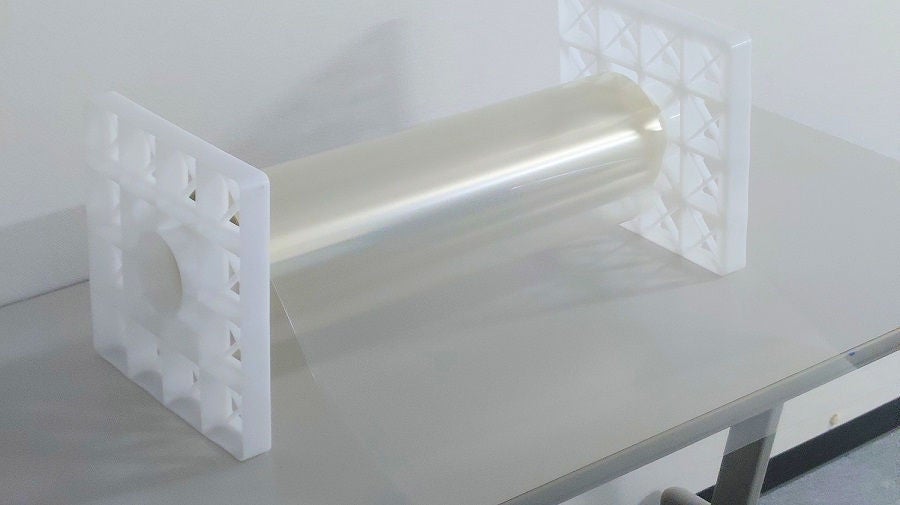

Silver nanowire film

Silver nanowire film

Transparent Conductive Film Features

To date, transparent conductive films have generally required film configuration in a vacuum, whereby a conductive metal oxide, such as Indium Tin Oxide (ITO), is generally applied evenly and at high density to a Polyethylene Terephthalate (PET) film. It has also been necessary to undergo processes such as high-temperature sintering. On top of this, ITO film itself is not flexible, and there is a risk of cracking in the conductive parts due to sudden temperature changes, leading to concerns about workability and durability. In this latest development, DNP has succeeded in developing a transparent conductive film in which a thin film of silver nanowire is uniformly configured at low temperatures by combining our proprietary ink formulation with precision wet coating technology. Low-temperature film formation increases the degree of flexibility when selecting the base material, and as it uses a fibriform material maintains higher durability and flexibility than ITO.

The newly developed transparent conductive film also uses ultrathin silver nanowire with a diameter of 11 nm, achieving both extremely high transmission and low diffuse reflectance1 in visible and near-infrared light. For example, in the sheet resistance range of 30 to 70Ω/sq., or ohms per square: resistance per unit area, the newly developed transparent conductive film maintains higher transparency than ITO.

Also, by applying electricity to the transparent conductive film, the film itself can efficiently generate heat. With this development, when a transparent film heater is applied to Light Detection and Ranging (LiDAR) sensors2, freezing and condensation can be prevented, and detection sensitivity is improved by reducing diffuse reflection. As a result, it will be possible to realize a safe autonomous driving society even in cold weather regions.

Developmental Background

To address this issue, MWCC has improved the crystal control technology that directly irradiates the silver with microwaves, and by growing crystals along the vertical axis. The company has also established a production technology for ultra-thin silver nanowire with a high aspect ratio. This process selectively transfers energy to the silver nanowire, making it possible to reduce CO 2 emissions more efficiently, and in significantly greater dimensions, compared to existing methodologies.

Going Forward

DNP will commence provision of product samples in December 2023. By integrating the newly developed product with functional optical films, such as anti-reflection films and liquid crystal retardation films, which are among DNP’s strengths, we also aim to provide LiDAR sensors for purposes, such as vehicles and autonomous driving, as well as the communication field, in addition to displays.

At the same time, DNP Fellow Norinaga Nakamura will introduce the new product as part of his address on “The Current Status and Future Prospects of DNP's Functional Films,'' at the 14th Highly-functional Material Week to be held at Makuhari Messe, a large convention center in Chiba City, from October 4th to 6th, 2023.

- 1: Diffuse reflectance: Refers to the reflectance of light excluding specular light. Even transparent objects that do not absorb light can cause light scattering internally, reducing their transparency. Silver nanowire with a high refractive index has faced a major challenge from whiteness of their film. In order to address this issue, we have created ultrathin silver nanowire, making it possible to achieve both high transparency and conductivity.

- 2: LiDAR sensors: A technology that measures the distance to an object, the shape of the object, etc. by emitting laser light and using information from the reflected light.

- Product prices, specifications and service content listed in this news release are current as of the date of publication. They may be changed at any time without notice.