DNP to Mass-produce Eco-Friendly Decorative Film for Automobile Interiors

Promoting vehicle recycling efforts

Tokyo, June 4, 2024, Dai Nippon Printing Co., Ltd. (DNP) has established a mass-production technique for environmentally friendly propylene (PP) based decorative film for automobile interiors, in a move which is expected to promote vehicle recycling efforts.

The latest environmentally friendly decorative film will be on display at Automotive Engineering Exposition 2024 ONLINE, with STAGE 1 to be held from May 15 until June 5, and STAGE 2 from July 10 to July 311.

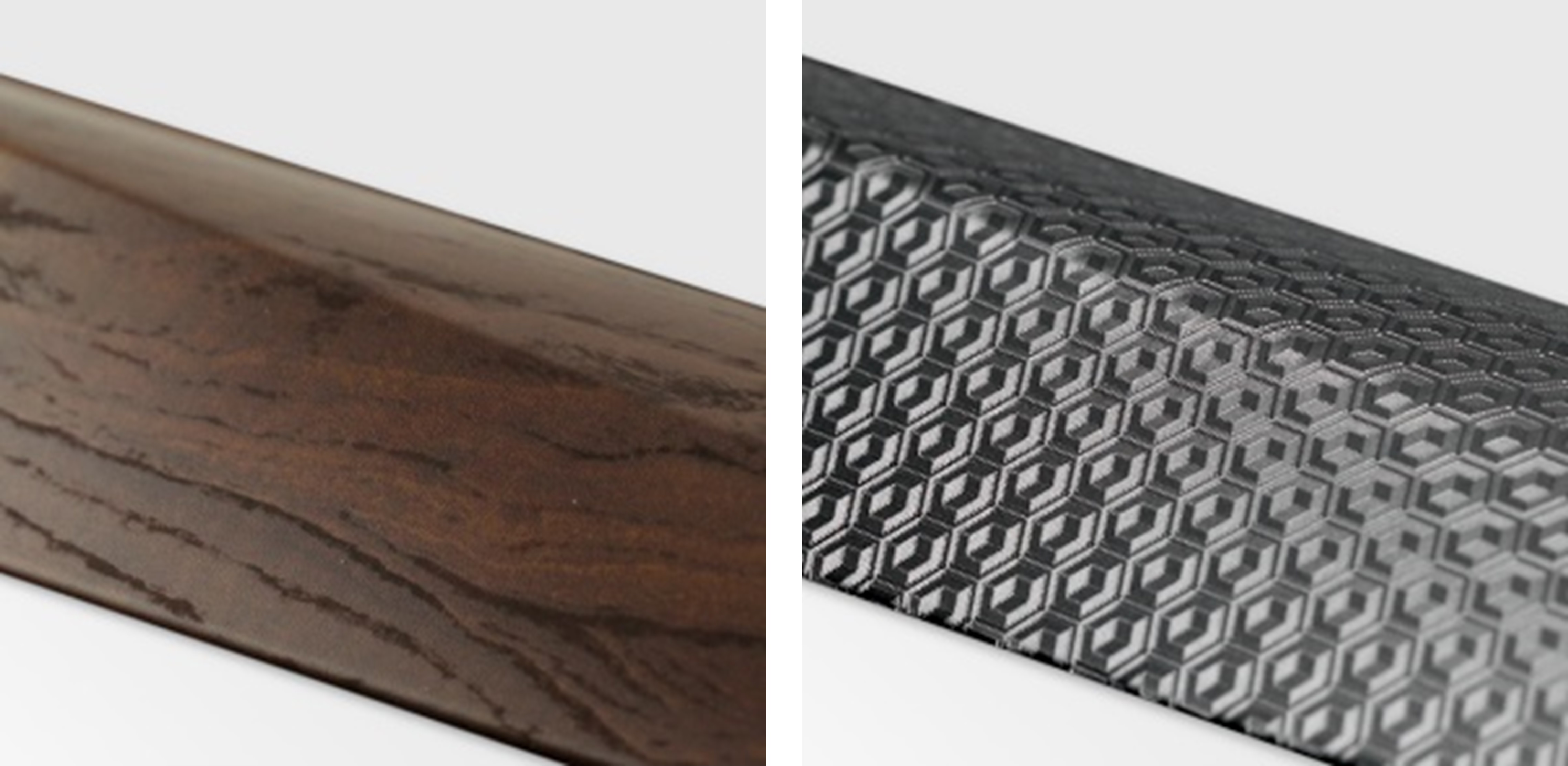

Decorative film for automobile interiors

Background

Approximately 3.5 million cars are scrapped each year in Japan, though following the enactment of the Automobile Recycling Law2 in 2002, more than 95%3 of end-of-life vehicles are now recycled. To date, Automobile shredder residue (ASR), such as plastic waste left after dismantling and shredding have been thermally recycled via incineration.

In Europe, revisions to the Draft Regulations on Sustainability Requirements in Vehicle Design and End-of-Life Vehicles (ELV) Management are being considered, and the use of recycled plastics in vehicles is expected to become mandatory in the near future. Domestic and foreign automobile manufacturers and companies that handle automobile-related parts are taking steps to respond to this situation.

The environmentally friendly decorative film to be mass-produced by DNP capitilises on the long standing in-house development of PP film printing and processing technology. The result successfully achieves film comprising a high quality design and ease of handling for insert injection modling process. PP decorative film produced by DNP is also expected to reduce greenhouse gas (GHG) emissions.

PP is used in large quantities as automobile parts and is suitable for recycling. Further growth is expected in the future, but when used as a base for decorative films challenges have included weak ink adhesion, and the difficulty of maintaining the balance between the high quality design, physical properties and moldability.

DNP has overcome these challenges by leveraging the printing technology and know-how it has cultivated over many years to establish a mass production technology for PP-based automotive decorative films.

DNP Decorative Film Features

- By providing decorative films for automobile interiors based on PP, we will contribute to automobile recycling.

- PP emits lower GHG during raw material manufacturing than the currently commonly used acrylonitrile butadiene styrene (ABS). As a result, it can be expected to lead to a reduction in GHG emissions for vehicle as a whole.

- By applying and developing DNP's converting or material processing technology4, we have achieved an excellent design quality, physical properties, and moldability for PP-based automotive decorative films.

Going Forward

DNP will provide environmentally friendly automotive decorative films that contribute to recycling, mainly to the domestic and overseas automotive industries aiming for cumulative sales of 10 billion yen by fiscal 2030. In addition, as a further environmentally friendly product, DNP has also developed an exterior film that does not require a painting process.

DNP is collaborating with DNP Europe GmbH, DNP America LLC, and DNP Living Space & Mobility (Shanghai) Co., Ltd. to expand its business worldwide, and plans to further accelerate its expansion in the future.

1: For more information about the DNP exhibit, please visit: https://www.dnp.co.jp/biz/eventseminar/event/20173934_4966.html (in Japanese Only)

2: For more information about the Automobile Recycling Law, please visit: https://www.meti.go.jp/policy/mono_info_service/mono/automobile/automobile_recycle/about/recycle/recycle.html (in Japanese Only)

3: For more information about recycling please refer to information from the Japan Automobile Manufacturers Association at https://www.jama.or.jp/operation/ecology/recycle/index.html (in Japanese Only)

4: Converting technology: A processing technology that transforms and combines materials. DNP maintains strengths in processing materials such as films including film forming, coating, laminating, configuration, transfer, slitting, printing, and molding.

*Company and product names mentioned in this news release are the registered trademarks or the trademarks of those companies.

*Product specifications and service content listed in this news release are current as of the date of publication. They may be changed at any time without notice.