DNP Develops Plastic Sheet for PTP for Pharmaceutical Packaging

Combines transparency and moisture absorption

Jun 19, 2025

Tokyo, June 19, 2025, Dai Nippon Printing Co., Ltd. (DNP) has developed a new patented plastic sheet for Press Through Packaging (PTP)1, for pharmaceutical preparations that dissolve in the mouth, such as orally disintegrating (OD) tablets. The new plastic sheet maintains a high moisture absorption rate of 4g/m22, meaning it does not require a desiccant, or drying agent, to prevent quality deterioration due to moisture and humidity. It is also highly transparent allowing the contents to be seen. By combining transparency and moisture absorption, DNP will not only improve the quality retention of pharmaceutical preparations, but also contribute to greater convenience and safety in the medical field.

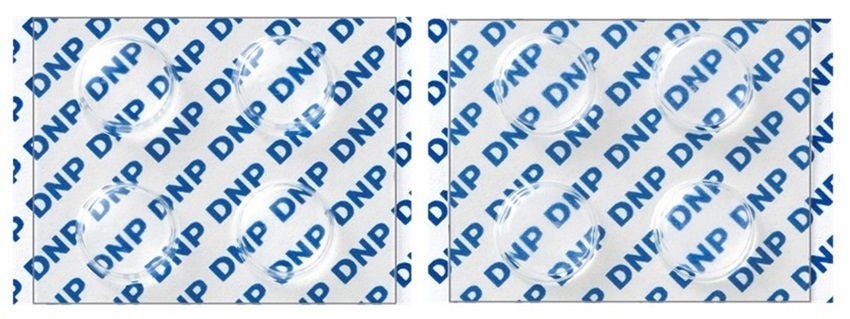

Image of newly developed PTP plastic sheet

Image of newly developed PTP plastic sheet

Background

A feature of OD tablets is that the quality tends to deteriorate when moisture is absorbed. As a result, conventional packaging has required responses such as the use of aluminum blisters3 (covered in aluminum foil) to prevent moisture penetration. These aluminum blisters, however, are not transparent and the contents cannot be seen, which has created challenges such as the increased time and effort required for pharmaceutical manufacturers to inspect the tablets after packaging and for dispensing pharmacies to conduct audits. In case, where aluminum blisters have not been used, it has been necessary to enclose both PTP sheets and desiccants that absorb moisture into aluminum foil pillow-pouch. But, this poses time and cost challenges. In order to solve such issues, DNP has applied its proprietary packaging technology to develop a new, moisture-absorbing, transparent plastic sheet for PTP.

PTP Plastic Sheet Features

1.Maintains pharmaceutical quality through absorption effect

The newly developed plastic sheet for PTP has a moisture absorption performance of 4g/m2 and absorbs any remaining moisture within the PTP pocket. Such high absorption level makes it possible to maintain the quality of pharmaceutical preparations amid concerns for quality due to moisture and humidity.

Conventional sheets are equipped with enhanced moisture barrier properties to prevent external moisture penetration, but have been unable to remove moisture and humidity from inside the packaging. Our PTP plastic sheet has a moisture absorption function built into the packaging itself, making it possible to prevent deterioration in the quality of pharmaceutical preparations.

2.Maintains transparency to ensure visibility of formulations

The newly developed plastic sheet for PTP maintains high transparency even when using moisture-absorbing materials, meaning visibility of the contents is not impaired. As a result, it is easier to check the formulation compared to aluminum blisters that do not allow the inside of the package to be seen. It is also possible to prevent accidental ingestion while improving convenience and safety. When order picking at pharmacies, formulations that are sensitive to moisture can be removed from the pillow-pouch and stored on the shelves, improving the work efficiency of pharmacists.

Conventional sheet without moisture absorption properties (at left)

Newly developedplastic sheet for PTP (at right)

Conventional sheet without moisture absorption properties (at left)

Newly developedplastic sheet for PTP (at right)

3.Achieves both high moisture barrier and environmental friendliness

The newly developedplastic sheet for PTP can add moisture absorption functionality to conventional sheets, and also prevent moisture that permeates from outside the packaging. This improves the moisture barrier of the entire sheet.it also allows for the selection of polypropylene (PP) or polyvinyl chloride (PVC) as the base material for the sheet depending on the requirements of the product. PP is easy to recycle, and selecting this material facilitates an environmentally friendly design.

Going Forward

DNP will supply pharmaceutical manufacturers with plastic sheets for PTP aiming for annual sales of 300 million yen by FY 2030.

We will introduce the newly developed PTP plastc sheet at booth W3-20 at the 27th INTERPHEX JAPAN, the International Pharmaceutical and Cosmetics Manufacturing Expo, to be held on the 4th floor of the West Hall at Tokyo Big Sight from July 9 to July 11, 2025.

- PTP. A method of packaging medicines in the form of a sheet in which tablets or capsules are packed between bottom plastic pocket and top aluminum lid sheet. Pressing firmly on the bottom plastic pocket breaks the aluminum top lid, allowing the medicine to take out one tablet at a time.

- Compliant with JIS K7209:2000 Law B

- Aluminum blister: A non-transparent form of packaging that uses aluminum foil for the container and lid, providing excellent barrier properties against moisture.

- Company and product names referred to in this release are the trademarks or registered trademarks of their respective owners.

- Information contained in this release is current as of the date of announcement, and is subject to change without notice.

- 医薬品包装向けPTP用樹脂シートに関するお問い合わせ → https://biz.mkt.global.dnp.co.jp/l/819623/2025-05-19/5zxmwr