DNP Develops Plastic Film Lid for PTP with Barrier Properties

Replacing the aluminum foil to achieve PP mono-material structure

Jul 7, 2025

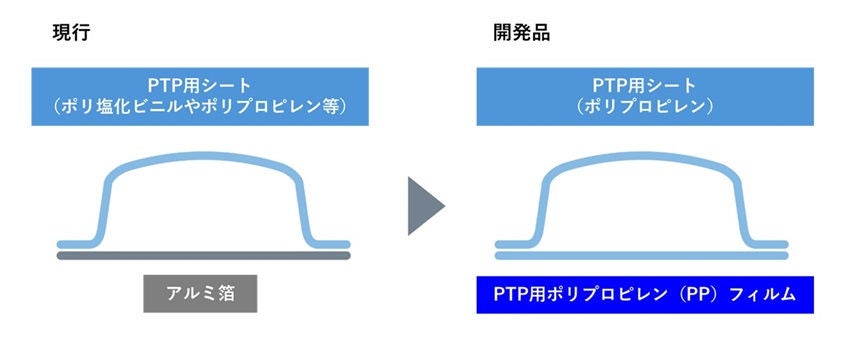

Tokyo, July 7, 2025, Dai Nippon Printing Co., Ltd. (DNP) has developed a new plastic film lid for Press through Package (PTP) 1 making it possible to replace aluminium foil. This has been made possible by substituting polypropylene (PP) for the aluminium foil lid, and providing the PP with barrier properties.

To date, when recycling PTP a process was required to separate the PTP bottom sheet from the aluminum foil lid. By combining the PTP PP bottom sheet with the newly developed PP film lid to create a mono-material package, we have made it possible to answer the needs of the pharmaceutical market via combination of printability and sealability that ensures consumer convenience.

Replacingcurrent aluminum foil lid to PP film lid for PTP

Replacingcurrent aluminum foil lid to PP film lid for PTP

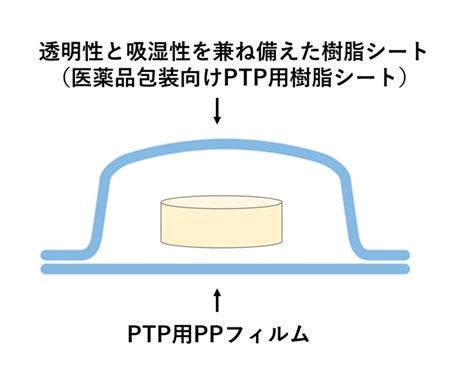

Image of newly developed product

Image of newly developed product

[Background]

The European Union (EU) Packaging and Packaging Waste regulation (PPWR) came into force in February 2025. As a result, the movement towards the introduction of mono-material packaging is accelerating, and pharmaceutical manufacturers are progressively investigating the introduction of recyclable packaging materials in response to the trend towards realizing a sustainable society. As a contribution to these efforts, DNP has developed a PTP PP film lid with adding barrier properties, which can be combined with a PTP PP bottom sheet to create mono-material packaging.

PTP PP Film lid Features

1. Achieving both barrier performance and recyclability

Currently available PP film lid for PTP is specially processed to make it easier to push through the pharmaceuticals packedin the pocket, in a similar manner to aluminium foil lid, but it has been difficult to apply the barrier properties against water vapor. DNP has risen to this challenge, and has utilized proprietary converting(material processing), technology to improve barrier properties and achieve a water vapor transmission rate2 of 0.2g/m2 per day or less3. Recyclability has also been improved by constructing the film from a thin layer of transparent material without using aluminium foil.

2. Satisfies printability and sealability requirements of the Japanese pharmaceutical market

Currently available PP film lid for PTP that satisfies the printability and sealability required by the Japanese pharmaceutical market has lower heat resistance than aluminium foil lid, and causes thermal expansion and contraction. These factors combined to produce problems with the printability required for printing the necessary information on the packaging, and the sealability on the PTP bottom sheet to protect the formulation. In this latest development, by optimizing materials and processing conditions, DNP has successfully developed a PP film lid for PTP that assures printability compatible with various Japanese domestic standards along with the necessary post-printing sealability.

3. Maintains formulation quality by combining with a transparent and moisture absorption bottom sheet

By combining the newly developed PP film lid for PTP with our PTP bottom plasticsheet for Pharmaceutical Packaging4, which prevents quality deterioration due to moisture and humidity during distribution channel. This combined lid&bottom solution make it possibleto improve further barrier performance against water vapor. This allows the quality of pharmaceuticals that are sensitive to moisture to be maintained for a longer shelf life.

Going Forward

DNP will provide the newly developed product to pharmaceutical manufacturers, aiming for cumulative sales of 1 billion yen by FY 2030. DNP will provide product samples along with the PTP plastic bottomsheet for Pharmaceutical Packaging developed in June 2025. DNP will introduce this product at booth W34 at the MEDICAL FAIR THAILAND , Thailand’s leading medical and healthcare exhibition, to be held at BITEC Bangkok. from September 10 to September 12, 2025.

- PTP: A method of packaging medicines in the form of a sheet in which tablets or capsules are packed between plastic bottom pocket and aluminum top lid. Pressing firmly on the plastic bottom pochet breaks the aluminum top lid, allowing the medicine inside to be removed one tablet at a time.

- Water Vapor Transmission Rate: WVTR, the amount of water vapor that passes through 1m2 of film in one day.

- Actual measured value of developed product, not a guaranteed value

- 医薬品包装向けPTP用樹脂シート → https://www.dnp.co.jp/news/detail/20176872_1587.html

- Company and product names referred to in this release are the trademarks or registered trademarks of their respective owners.

- Information contained in this release is current as of the date of announcement, and is subject to change without notice.

- PTP用PPフィルムに関するお問い合わせ → https://biz.mkt.global.dnp.co.jp/l/819623/2025-05-19/5zxmy5