Principles of LiDAR and the Role of Cover for Improving Distance Accuracy

Requirements for LiDAR cover and DNP's proprietary technology are also introduced.

|

|

- What is LiDAR?

- Needs and challenges of long-range sensing in LiDAR

- What is required of LiDAR covers and DNP's proprietary technology

What is LiDAR?

Light Detection and Ranging (LiDAR) is a high-precision laser-based distance sensor. LiDAR can detect the distance to surrounding objects such as terrain, buildings, and pedestrians in three dimensions in real time. LiDAR has a wide range of applications, including mapping and mobile robotics, and is attracting much attention for its use in automated driving.

The most sophisticated automated vehicles on the market in Japan have achieved Level 3: Conditional Driving Automation and are equipped with five LiDARs. Other manufacturers' vehicles, which are equivalent of Driving Automation Level 3, are equipped with one LiDAR system in the front.

Thus, LiDAR is a useful technology for realizing advanced automated driving functions. In the future, LiDAR will become an increasingly important technology to realize more advanced Level 4: High Driving Automation and Level 5: Full Driving Automation.

*The above information is as of December, 2023.

Principles of LiDAR

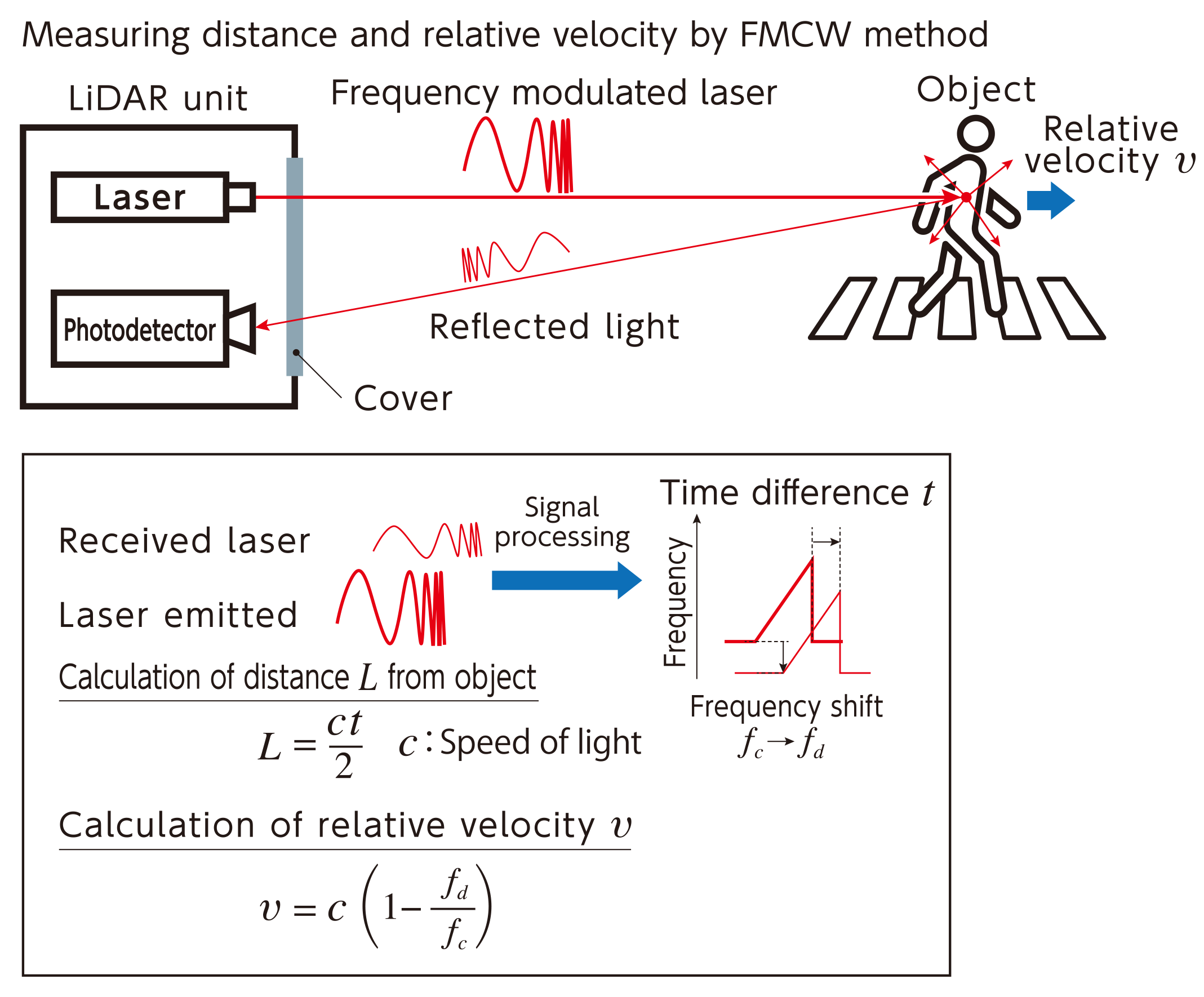

There are two types of LiDAR systems currently in practical use, Time of Flight (ToF) system and Frequency Modulated Continuous Wave (FMCW) system, which differ in their ranging methods.

The principle of ToF method is very simple. First, LiDAR emits a laser beam toward the point to be measured. If there is an object ahead, part of the laser light is reflected off the surface of the object and bounces back to LiDAR. LiDAR precisely measures the time between the emission of the laser beam and the reception of the bounced beam. The distance to the object can then be accurately calculated from the time it takes the laser beam to travel back and forth between the object and the device. The mainstream LiDAR currently on the market is ToF method.

|

|

On the other hand, FMCW method is similar to ToF method in that it emits a laser beam toward the point to be measured and catches the light bounced back, but the frequency of the emitted laser beam is continuously changed. The phase of the bounced laser light then changes in accordance with the distance between the object and the object it hits and the speed of the object, so distance information from the object can be acquired together with velocity information of the object.

|

|

LiDAR scanning method

LiDAR, which operates based on these principles, utilizes various lenses and optical elements to measure a wide range of areas. In automotive applications, both mechanical rotation type and solid-state type LiDAR systems are used.

The mechanical rotation type was one of the first types to be practically used and is commonly employed in research vehicles for autonomous driving. It involves a motor that rotates a laser light source and a mirror that reflects the laser light. However, due to the motor usage, reducing power consumption, costs, and size presents challenges.

On the other hand, the solid-state type does not rely on a motor. There are different proposed methods, but they can generally be categorized as flash type and scanning type. The flash type captures and measures laser beams emitted on one surface at a time using an integrated sensor. While this method is reliable and suitable for mass production, it requires a high-intensity laser light source as the measurable distance is relatively short.

The scanning type consists of two approaches: Micro Electro Mechanical Systems (MEMS) scanning method and Optical Phased Array (OPA) scanning method. The MEMS scanning method utilizes an electrically driven microscopic mirror called a MEMS micromirror to change the direction of laser light emission and scan a wide area. The OPA scanning method controls the direction of light emission and scans the surrounding area by leveraging the diffraction and interference properties of light. Both methods offer advantages in measurement accuracy, power consumption, and mass production. However, there is a trade-off between the distance that can be measured and the frequency at which sensing data can be updated.

Needs and challenges of long-range sensing in LiDAR

|

|

What is required for long distance sensing

LiDAR for automated driving must be capable of long-range sensing. Generally, it is said that 200 m or more is required. The challenge then becomes the ability to catch the bouncing laser light. The laser light emitted from LiDAR is scattered by the surface of the object, so only a very small amount of light returns to LiDAR. If the bounced laser light is not received, the object is treated as if it had never been there. Therefore, the ability to receive the laser light reflected back at a distant point is a very important factor in the design of LiDAR.

Issue: Laser power cannot be increased for eye-safety

To achieve long-range sensing, increasing the intensity of the emitted laser light is effective. LiDAR typically utilizes an infrared laser with a wavelength of 905 nm, which is relatively safe for the human eye. However, there are limitations to increasing the output power. Furthermore, intensifying the laser light results in larger equipment, higher costs, and increased power consumption.

Enhancing the photosensitivity of the laser beam is also effective for long-range sensing, but it presents challenges in terms of requiring a high-performance photosensor, which is costly and technologically demanding. Therefore, for long-range measurement, it is crucial to minimize the amount of light scattered and lost by covers, lenses, mirror surfaces, etc., along the path of the reflected light returning to the LiDAR's light receiving element, and to efficiently collect the reflected light.

What is required of LiDAR covers and DNP's proprietary technology

Issues of LiDAR cover

The housing of an automotive LiDAR is covered to protect the sensor from flying rocks and mud splashes. Previously, the part of a LiDAR designed for long-range detection, where the light is emitted and focused, was typically made of glass, which allows laser light to pass through easily. However, glass is more expensive than resin, and the need to connect resin and glass during assembly limits productivity and design flexibility.

DNP is addressing these challenges by developing the following products.

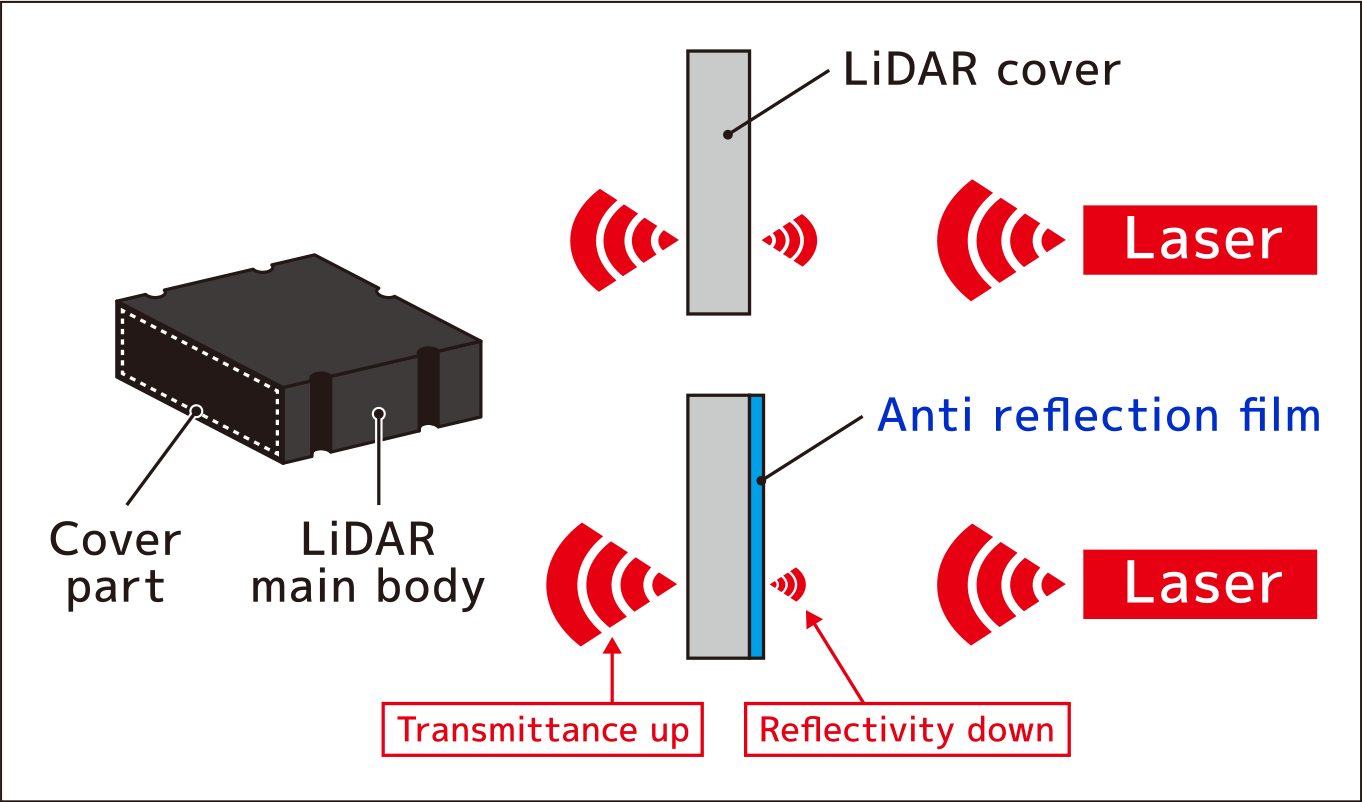

NIR-AR film *Under development

Near Infrared Rays-Anti Reflection (NIR-AR) film developed by DNP improves the transmittance of laser light by reducing the reflection of laser light on the LiDAR cover. By replacing glass with polycarbonate resin, the cover can be molded in one piece, leading to improved productivity and greater design freedom. In addition, polycarbonate is less likely to break than glass, is inexpensive, and has excellent weather resistance. It is also relatively easy to shape and process, making it possible to optimize the angle of incidence of the laser to reduce distortion caused by refraction and to easily change the design depending on the car model.

|

|

The LiDAR cover formed with anti reflection film on the inside (illustrated on the bottom) suppresses Laser light reflected on the surface of the LiDAR cover compared to the one without the film (illustrated on the top), thus improving transmittance.

Related products

In addition to NIR-AR film, DNP possesses a great deal of know-how in the design and manufacture of optical films such as Anti-Reflection film (AR film) and Anti-Glare film (AG Film) .

DNP for development and manufacture of optical films for LiDAR covers

At DNP, we possess extensive expertise in the design and manufacturing of optical films for LiDAR covers. We encourage you to reach out to us for the development and production of customized solutions that align with your specific requirements. With DNP, we can offer a diverse range of proposals to cater to your unique needs.