Heat Pipes vs. Vapor Chambers

Learn differences in performance and applications between Vapor Chambers and heat pipes

The latest electronic devices like smartphones and tablets are small but powerful, so efficient thermal management solutions are essential. As for thermal solutions, heat pipes and Vapor Chambers might come up. These are making lots of buzz on the Internet, but do you know what the difference between them is? This article navigates you through the world of heat pipes and Vapor Chambers, digging into their details by focusing on how they work, their performance, and their applications.

INDEX

What are heat pipes and Vapor Chambers?

Both heat pipes and Vapor Chambers are two-phase devices used as thermal management solutions. A heat pipe is a device with high thermal conductance that can transport large amounts of heat with a slight temperature difference between its hot and cold ends. On the other hand, a Vapor Chamber is composed of flat heat pipes with very high thermal conductance, having flat surfaces on the top and bottom sides. When compared to traditional solutions like copper heat spreaders, heat pipes and Vapor Chambers have many strengths. First, they have a higher thermal conductivity. Second, the density of the heat pipe and Vapor Chamber is much lower than that of copper. Because of its hollow structure, the heat spreaders made by Vapor Chambers are much lighter than those made of copper. These properties make them stand out as ideal thermal management solutions.

How each device works

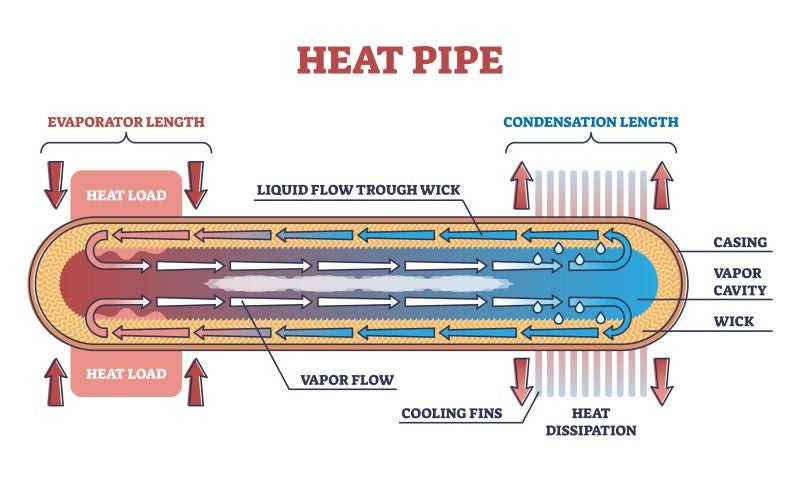

A heat pipe, consisting of a working fluid, a wick structure, and an envelope, absorbs heat from its one end installed to the heat source when the working fluid evaporates as latent heat. The working fluid that has moved to the low-temperature section condenses and returns to liquid while releasing heat. The working fluid that is now liquid then returns toward the heat source due to capillary action.

When it comes to the structure, a heat pipe is made of metal with high thermal conductance containing a small amount of working fluid, like pure water, sealed. The pipe is altered to have a wick and uses a combination of evaporation and condensation of this working fluid to transfer heat efficiently. It transfers heat quickly and continuously without power. While heat pipes are made from a wide range of materials, copper is often used because of its high conductance. Many fluids can be used though, de-ionized water is often the choice as the working fluid due to its high latent heat, surface tension, thermal conductivity, and boiling temperature. The internal wick can vary depending on the application and orientation of the cooling device.

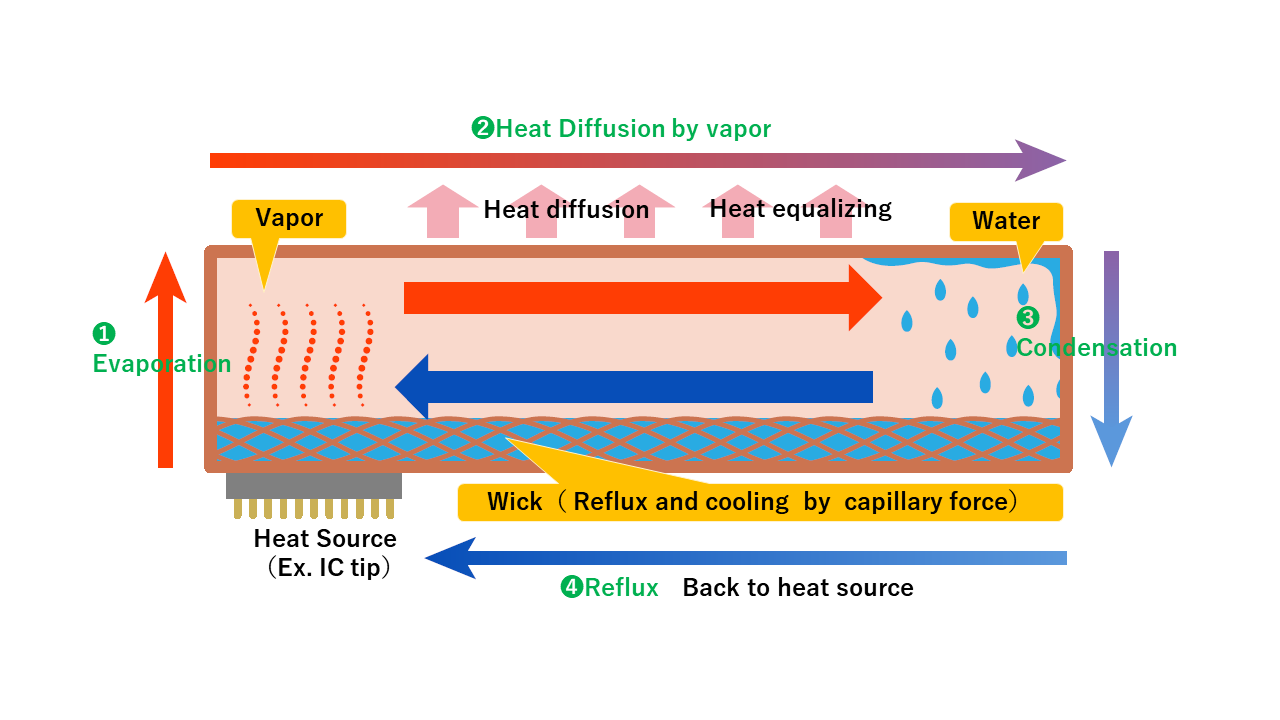

A Vapor Chamber actually operates by the same principles as heat pipes. It has a metal enclosure that is vacuum sealed, an internal wick structure installed inside, and a working fluid that moves within the system thanks to capillary action. In detail, the heat source makes direct contact with a portion of the Vapor Chamber and a finned heat sink attached to the top. Some of the working fluid vaporizes and flows to cooler areas. Heat absorption causes the vapor to condense and return to liquid which is reabsorbed by the wick structure and distributed to the heat source.

As for the most common configuration, a Vapor Chamber houses vapor within a chamber instead of a pipe, and that’s why it is called a Vapor Chamber. The Vapor Chamber is a planar heat pipe, which can spread heat in two dimensions, using its entire body to cool the heat source. Its flat structure allows heat to be transferred evenly through a very small space. You can imagine a Vapor Chamber as a flat heat pipe in such a sense. Vapor Chambers are usually composed of thin plates having precisely formed grooves and a wick structure sealed together. They are also filled with a small amount of fluid, such as de-ionized water, just like heat pipes, which allow heat to be dispersed away from the source. The cooling efficiency of heat pipes is reduced when the pipes are bent or thinned because of its structure. But Vapor Chambers can be thinned to 0.25 – 0.2 mm thick.

How each device is different in performance

The table below shows the advantages and disadvantages of heat pipes and Vapor Chambers.

Heat pipe

Strengths:

•Has an extremely high conductance

•Flexible in design

Drawbacks:

•Requires a certain thickness due to the structure

•The heat transfer efficiency is reduced when a heat source is high

•The structure with pipes is not suitable for thermal diffusion of a large area

Vapor Chamber

Strengths:

•Has an extremely high conductance

•Capable of transferring a large amount of heat

•Unit can be made very thin

•The heat transfer can stay efficient even when a heat source is high

•The planate structure is capable of diffusing heat instantaneously, even for a large area

Drawbacks:

•Tends to be high-priced than other heat sink devices

•Design is limited to the plane shape

Both devices have excellent heat transport efficiency for dissipating heat. While heat pipes remove heat from the heat source, Vapor Chambers spread heat. The use of these devices should depend on the application, but both heat pipes and Vapor Chambers do a great heat transport job.

What about heat-carrying capacity? A single Vapor Chamber designed for cooling electronic devices can manage power input up to 450 watts, whereas the largest heat pipe that is commercially available tops out at around 125 watts when used horizontally. From the perspective of heat-carrying capacity, we can say that Vapor Chambers are advantageous.

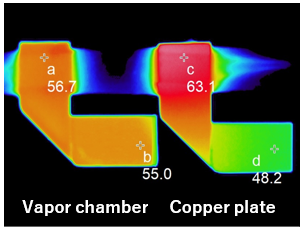

Isothermality is another comparison factor. There are commonly two ways in which thermal management devices are implemented to improve isothermality. The first is the indirect interface, where a base plate that is mounted to the heat source conducts heat to embedded heat pipes. The second is the direct interface, where the heat pipes are mounted directly on the heat source. The direct interface method is more expensive but performs better. Thanks to their large internal cross-sectional area when compared to heat pipes, Vapor Chambers can connect multiple heat sources on the same heat sink. Vapor Chambers minimize temperature differences between and around heat sources and are more isothermal than heat pipes.

Heat Pipes vs. Vapor Chambers: Practical Comparisons

Let’s dig a little bit deeper. The following section compares their design flexibility, size difference, and cost.

Design flexibility

As for heat pipes, you can bend pipes and install them in all directions. This provides heat pipes with design flexibility and enables them to be used alone, in combination, and in different positions. Heat pipes are necessary especially when heat management is challenging due to complicated paths from the heat source.

The design flexibility for Vapor Chambers is limited to the plane shape. They are flat with their two stamped plates, so the design is limited to contiguous shapes along the flat outer layer axes. Some recent Vapor Chambers come with design flexibility, where they can be bent into L or U-shape. But so far, heat pipes are advantageous in design flexibility by a mere touch.

Size

When it comes to physical dimensions, heat pipes maintain a width-to-height aspect ratio of about 4:1 or less for smaller diameters, even though they are flattened to their limit. For example, when an 8-mm heat pipe is flattened to 11 mm wide, the entire unit will reach 2.5 mm high. The use of mesh wick can achieve more flattening. On the other hand, a 2.5-mm-thick Vapor Chamber can be widened to about 150 mm, making the width-to-height aspect ratio 60:1.

Cost

In many cases, a single heat pipe was enough, and this simplicity contributed to improving the manufacturing process of heat pipes and brought a price down. On the other hand, the manufacturing process of Vapor Chambers, where two copper plates are pressed and sealed, is more costly. But the appearance and rise in demand for one-piece Vapor Chambers have got pricing closer to the design of a heat pipe with multiple pipes. But the winner in cost should be heat pipes.

Heat Pipes vs. Vapor Chambers: Applications

Heat pipes and Vapor Chambers can be used for various applications. These days microprocessors have shrunk, and this fact has resulted in ever-increasing power density producing heat that needs to be dispersed quickly. Technically, heat pipes are typically used for applications with a power density of less than 25 W/cm2, while Vapor Chambers are certainty used when the density approaches 50 W/cm2. Let’s take a look at the strong suits of both devices.

Strong suit of heat pipes

Cooling applications with heat pipes cover various fields, from space to medical devices and power electronics cooling. Recent reduction in size of heat pipes has enabled them to be used for CPU cooling for personal computers, smartphones, and tablets. Heat pipes can be easily bent and flattened to wrap around crowded system components, making them the reliable choice when heat needs to be moved from the heat source to a remote fin stack normally more than a distance 40 to 50 mm away.

Strong suit of Vapor Chambers

Vapor Chambers spread heat, so they are often used to spread heat to a local heat sink. Taking advantage of their large continuous areas, they can achieve better isothermalization. Vapor Chambers must serve as a great solution, especially when a heat sink that is minimally ten times, but usually closer to twenty times, the area of the heat source. Additionally, heat sources with high power densities or limited airflow to cool them often require a heat sink base material that is more thermally conductive. Such a situation is also where Vapor Chambers can be actively used.

Heat Pipes vs. Vapor Chambers: Which should we use?

Both heat pipes and Vapor Chambers are excellent thermal management solutions. But their performance will be affected depending on the application. Here are two applications as examples. Which solution, heat pipes or Vapor Chambers, should be used?

Wearable devices

New portable, worn, and mobile devices have become powerful but at the same time require lower touch temperatures for safety. These include gaming consoles, AR devices, and portable medical devices. They are not free from thermal management. Heat must be transferred and dissipated quickly to maintain their performance and safety. But this is a challenging task, especially in a powerful and compact package that needs to be mobile or portable. Thermal management solutions should also be smaller, compact, and thin. For these reasons, thin Vapor Chambers can serve as the best option for thermal management in smaller applications. Vapor Chambers are especially effective because they are flat, have one plane, and X-Y spreading. So, spreading the heat from single or multiple chips over an increased surface area of Vapor Chambers creates a more uniform heat transfer and improves cooling. Vapor Chambers are the best solution for heat dissipation for wearable devices.

Mobility products

Mobility products take a wide variety of forms depending on their applications. Thermal management is also the key for mobility products, just like wearables and portable devices. Active air cooling or liquid cooling alone are often too large and cumbersome. Other factors to consider also include acoustics, weight, and vibration. Vapor Chambers can also be a powerful solution, while ultra-thin heat pipes could also be an option. In addition, the design flexibility of heat pipes could fit some particular applications. The point is to understand and take advantage of the strengths and characteristics of each thermal management solution to make the best fit for each application.

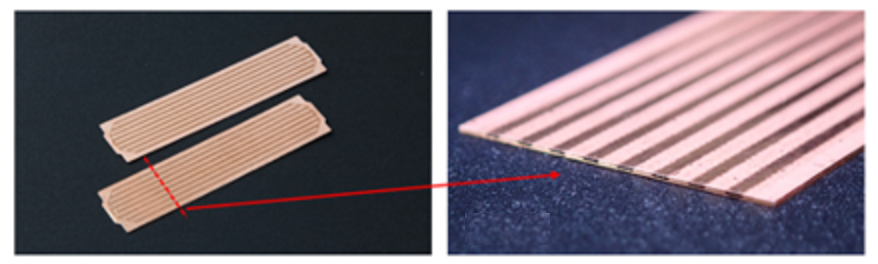

DNP’s High-Performance Vapor Chambers

Foreseeing that continuous need for downsizing and technical advancement of electronic devices would create the demand for heat dissipation, DNP entered into the heat sink component market. DNP has developed 0.2-mm-thick, thin Vapor Chambers by taking full advantage of its ultrafine processing technology based on chemical etching at the level of ten micrometers. These thin Vapor Chambers have thin copper plates with fine flow paths through which the working fluid flows using a capillary structure. DNP’s Vapor Chambers are highly conductive, thin, and light, but flexible in order to fit complicated platforms with curved planes and multiple levels. Thanks to such fantastic flexibility, their design can adapt to a wide variety of forms and shapes that the conventional Vapor Chambers have never been able to achieve. Manufacturing such attractive Vapor Chambers is brought about by DNP’s high-definition patterning technology including chemical etching which has become a significant strength in producing thin Vapor Chambers.