Thermoelectric Cooler Module

Learn more about thermoelectric cooler modules in this article.

This article will answer the following questions

・What are the most common situations in which the thermoelectric cooler modules are used?

・What are the characteristics of the thermoelectric cooler modules cooling method?

・What are the advantages of thermoelectric cooler modules compared to other cooling methods?

Enjoy the profound world of thermoelectric cooler modules.

INDEX

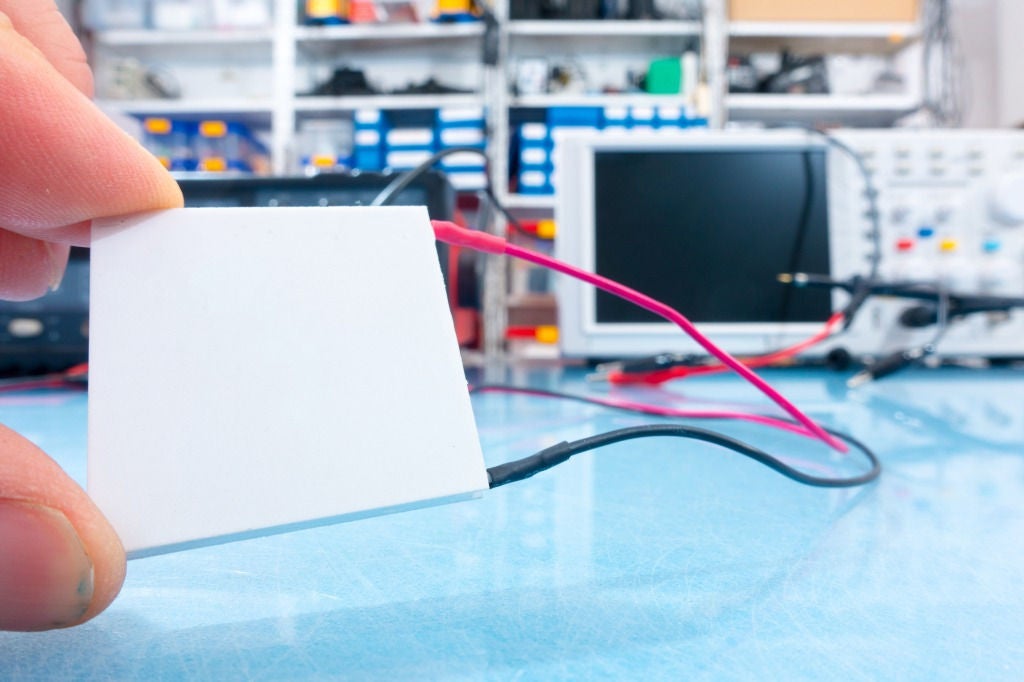

What is a thermoelectric cooler module?

A thermoelectric cooler module is a device that transfers heat from one side of a material to another. This type of cooling system uses the Peltier effect to cool or heat a space. The Peltier effect is named for Jean Charles Athanase Peltier, who discovered it in 1834.

In simple terms, the Peltier effect is an electrical current that flows through an electrically conductive material when one side is heated and the other side cooled. A thermoelectric cooler module uses this phenomenon to transfer heat from one side to another, which can then be used to cool or heat a space.

Where are thermoelectric cooler modules used?

Peltier devices go by a number of names, including "Peltier heat pumps," "solid-state refrigerators," "thermoelectric cooler modules (referred to as TEC modules in this article),” and "thermoelectric batteries." These devices are all the same and though they are most often used for cooling, they can on occasion be used for heating.

What are the types of thermoelectric cooler modules?

TEC modules are ideal for applications where there’s no access to water or cooling oil (such as in space). They’re also energy efficient, highly portable, and easy to use—all qualities that make them well suited for industrial processes and other commercial uses.

Furthermore, TEC modules are used in many ways and are very common in electronics, especially computers. They're also used in things like medical equipment, air conditioners, and even spacecraft. A very common place you'll find them is in portable wine refrigerators; sometimes people call them "Peltier chillers."

Advantages of thermoelectric cooler modules

TEC modules are a great way to keep a system running efficiently and cool. It can also save money by reducing the amount of energy needed for cooling a given space. Here are some of advantages of TEC modules:

1. They allow for greater efficiency than traditional air conditioning systems because they use less power and have fewer moving parts, which means less wear and tear occurs on the system over time.

2. TEC modules are quieter than conventional fans. This is because they do not contain moving parts and therefore do not generate vibration or noise.

3. The cost of installing this type of system is much lower than what it costs to install a fan unit inside an office building. Thus, the initial investment cost to purchase TEC modules can be kept low.

Restrictions of thermoelectric cooler modules

The first restriction of TEC modules is that they require a massive amount of energy in order to produce any significant amount of power. While this is not necessarily an issue for small devices, it becomes problematic when a great deal of power is needed for large devices or buildings.

Another restriction is that since only one temperature difference is created by TEC modules, they can’t be used with multiple objects at different temperatures at once (unless they are very close together). This means that if you wanted to use them for both your car engine and refrigerator at the same time, then each item would need its own separate module instead of just sharing one module with multiple ports like most other types of cooling systems.

They can also be expensive. You'll need to pay for installation as well as the cost of the unit itself.

The structure of thermoelectric cooler modules

A TEC module is a device that converts heat into electricity. The cooler module has a layered structure, with the inner layer being made of metal and the outer layer being made of plastic. The metal layer is heated by the heat source, and the plastic layer is cooled by a cooling medium (such as water). When a temperature difference between these two layers exists, electrons flow from one layer to the other. This allows for electricity to be produced, which can then be used for various purposes.

Comparison with other cooling methods

Plate heat exchanges

Plate heat exchanges are a great option for cooling large spaces, and they come in many sizes. The larger the plate heat exchanger, the more it can cool.

TEC modules are also an excellent choice for cooling large areas and they have some distinct advantages over a plate heat exchange system. TEC modules are more compact, which means they take up less space and are easier to install than other types of cooling systems, making them ideal for retrofits or new construction projects where space is limited.

Because they're compact, they're also much easier to service than other types of systems like refrigeration units or air conditioning units, which require special training.

Heat radiators

Heat radiators are the most common way to cool a home but they have some downsides. For example, if you live in a place that gets very cold in winter, heat radiators just don't cut it. They don't work well when temperatures are below freezing because they need heat to transfer from the radiator into the air of your home.

They also waste a lot of energy: only about 15% of the energy used by heat radiators goes into heating the water in the radiators; the rest is wasted as heat that escapes into the air around your home.

TEC modules are a newer technology that uses electricity to create a cooling effect on one side of its metal plates while heating on the other side. This means that thermoelectric modules can be used at any time of year; they work just as well whether temperatures inside or outside your house are high or low.

Thermal grease

Although thermal grease and TEC modules share some applications, other applications where one or the other would be better suited exist. A small device may use thermal grease to effectively transfer heat by connecting the heat source and a heat sink or other device with low contact resistance, but the whole device won’t necessarily be cooled; thus, thermal grease comes in handy because it only works on surfaces in direct contact with each other.

However, if you need your device to run at maximum performance or constantly overclock itself and keep its temperature under control, then you'll need a TEC module.

Heat dissipation

When it comes to choosing a heat dissipation system, you have a lot of options. You can choose between heat dissipation systems that use air or water, for example, and you can also choose between a variety of fans and pumps. However, when it comes to choosing between a TEC module and a heat dissipation module, there’s no question—the TEC module is the way to go.

TEC modules are more efficient than heat dissipation modules because they only use one-third as much energy while providing twice as much cooling power. They also tend to be smaller than heat dissipation modules and require less maintenance since they don’t have moving parts.

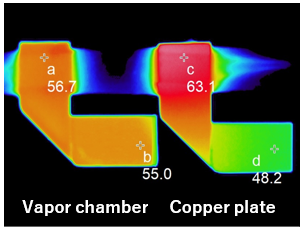

Vapor Chambers

Vapor Chambers are made primarily of a wick, an enclosure, and liquid that absorbs heat from the source through the wick. Some types of Vapor Chambers also include a heat spreader on top to conduct heat away from the source.

Both Vapor Chambers and TEC modules are used in electronics to cool them, but there are some differences.

The main difference is that a Vapor Chamber requires liquid refrigerant or coolant while thermoelectric coolers use solid-state thermoelectric materials.

Although neither TEC modules nor Vapor Chambers have moving parts, Vapor Chambers had the added advantage of being able to achieve uniform temperatures across the surface.

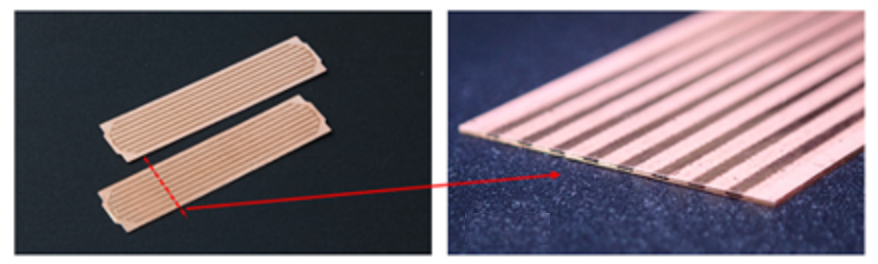

DNP's Vapor Chambers

As the world moves towards adopting 5G networks, the increased data processing will require thermal management solutions for high capacity application processors and integrated circuits. Current technological limitations mean that existing TEC materials are too thick to be used in thin devices.

When 5G compatible devices become more widely available, a solution will need to be created to protect these next generation electronics.

In order to keep up with these ever changing times, DNP has developed Vapor Chambers for use in 5G communication devices. The thin Vapor Chambers are thinner, more flexible, and it’s being heralded as a way to help dissipate heat in the next generation of electronics.

This is an extremely important development, which will pave the way into the future. (* Information as of February 2022)