DNP and Yokohama National University Develop Hydrogen Detection System Using RFID

No heat generated by catalytic combustion gas sensors

Tokyo, February 25, 2025, Dai Nippon Printing Co., Ltd. (DNP) in collaboration with Yokohama National University has developed a Hydrogen Detection System that detects hydrogen leaks by combining a hydrogen detection film, whose electrical resistance changes when it reacts with hydrogen, with a Radio Frequency Identification (RFID) IC tag1.

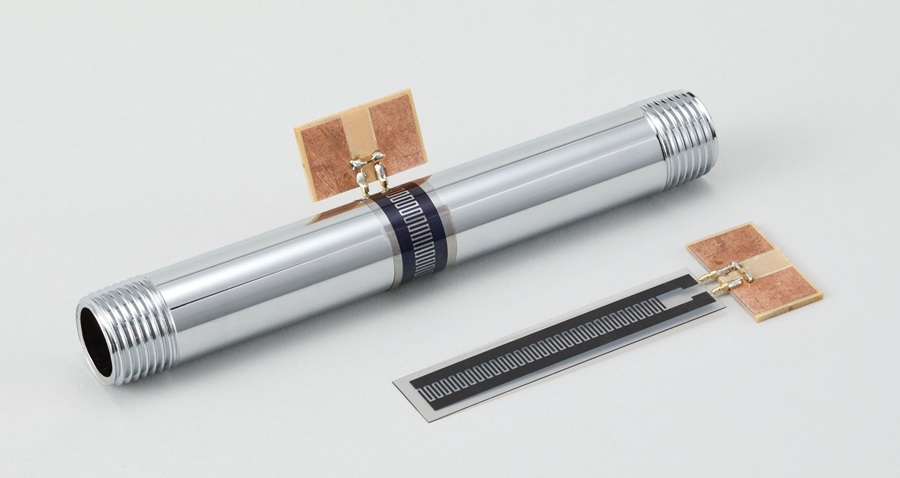

The newly developed system consists of a transceiving antenna and a hydrogen detection sensor, which is attached to components where hydrogen is likely to leak, such as pipe joints at hydrogen production plants and stations. When reacting with hydrogen the electrical resistance changes inside the sensor, and this change is returned to the reader/writer via radio waves to detect hydrogen leaks. Also, as the sensor does not require a power source, it can detect hydrogen leaks at an early stage while reducing the risk of ignition due to the existence of a power supply. Technology has also been established allowing the sensor to be manufactured into a film format that can be rolled so as to fit the shape of the pipe, making it suitable for flexible installation.

Image of Hydrogen Detection System Sensor

Background

Hydrogen energy has been attracting wide attention as a clean energy source that does not emit CO2 when burned. The hydrogen energy equipment and systems market size in Japan is predicted to reach 663.3 billion yen2 in FY 2030. However, hydrogen is more prone to leaking, igniting, and burning than city gas, hence, detection systems are also required in order to be able to handle hydrogen safely. Most conventional gas leak detectors use catalytic elements heated to high temperatures, which poses the risk of becoming an ignition source.

In this latest development, DNP has combined the strengths it has cultivated over many years in RFID-related businesses and the development of various systems, with the strengths of hydrogen detection materials and film formation technology created by Professor Shinji Okazaki of the Faculty of Engineering, Yokohama National University, to develop a Hydrogen Detection System that utilizes a sensor that does not require batteries nor any heating, which runs the risk of becoming an ignition source.

Hydrogen Detection System Features

1. Hydrogen Detection System based on high-level safety considerations

The newly developed Hydrogen Detection System is highly safe. It significantly reduces the risk of ignition by eliminating the need for sensor batteries, which, if used, could heat up the sensor element or generate sparks.

2. The sensor is in film form, allowing it to be installed in a variety of facilities and locations

The sensor can be manufactured into a flexible film, making it adaptable enough to be installed in a variety of locations, such as in hydrogen gas pipes and the connections of various valves. Under the newly developed system the sensor can be applied to locations that were previously difficult to address with fixed sensors. The new sensor facilitates the management of hydrogen leakage risks over a wider area. It can also be deployed in a variety of facilities and equipment, such as hydrogen production plants, hydrogen stations, and hydrogen vehicles. In addition, it is easy to install, leading to reduced implementation time and costs.

3. Multiple sensors enable leak detection and remote monitoring

The newly developed system utilizes RFID technology, which allows for simultaneous detection via multiple sensors, along with a monitoring capability from remote locations. The use of multiple sensors makes it possible to centrally manage hydrogen gas leaks within a large facility, leading to the prevention of leakage and more efficient monitoring. Also, by having the user carry a small reader/writer, leaks of colorless and odorless hydrogen can be quickly notified to on-site workers via a wireless alarm, contributing to improved safety in hydrogen-related work. Other currently employed detection methods use a film that changes color when it reacts with hydrogen, but this method requires regular visual inspection of the film. As the new Hydrogen Detection System does not require visual inspection, it helps reduce the number of people required for cumbersome inspection work.

Looking Ahead

DNP will provide the jointly developed Hydrogen Detection System utilizing RFID technology to engineering companies and related system vendors that build hydrogen production plants and hydrogen stations, as well as companies that sell hydrogen energy, aiming for cumulative sales of 3 billion yen by FY 2030. We will also continue to develop products and services that contribute to the spread of clean energy, including hydrogen, thereby contributing to the realization of a carbon-free society.

1 RFID (Radio Frequency Identification): An automatic identification technology that uses radio waves to read and write information without contact. In this latest development, a passive tag was used that is charged by power supplied from a reader/writer and which can send and receive data.

2 Source, Yano Research Institute Ltd., Survey on the Hydrogen Energy Utilization Equipment and Systems Market (2024), announced on June 10, 2024. The calculation was based on the value of new equipment and systems introduced in the fiscal year, covering power generation equipment and devices, combustion equipment and devices, and transportation equipment and devices that use hydrogen as an energy or power source.

* Company names and product names names mentioned in this news release are the registered trademarks or the trademarks of those companies.

* The contents of this news release are current as of the date of announcement. They may be changed without notice.

- Select location

-

- Category

-