DNP Uses Unique CVD Technology to Develop Transparent Film with High-Barrier Features for Industrial Uses

Dai Nippon Printing Co., Ltd. (DNP) has applied a uniquely developed ChemicalVapor Deposition (CVD1) technology in the development of a transparentfilm with high-barrier properties for industrial uses, including flexible organicphotovoltaic (PV) cells and organic EL displays.

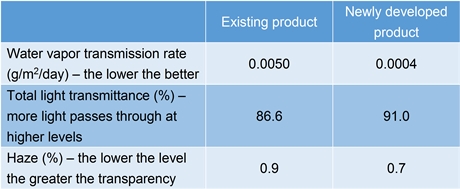

The film achieves a high-level water vapor barrier property, based on a moisturevapor transmission rate of 0.0004g per 1m2 per day. That puts thebarrier properties on the 10-4 rate, or less than a tenth of the previouslydeveloped 0.005, 10-3 rate film. In addition, the newly developed film improveson both transparency and light transmission.

[Background]

DNP commenced the mass production of transparent film with high-barrier propertiesin 1998, and has since broadly applied the film in a variety of uses, includingfood packaging and infusion solution bags.

At the same time, needs have existed for the use of such high-barrier filmin place of glass, for such industrial uses as flexible organic PV cells andorganic EL displays. To achieve this, however, requires special manufacturingdevices and technology. Other challenges also presented themselves, such ashigh costs based on low productivity due primarily to the narrow film widthwhich was only possible to produce. This time DNP has boosted productivity bycapitalizing on the mass production technology developed in the creation oftransparent barrier film, and has successfully developed a transparent filmwith high-barrier properties that maintain improved water vapor and oxygen barrierperformance, higher transparency and light transmission features.

[New Product Outline]

- The new product is equipped with high-barrier properties, includingwater vapor transmission rates less than 1/10 those of existing products.Suitable for use with products that require high-barrier properties andflexible organic PV cells and organic EL displays, where the use of glassis difficult.

- As the newly developed product is highly transparent and virtually colorless,it is suitable for optical uses, such as displays.

- Productivity has been improved, by applying existing transparent barrierfilm manufacturing facilities and mass production technologies.

[Looking Ahead]

DNP has positioned Knowledge and Communication, Food and Healthcare, Lifestyleand Mobility, and the Environment and Energy as business growth areas, and is engagedin the creation of new values. The Company aims for sales of 15.0 billion yenper year in 2020 by focusing on the sales promotion of transparent film withhigh-barrier properties for industrial use.

* Chemical Vapor Deposition : A thin film coating technology. A chemicalreaction is initiated, under vacuum conditions, in the gas that is the raw materialof the film, and a thin coating formed on the surface of the film. Thin filmmanufactured under CVD exhibits few signs of deterioration due to stretchingor bending. DNP led the world in adopting this technology for food packaginguses.

* Product prices, specification and service contents mentioned in this newsrelease are current as of the date of publication. They may be changed at anytime without notice.

- Select location

-

- Category

-