DNP Develops Crack Detection System of Deteriorating Concrete Structures Including Tunnels

Employs sheet-based RFID IC tag and accurately detects crack expansion

Dai Nippon Printing Co., Ltd. (DNP) has developed a testing system to detectspread in decrepit concrete cracking in tunnels, bridges and others.

[Developmental Background]

Much of Japan's social infrastructure-related construction, including tunnelsand bridges, was performed during the period of high economic growth; from approximately1954 to 1973. In recent years, however, these structures have been allowed toage, and cracked and falling concrete has become a social problem. Local authoritiesand operators are legally obligated to perform periodic checks, but at the sametime, this requires skilled workers using expensive equipment in order to ascertainthe status of the underlying concrete. And the resultant costs and lack of adequatelytrained personnel have become a challenge. In order to overcome this challenge,DNP has developed a film sheet format testing system based on a Radio FrequencyIdentifier (RFID) IC tag that detects spread in concrete cracking in asimple manner,

[System Features]

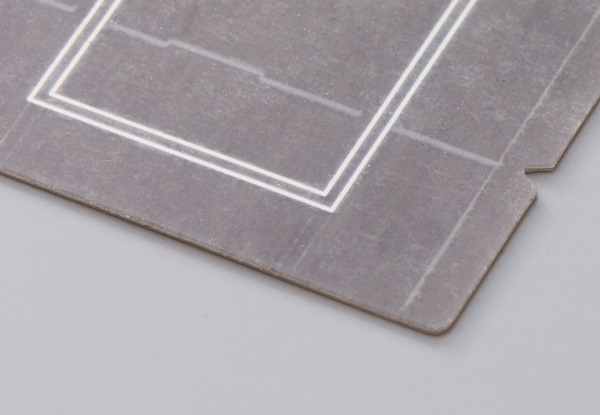

The newly developed system employs a testing sheet with a built-in passiveIC tag that is activated by external radio waves. The sheet is applied to spotswhere micro-cracks have emerged on the surface of the concrete, and which aredeemed likely to reduce the functionality of the structure at some point inthe future, and therefore, require monitoring. By way of example, accordingto periodic testing guidelines for cracking in road tunnels laid down by theMinistry of Land, Infrastructure, Transport and Tourism, if cracking expandsby in excess of 3mm then early repairs are needed.

The newly developed sheet detects the progress of cracking via break in thepattern circuit.

The features of the newly developed sheet are as follows;

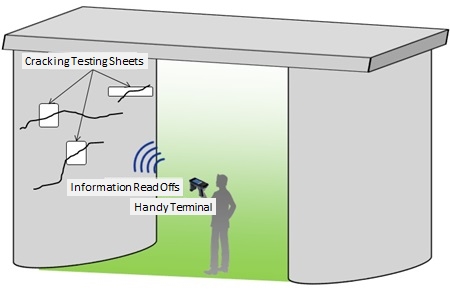

- A dedicated UHF band-responsive reader-writer is capable of readingoff information from multiple sheets collectively, facilitating inspectionwork efficiencies.

- The crack detection sheet is not battery-driven, and therefore requiresno exchange of batteries. And as the sheet uses a long distance UHF bandIC tag, it is possible to perform read-offs at a distance of several meters.

- As it is possible to perform read-offs for cracking in a simple mannereven in locations that are difficult to confirm by sight, oversights andomissions can be avoided. Cracking of even just several millimeters canbe detected by waving the reader-writer over the spot in question. No specialskill is required, and workers can accurately perform the required testing.Data obtained by the reader-writer can be transferred to a computer allowingfor the creation of testing logs in a simple manner

- The cracking testing sheet also employs a unique adhesive material,also developed by DNP, which hardens when exposed to ultraviolet light fromthe sun or fluorescent lighting.

[Looking Ahead]

DNP will conduct field tests and marketing using the newly developed system,aiming for commercialization in spring 2018.

* Product prices, specification and service contents mentioned in this newsrelease are current as of the date of publication. They may be changed at anytime without notice.

- Select location

-

- Category

-