DNP Develops New Retortable Film Allowing for Clearer Laser Printing

Securing food safety by preventing falsification of best-by dates and others

Dai Nippon Printing Co., Ltd. (DNP) has developed a new film that allows for clear displays of printed text and numbers on it with lower levels of laser application and that can also be used under retort sterilization conditions.

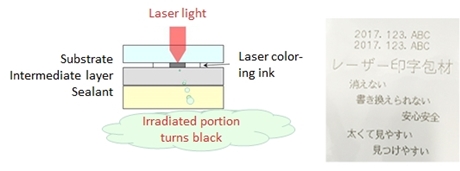

At left: Coloring mechanism / At right: Printed sample

Development and Product Summary

In May 2015, DNP developed a low cost laser-printable packaging material with increased visibility for the display of best-by dates and other information on foods, which has since been adopted in a number of processed foods. This packaging material uses an originally developed DNP ink that is coated on the interior of the film, and which changes color from white to black when exposed to laser light.

In this latest development, the Company has pursued a number of improvements, including devising a way to blend white ink with color producing ink, to make it possible for printed text and numbers to be clearly visible using approximately half the volume of laser lighting compared to currently available techniques. As a result, it has been possible to significantly boost the visibility of the text and numbers. And by cutting the volume of lasers used it has also become possible to reduce packaging damage.

Features

As the printing method involves coating laser coloring ink between multiple film layers it is possible to prevent best by dates and product information from being erased due to contact with other objects, or staining with oil etc., thus making the new format effective in the prevention of tampering or fraud.

As it is possible to display text with thicker font lines than previously available, visibility is increased.

As this can be achieved with lower volumes of used lasers, it is also possible to reduce damage to the packaging materials.

As a result of ink cost reductions, it is also possible to reduce unit printing costs. For example, in the case of a 150,000 bag production lot it is possible to reduce laser printing unit costs to no more than 20% of those with currently available methods.

Compared to ink jet, thermal transfer and existing carbon dioxide laser printing formats, it is possible to reduce ink waste and smoke emissions, facilitating manufacturing in a clear environment.

Also, compared to ink jet and thermal transfer printing formats, there is no need for ink or ink ribbon components, which helps reduce overall print processing costs.

Print density will not dilute even under hot water immersion retort of 30 minutes at 121°C, facilitating good visibility.

Forward Looking Developments

DNP will market the newly developed product for use with foods, pharmaceuticals and daily necessities, aiming for sales of 1.0 billion yen in FY 2020.

1: For further information please visit:

https://www.global.dnp/news/detail/20166991_4126.html

* Product prices, specification and service contents mentioned in this news release are current as of the date of publication. They may be changed at any time without notice.

- Select location

-

- Category

-