DNP Develops Volume Production Technology of Nanoimprint-based Optical Elements Enabling Miniaturization, Low Profile and High Performance

Applications with tablet terminals incorporating vein authentication functions

Dai Nippon Printing Co., Ltd. (DNP) has developed a technology for the volume production of optical elements capable of shaping irradiated light, such as infrared light, through a micro embossed structure based on nanoimprint lithography (NIL) technology.

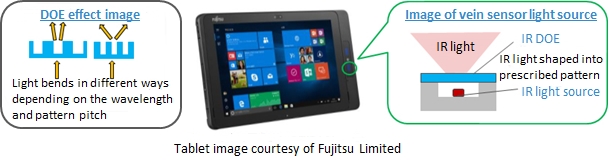

Due to their characteristics of miniaturization, the newly developed optical elements have been adopted for ARROWS Tab Q507/P-SP produced by Fujitsu Limited, a tablet terminal incorporating a slide-style vein authentication function.

NIL technology is a microfabrication technology designed to press a template mold against a resin coated substrate by transferring patterns with line width of nanometer (10-9 meter) to micro-meter (10-6 meter) level in a stable manner.

[Summary]

Demand for more sophisticated sensing is on the rise in line with increased security needs on the back of the spread of network services, the penetration of the Internet of Things (IoT), and advances in automation. In particular, infrared-driven sensing, which is a long wavelength light invisible to the eye, is broadly used, and needs exist for increased efficiency and performance along with device miniaturization through the irradiation of infrared light in specific forms and patterns.

Diffractive Optical Element (DOE) technology is one method to shape such light, and by applying this technology it is possible to design and modify the direction, strength and patterns of irradiated light.

In this latest development, through the use of optical elements produced in volume using NIL technology, DNP looks forward to increased performance, efficiency improvements and further miniaturization for various optical sensing devices and lighting apparatus.

[Detailed Development]

In order to control the infrared light used in vein authentication, it is necessary to prepare deeply embossed optical elements. And in order to shape the light and boost efficiency, it may also be necessary to narrow the pitch of the emboss pattern, and fabricate the emboss pattern into a tiered format. It is also highly difficult to create such deep and narrowly pitched emboss patterns in multi-stages, making it necessary to employ mold processing and high level NIL technology in volume production. By overcoming these challenges, DNP has made it possible to engage in the volume production of optical elements that can be incorporated into slide-style vein authentication functionality developed by Fujitsu Limited and Fujitsu Laboratories Ltd.

DNP has developed and maintains NIL basic technologies, and is in a position to optimally plan and design each manufacturing process, from mold processing, through NIL and materials design. Also, in the new development of DOE, it is also necessary for DNP to hold, on an in-house basis, the optical design technology necessary to respond to a variety of light irradiation patterns designated by the client. By combining NIL technology with optical design technology, it is possible to match the required characteristics in the optimum manner, and to design and manufacture DOE that corresponds to various light sources, such as laser light sources and LED.

[Future Developments and Anticipated Applications]

Apart from making it possible to distribute specific light wavelengths in prescribed shapes and dispositions, as the diffraction pattern layers are only several microns in thickness, it is also possible to create small, low profile optical elements. These features contribute to increased light irradiation efficiency, high precision sensing and the miniaturization of the irradiating light source.

Anticipated DOE applications include the following;

- Biometric authentication, including iris recognition

- Infrared 3D sensors for detecting peripheral 3D objects and obstacles

- Gesture sensors used as input devices for automobiles and domestic electrics

- Information and message projection devices sensing user’s surroundings.

[Looking Ahead]

DNP will focus on the use of NIL technology in the business development of the sensing zone viewed as essential to IoT and automation, aiming for annual sales of 8.0 billion yen in FY 2021 from DNP Nanoimprint Solution related products.

* Product prices, specification and service contents mentioned in this news release are current as of the date of publication. They may be changed at any time without notice.

- Select location

-

- Category

-