DNP Develops High-Precision Position Detection Marker

Automates Logistics Operations for Smart Factories

Dai Nippon Printing Co., Ltd. (DNP) has developed a marker capable of sensing with an accuracy of ± 1 degree or less, driven by image processing software and a camera to control the movements of automated transport robots used in logistics operations with high accuracy.

Background and Summary

With the start of 5th generation (5G) mobile communication system, we are seeing increased interest in smart factories that execute total control over a variety of devices and equipment via the Internet. In the field of logistics, unmanned forklifts, and other automated guided vehicles are attracting attention as important elements of the smart factory concept in response to the recent talent shortage.

To date, when a forklift driver lifted a load onto a truck, the angle of the claws has been fine-tuned so as to be maintained within ± 1 degree based on the detailed work environment, including weight, size, and the tilt of the load.

An automated transportation robot reads-off a marker attached to a package, confirms the position of the package, then reads-off a marker attached to a pillar in the warehouse, for example, to check its own position. With existing paper markers, however, it is difficult for the transportation robot to finely adjust the forklift claws in line with the tilt of the luggage due to the contraction of the paper, the unevenness of the printing, and low positional accuracy. An additional challenge is the tendency for paper to become stained or dirty, which has led to demands for a high-precision, durable, and inexpensive marker.

High-precision markers have been developed by the National Institute of Advanced Industrial Science and Technology (AIST) and are also used to measure the behavior of satellites in outer space. Also, positioning with an error of less than 10 cm has been achieved in locations where GPS does not work.

In this latest development, DNP has overcome existing challenges to develop an inexpensive marker while maintaining position detection precision. The marker is based on a new design by LEAG Solutions Corporation, which is a technology transfer venture of AIST. The newly developed marker is among the high-precision printing technologies developed over a period of many years by DNP. It utilizes the photolithography technology that has a proven track record in color filters for liquid crystal displays, and has been precision configured to measure ± several μ (10-6) m on a glass substrate.

Features

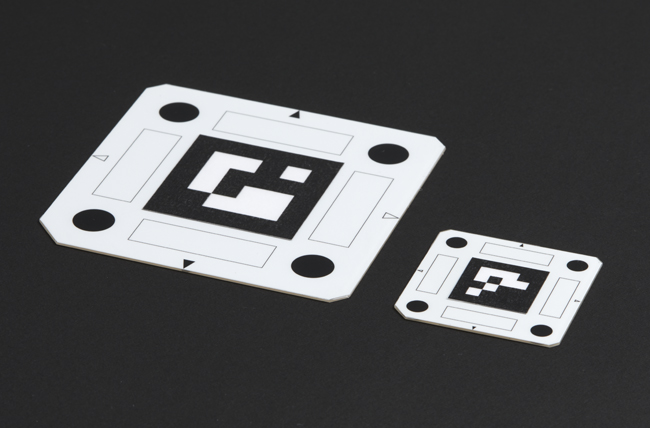

The high-precision marker developed by DNP this time is a glass substrate with a thickness of 0.7 mm and an outer dimensions of 40 mm and 80 mm per side. It can be used to identify the locations of, for example, pallets, warehouse shelves, building doors and corner pillars, along with departure and arrival points. It can be mounted on an unmanned vehicle, such as an automated transportation robot or drone, making it possible to detect position with high precision, by reading-off markers using a camera mounted on the body of a building or the unmanned vehicle. In addition, the marker is also embedded with ID data that makes it possible to identify the marker’s location along with that of the unmanned vehicle. As this information can be read-off by a camera and dedicated software, it becomes possible to convert the movements of entities into data at low cost then manage and analyze that data.

Forward Looking Developments

Looking ahead, DNP will collaborate with logistics equipment manufacturers to verify an automatic transportation system that use high-precision markers. In addition, we will provide those markers to various companies, including logistics and/or manufacturing facilities that are looking to run automatic transportation with an inexpensive system, for use with automatic transportation equipment for health care and nursing, agriculture and surveying, robots, drones, and other unmanned vehicles. We aim to achieve annual sales of 1 billion yen in FY2025.

DNP leverages the strengths of printing technology and information processing to combine 5G electronic components such as Transparent Antenna Film and the heat dissipation component Vapor Chamber, with a platform that enhances information security of the Internet of Things (IoT) to provide solutions that support the comfortable information society realized by 5G. We will also provide smart factories with the high-precision marker developed on this occasion, and the regional 5G subscriber identification module (SIM) card compatible with the creation of unique regional 5G networks.

*Company names, products and service names appearing in this release are the trademarks or registered trademarks of those companies.

*Product information and service details described in this release are accurate as of the date of issue. They are subject to change without notice.

- Select location

-

- Category

-