Masanao Matsuoka, an engineer at Dai Nippon Printing Co., Ltd., is developing a resin glass that will make electric vehicles (EVs) lighter and more durable, as automakers fiercely compete for a solid foothold in the environment-friendly car market expected to grow quickly from around 2025.

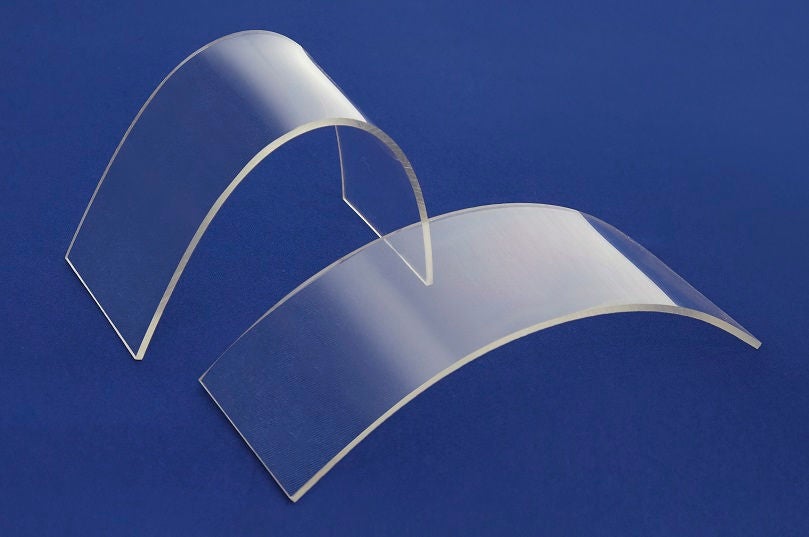

Curved resin glass showing with a 30mm diameter arc in the lower part of the image

Curved resin glass showing with a 30mm diameter arc in the lower part of the image

“Making a one-ton vehicle 100 kilograms lighter will enable it to travel an extra one kilometer per liter of gas and emit over 10 percent less carbon dioxide,” Matsuoka said in explaining the significance of developing resin glass for state-of-the-art vehicles.

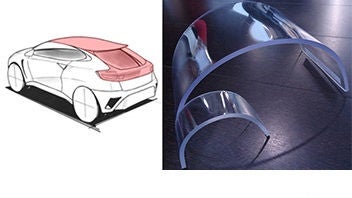

Indeed, carmakers use plastics for EV window materials and to clear increasingly stringent environmental regulations being imposed in countries across the globe. Plastic windows are 50 percent lighter than glass ones and are easier to process into different shapes, but they are unable to withstand abrasion or ultraviolet light for an extended period like glass can. It is, therefore, crucial to develop a hard coat that gives plastic windows the level of hardness, durability and resistance to weather, solvents and stains that glass offers.

In January 2018, after years of research and development by Matsuoka's team, DNP introduced resin glass that can be curved to produce an arc with a minimum radius of 30 millimeters for uses such as stylish sunroof windows and rear windshields.

A hard coat transfer film based on DNP's functional film technologies is used in the resin glass in addition to its electron beam (EB) technology, which has been used for DNP's wall and flooring materials to cure the coating. EB technology allows the production of film with a tightly cured coating through three-dimensional cross-linking of molecules and makes it easier to widen the scope of material designing because it does not require any curing material.

“Our coating technology is one of a kind for the use with automotive windows (as of September 2018). We transfer film to apply a hard coat on resin and form the resin into different shapes at once,” Matsuoka said, stressing the difference with conventional methods that coat the outermost layers by dipping or spraying only after the product's shape has been formed. Coating after the shape formation would necessitate larger equipment – a headache for manufacturers. Furthermore, a complicated work is required in the conventional double-dipping-and-double-baking method, in which shaped resin is dipped in an anchor material and baked for drying before being dipped in silica again and baked.

Breaking the trade-off between hardness and bendability

Using organic materials, such as acrylic resin, for the hard coat transfer film provides bendability. The use of silica and other inorganic materials for a hard coat, on the other hand, makes bending the resin difficult – most attempts end up breaking.

To harness these advantages, however, Matsuoka's team had to break a trade-off for using organic materials. “If we pursue the hardness of inorganic materials like glass, it becomes difficult to bend,” Matsuoka said. “For the resin to bend, the hard coat has to have a high formability.”

The answer to this quandary was to have good materials design, which Matsuoka's team at the Mobility Operations department is still trying to improve.

“DNP is a printing company that has handled organic materials, so we should capitalize on our experience to differentiate ourselves” from rivals, Matsuoka explained. “Organic materials are superior in many ways, so we want to research them further.”

Novice in handling organic materials for hard coats

Matsuoka was assigned to lead a team tasked with developing a hard coat transfer film for construction machine windows in October 2014. A physicist by training, he had only limited knowledge about the organic chemistry that was required for his job at the time. Nonetheless, Matsuoka effectively cleared the few remaining stumbling blocks in materials design before introducing the product to the market. This reinforced his reputation as a “trouble shooter.”

Matsuoka's most difficult task was a problem inherent to a transfer film. When making a transfer film, the process must be considered in reverse because the film's bottom layer will become the top layer when adhered to resin glass. Resin ingredients that provide needed functions such as hardness, weather-resistance and durability tend to float to the upper part of coating on the substrate.

Matsuoka ironed out wrinkles by material selection and combination in a few months – an impressive feat. The hard coat transfer film for construction machine resin windows was introduced to the market in February 2015.

“Luckily, my colleagues, younger and older alike, taught me the key points and I studied hard by reading books,” Matsuoka said modestly. His easy-going nature and ability to build friendships – whether at work, the brass band in which he is a trumpeter or when engaging in his hobby of driving cars – helps him solve problems quickly, according to people around him. The gregarious engineer apparently is an unwitting master of making people want to offer him a helping hand.

Pursuing wider applications of resin glass

Matsuoka oversees progress made by researchers assigned to tasks such as examining correlations between the results of experiments on the weather-resistance of resin glass by outdoor exposure and by weatherometers and improving the materials design to boost its bendability. In addition to industrial standards and clients' requests, the team has conducted experiments on the effects of aromatic air fresheners or bird droppings on the resin glass, research ideas gleaned from brain-storming among team members. The team meets once a week so Matsuoka can learn about the challenges each member faces.

As an application of resin glass, the team is considering marketing an ultrathin hard coat for car emblems, behind which an anti-collision or automatic driving system using a millimeter-wave radar is installed to detect pedestrians, vehicles and other objects. If an emblem is uneven, it compromises the accuracy of the radar. This is why emblems in many new models are flat. “We have already applied for the patent for the hard coat we developed for emblems and other purposes because we anticipated such a need would arise several years ago.”

Aiming for the global market

DNP is initially eyeing the Chinese and European markets for the hard coat transfer film, or hard coated resin glass or hard-coated, molded resin glass depending on clients' needs. Its hard coated resin glass has already passed the European Union's industry standards.

“China doesn't have an equivalent to Japan Industrial Standards for such products,” Matsuoka said. “The lack of product standards makes it easier to enter the lucrative market early. When I visited China and looked out from my hotel window, I was stunned by how many cars had sunroofs. It is said 70 percent of cars in China have a sunroof. The sunroofs are indeed targets for DNP's resin glass.”

But the lack of product standards is a double-edged sword. Matsuoka is consulting with experts to deal with risks involved in entering the Chinese market. Meanwhile, DNP is trying to market the resin glass in China, in particular to Tier 1 suppliers that are primary subcontractors of automakers as well as original equipment manufacturers (OEMs), which make finished car products.

OEMs set strict deadlines because carmakers specify a stringent start of production date. Consequently, development of resin glass in line with the client's needs is a race against time. “Client demands, whether they pertain to hardness or moldability, are constantly increasing,” Matsuoka said. “Our primary mission is to meet each client's requirements on schedule.”

DNP plans to start marketing the product abroad, while taking necessary steps to pass the standards for resin glass for automobiles in various countries. The main target markets are mobile items such as rides at amusement parks and cable cars, in addition to automobiles and construction machines.

“We will continue improving our products so resin glass can eventually be formed into any shape and possesses better self-cleanability and stain resistance,” Matsuoka said. “Our job is endless.”

- Tier 1: Primary subcontractors. In the automobile industry, Tier 1 companies directly supply parts to OEMs.

- Published: October 16, 2018

- DNP department names, product specifications and other details are correct only at the time of writing. They are subject to change without prior notice.

October 16, 2018 by DNP Features Editorial Department