DNP Develops Curved Resin Glass for Automobiles

Light with superior transparence, weather and wear resistance

Dai Nippon Printing Co., Ltd. (DNP) has improved the workability of its hardcoat transfer film with superior weather and wear resistant properties, andhas developed a curved resin glass suitable for use in the sun roofs of automobilesand other applications.

[Background]

DNP has positioned Living and Mobility as a business growth area, and hasmade efforts to expand the automobile related business area. Apart from offeringdecorative film for interior purposes and a viewing angle control film targetingin-vehicle displays, in August, 2015, Tamura Plastic MFG Co., Ltd., which maintainsa substantial domestic share in side visors attached to automobile doors, alsobecame a DNP subsidiary. In this way, DNP is moving to strengthen new productdevelopment of automobile related components.

In recent years, amidst the rise in consumer awareness regarding the environmentand safety, there has also been a trend towards tightening CO2 emission controls,and automobile makers have been pressed to come up with responses. Lighter autobodies are effective in reducing emissions and improving fuel efficiency, whileplastic resin glass, such as polycarbonate, maintains superior impact resistanceand thermal insulation properties. In addition, plastic resin glass weighs approximatelyhalf the weight of silicic acid based general glass, leading to increased demandfor its use in automobiles where weight savings are required.

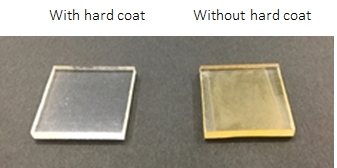

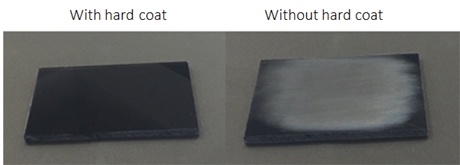

In order to satisfy these needs, DNP has used original technology to developa ultra-weather resistant hard coat transfer film for use with resin glass.By transferring the super-weather resistant hard coat to the surface of resins,such as polycarbonates, it has been possible to improve weather resistance,from sunlight and the elements, as well as wear and scratch resistance.

DNP launched the resin glass with this hard coat in February 2016, and ithas been placed on the market for industrial uses.

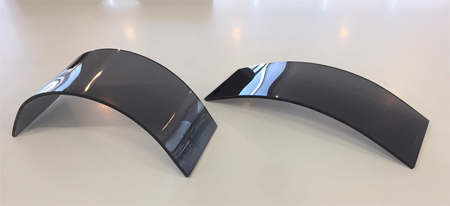

In this latest development, the hard coat layer of the film has been furthermodified in answer to the needs for curved surfaces in automobiles, and curvedsurface follow-ability that had been a challenge with existing products alsoimproved as the Company developed a curved resin glass capable of use with thesun roofs of automobiles. As a result of these developments it has been possibleto create a bending process capable of producing arcs with a minimum diameterof up to 160mm, or a radius of 80mm, based on original DNP methodology.

[Features of Curved Resin Glass]

- The film is transferred at the same time as the extruding of the polycarbonateresin, then bent. As a result, it is not only possible to reduce processingcosts compared to existing methods that form the hard coat layer by spraycoating and so forth following molding, but the manufacturing process canalso be shortened.

- The weight is approximately half that of general silicic acid basedglass.

- It holds transparency equivalent to general glass.

- It has been possible to create a bending process capable of producingarcs with a minimum diameter of up to 160mm, or a radius of 80mm facilitatinguse in the sun roofs of automobiles.

- The newly developed product exhibits superior impact resistance, andas it is more difficult to break compared to ordinary glass, also meansthat it maintains superior safety features.

Curved resin glass product

Photographic comparisons (weather resistance tests)

Photographic comparisons (wear resistance tests)

[Forward Looking Developments]

DNP will market the curved resin glass product based on the newly developedfilm for mobility uses, including automobiles, busses and railway carriages,aiming for sales of 5.0 billion yen in FY 2020.

DNP has positioned Lifestyle and Mobility as a growth area, and aims to providecomfort in a variety of spaces, beginning with housing, offices, schools, commercialfacilities, and including automobiles and trains, at the same time as endeavoringto ensure secure information services that can be used anywhere, anytime.