Casting light on the world's first commercial Lippmann holograms

Masachika Watanabe still remembers the disappointment he felt two decades ago when he presented a Lippmann hologram sample—the result of months of hard work by his team—to Dai Nippon Printing Co., Ltd.’s top leaders.

“Are you using light again?” and “Can’t you make the hologram much brighter?” were among the cynical reactions he received from the executives, who nonetheless pinned high hopes on developing technologies for Lippmann, a highly sophisticated form of hologram that excels in artistic productions and, in particular, security.

When lit by spotlight and other parallel lights, the sample looked excellent, successfully recreating the colors and solidness of an object. This was a leap forward in itself, considering that DNP was the only company at that time with the technology to mass-produce Lippmann holograms. After viewing the sample under normal fluorescent lighting, however, the executives found it too dark to see, and thus were negative about marketing the hologram as it stood.

“I realized we had to make it much brighter, otherwise DNP wouldn’t be able to cater to consumers’ needs,” recalls Watanabe, previously a top researcher of Lippmann holograms, now a general manager in charge of overseeing hologram technology at DNP.

Creating much brighter holograms

This experience drove Watanabe, now 47, to take on the daunting challenge of making holograms much clearer and brighter—an area in which rival firms had yet to succeed. “I discovered that controlling the viewing angle in the hologram was effective in making it brighter, as doing so could gather light [in a narrower area],” Watanabe explains. “I calculated how the interference patterns [irregularities created by splitting a laser beam into two] should appear, and under which conditions they should be recorded to make the viewing angle narrower.”

In 1998, his efforts finally paid off when his team produced samples that included a depiction of Astro Boy. Thrusting his left fist into the air, the cartoon character’s 3-D body shone brightly against a blue background under fluorescent light—the brightness of the team’s holograms was no longer in dispute.

Holograms made using Lippmann holographic technology; were marketed in 1998, making DNP the first in the world to commercialize such products by establishing technologies for origination, mass-production and special adhesion.

Security-related holographic technology evolving

|

|---|

Lippmann holograms have evolved since then, and DNP now concentrates its focus on the security field. “DNP’s strengths lies with security products,” Watanabe says, explaining that Lippmann holograms are extremely difficult, if not impossible, to counterfeit. “Strict control of the materials needed to manufacture Lippmann holograms prevents criminal groups from counterfeiting them, or any attempt to copy them for other products. In addition, our original, patented technology makes it harder for others to newly enter the market.”

The following are some of the breakthrough products that DNP has introduced:

- 2002 : A holographic label used to verify authenticity that employs various kinds of anti-counterfeit features

- 2006 : A hologram that “animates” by switching between two or three images when tilted to different angles

- 2007 : A hologram that is capable of storing data from computer graphics and video images by using stereogram technology developed in collaboration with Sony PCL Inc.

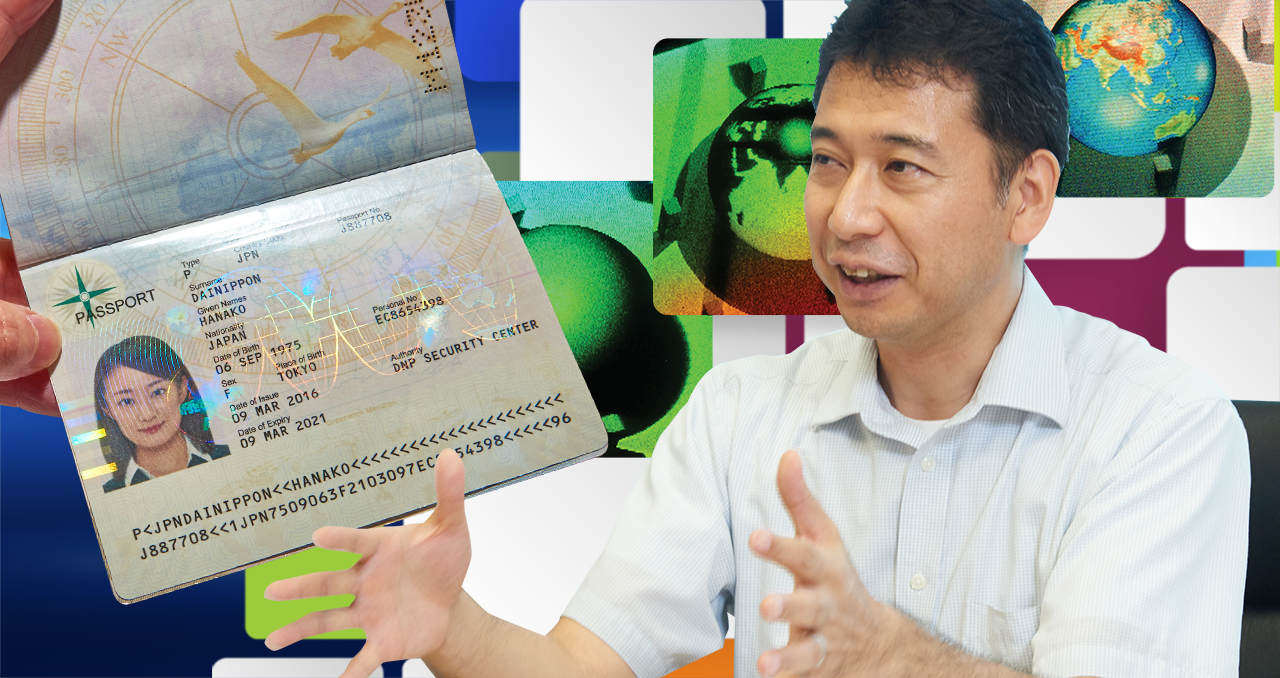

- 2009 : World’s first transparent Lippmann transfer foil developed for passports

Lipmann technologies have since been upgraded to enable DNP to make products from 3-D computer-graphic data, while improving quality and mass-production capability.

DNP’s Lippmann holograms are now used for credit cards, company identification cards and brand protection, etc.—all of which are required to be counterfeit-proof.

Excellent for artistic uses

|

|---|

Compared with embossed holograms, Lippmann holograms cost more to produce, which, until recently made many clients reticent about adopting them despite their outstanding artistic designs. This is no longer the case, however.

In 2012, a black, premium IC card with an embedded hologram developed by DNP for The Kyushu Card Co., Ltd. won a Best Card Design award from VISA. The card’s unique appearance featured Lippmann holographic images embedded between the multiple layers that make up a single card.

Targeting a ¥5 billion-per-year business

Watanabe speaks unassumingly about the feat he accomplished in the realm of Lippmann hologram technologies, but his facial expressions mellow when he talks about his three sons, with whom he spends the majority of his weekend time. “I like playing with them, and we often play soccer together,” he said. “I don’t think about holograms during my free time because I think about them incessantly during the week.”

|

|---|

Watanabe’s immediate goal is to grow earnings from DNP’s hologram business alone to ¥5 billion a year. “Lippmann holograms are the most realistic 3-D printing technology around today,” he says. “In addition to artistic products and security purposes, we’d like to explore new horizons for holograms, including industrial uses, thereby expanding our sales from the hologram-related domains.”

- *DNP department names, product specifications and other details are correct only at the time of writing. They are subject to change without prior notice.

November 30, 2016 by DNP Features Editorial Department