Exploring the Potential of Artellion®, Decorative Materials That Mimics Wood, Stone, and Even Water, with Experts!

Artellion, an aluminum panel developed by DNP, combines the functional benefits of aluminum—lightweight structure and exceptional weather resistance—with the creative freedom of fully customizable printed designs. But what role would Artellion play in the future of architectural expression? And how does it empower architects to push the boundaries of creativity? In an inspiring roundtable discussion, Rempei Goto, Editor-in-Chief of the architecture web magazine architecturephoto, joins members of the DNP team behind the product’s development and design. Together, they explore how Artellion sparks new ideas and reimagines the future of building design.

- From handmade to ready-made: The evolution of decorative materials

- Advanced printing that captures the look of wood, even from afar

- Able to take the form of stone, metal—or even water

- Customization that surpasses handcraftsmanship — Artellion unleashes architectural creativity!

|

|

[Profile] (from right to left)

Mr. Rempei Goto Born in Iwata, Shizuoka Prefecture in 1979. Graduated from Kyoto Institute of Technology in 2002 and completed graduate school there in 2004. After gaining practical experience at an organizational design office and a small-scale design firm, he founded architecturephoto inc. He has been sharing architectural information for 22 years and is currently primarily involved in managing the online media platform “architecturephoto,” which visualizes the relationship between architecture and society. His publications include “A Lecture on Web Outreach for Architects” (Gakugei Shuppansha).

Yuki Egawa: Responsible for Artellion sales in Integrated Planning&Marketing Division, Living Space Operations, Dai Nippon Printing

Eri Shima: Supports sales activities related to Artellion in Integrated Planning&Marketing Division, Living Space Operations, Dai Nippon Printing

Hinako Nakamura: Responsible for Artellion design in Innovative Design Center, living Space Operations, Dai Nippon Printing

Kosuke Nakai: Responsible for Artellion development in Technical Department, DNP Elio Co., Ltd.

From handmade to ready-made: The evolution of decorative materials

— Today’s theme is decorative materials. They’re essential to every structure—but how do architects truly see them?

Rempei Goto: I once heard that some top architecture firms begin the design process by sourcing decorative materials from around the world. It highlights just how central materials are to an architect’s creative vision. As the word “sourcing” implies, most decorative materials used on construction sites today are prefabricated or off-the-shelf. But when I worked on seismic assessments of old wooden homes, I saw a different world—buildings from the late ’60s and ’70s often featured handcrafted elements made by skilled artisans. That kind of craftsmanship is far less common now.

— What do you mean by “more handcrafted elements?”

|

|---|

| Example of an exterior wall using siding panels |

Goto: For example, many buildings used to have earthen walls, and plaster materials like mortar*1 and lime-based stucco were commonly applied by skilled craftsmen working by hand. Today, however, most exterior walls are covered with siding panels—a prefabricated system installed on-site by workers. While installation still requires craftsmanship, the use of these ready-made panels helps shorten construction time and improve durability, meeting the practical demands of modern society.

* 1 Mortar: Decorative materials made by mixing cement, sand, and water

On the other hand, heavy reliance on prefabricated materials might make it more difficult for architects to express originality in their designs. Many architects likely feel a strong desire to create something entirely from scratch, based on their own vision. However, budget constraints and other practical factors often make this challenging. As the industry continues to shift toward prefabrication, modern architects must develop the ability to identify decorative materials that still allow for creative, one-of-a-kind designs.

Advanced printing that captures the look of wood, even from afar

— With that theme in mind, we want to delve into how the decorative material Artellion approaches this challenge. To start, how did DNP originally come to develop Artellion?

|

|---|

| Artellion used on the Shanghai Maxdo Center (constructed in 1999) |

Kosuke Nakai: Artellion first took shape about 25 years ago, when we were asked to supply aluminum panels for the exterior of the Shanghai Maxdo Center. It wasn’t yet a full-fledged product, but that project sparked its development.

Artellion’s weather durability was well established early on. Its installation on the Shanghai Maxdo Center helped build momentum, and by 2010, it was increasingly used in projects in Japan. In 2014, it entered the North American market, leading to a wider range of design variations and enhanced production capabilities.

Yuki Egawa: The current Artellion has passed accelerated weathering tests—designed to simulate long-term exposure to outdoor conditions—and has been shown to maintain its integrity for at least 20 years. At the Shanghai Maxdo Center, the panels remain in excellent condition even after more than two decades.

— How has Artellion gained traction in construction projects over the 25 years since its initial adoption?

Nakai: Back in 2013, Kengo Kuma, who had been seeking durable wood materials, used Artellion for the renovation of Tamagawa Takashimaya in Tokyo’s Setagaya Ward. That project really helped raise its profile bit by bit. It’s still not widely known, but interest is definitely growing.

|

|---|

| DNP Eri Shima |

Nakai: Back in 2013, Kengo Kuma, who had been seeking durable wood materials, used Artellion for the renovation of Tamagawa Takashimaya in Tokyo’s Setagaya Ward. That project really helped raise its profile bit by bit. It’s still not widely known, but interest is definitely growing.

Eri Shima: The way Kuma boldly incorporates wood in his buildings pairs naturally with Artellion’s high durability and versatile design options.

For example, Forest Gate Daikanyama in Shibuya, Tokyo, features a distinctive design that resembles stacked wooden boxes, and uses wood-grain Artellion for its exterior.

|

|---|

| Forest Gate Daikanyama (constructed in 2023) |

Goto: What I found interesting in the interview with Kengo Kuma on Artellion’s official website *2 was how they manipulate the scale and shading of the wood grain to make it look more natural. I understand that the wood grain is intentionally magnified so it stands out clearly, even at a distance.

* 2 August 2021 Interview: Kengo Kuma and Associates “Kengo Kuma on DNP Aluminum Decor Panel and the Future Challenges of Architecture” https://www.dnp.co.jp/biz/case/detail/20173079_4968.html

(in Japanese only)

|

|---|

| Artellion wood grain pattern used at Forest Gate Daikanyama |

Hinako Nakamura: Yes. If the pattern is the same scale as real wood grain, it ends up looking like a plain beige wall when viewed from across the street. In that sense, the exterior design of Forest Gate Daikanyama really makes the most of one of Artellion’s key strengths—the ability to freely adjust the scale of printed patterns.

|

|---|

| Artellion used at Forest Gate Daikanyama |

Goto: I see—that’s why the wood grain is intentionally emphasized. It feels like this goes beyond simply replicating wood and opens up new possibilities.

|

|---|

| Tokushukai Gymnastics Arena (constructed in 2024) |

Shima: Regarding expanding design possibilities, the Tokushukai Gymnastics Arena in Kamakura, Kanagawa, which is south of Tokyo, stands out. The louvers*3 feature wood-grain Artellion panels with sharp contours that would be impossible to achieve using natural wood.

*3 Louver: Narrow slats arranged vertically or horizontally at regular intervals, mainly used in doors and windows.

Able to take the form of stone, metal—or even water

— Is Artellion often used in designs that make use of the texture of wood?

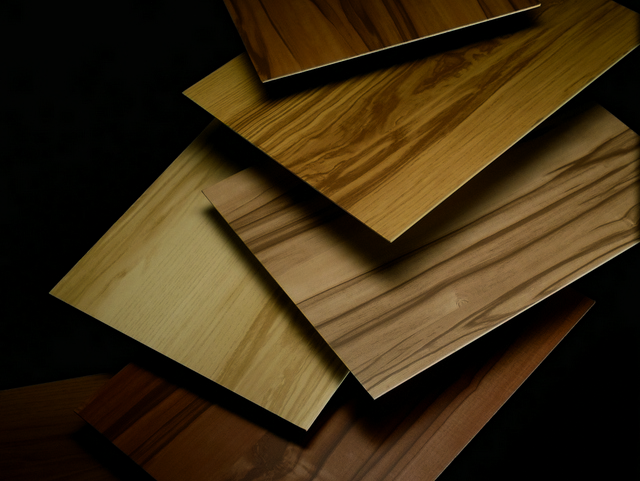

|

|---|

| Haseko Minami-Sunamachi Station Building using stone-patterned Artellion panels (Koto Ward, Tokyo, constructed in 2018) |

Nakamura: We often receive orders for designs inspired by materials other than wood. For example, in buildings like department stores and banks, stone is used to create a stately appearance. However, while genuine stone is usable on the lower floors, it’s not feasible for the upper floors—such as the third or fourth—due to safety and weight considerations. In such cases, we use Artellion to seamlessly finish those upper sections. It perfectly replicates the texture and feel of the stone used below while also being lightweight and suitable for high-rise installation.

|

|---|

| Artellion replicating granite (Mikage stone) |

With Artellion, it’s even possible to create the look and feel of stone without using actual stone. This is achieved through a “base material preservation” printing process that maintains the aluminum’s natural texture, resulting in a striking contrast: the appearance of stone combined with the tactile quality of metal.

|

|---|

| Artellion featuring a phosphate pattern |

Nakai: One of Artellion’s strengths is its ability to deliberately recreate patterns that normally occur randomly in nature—for example, the unique “phosphate pattern” that forms on metal surfaces treated with phosphoric acid*4.

Nakamura: Due to their attractive visual characteristics, phosphate patterns have been used in a variety of product designs. However, because they occur naturally, the pattern formation is highly unpredictable and difficult to control.

* 4 Phosphating: A plating process used to enhance the corrosion resistance of metals

— So in other words, you don’t know what the final pattern will look like until the process is complete?

|

|---|

| Rose gold phosphate pattern |

Nakamura: Exactly. With Artellion, since it’s printed, we create the ideal phosphate pattern and even adjust the colors. Phosphate patterns are typically a dark gray, but we are able to make them lighter, like silver, or even darker, like black. We’ve even created one in rose gold.

Shima: When light hits the rose gold phosphate pattern, it’s incredibly beautiful.

|

|---|

| Hulic Kinshicho Collabo Tree (completed in 2023) |

Nakai: Artellion’s rose gold phosphate pattern is featured in the Hulic Kinshicho Collabo Tree (Sumida, Tokyo). The color shifts with the angle of sunlight, so its appearance changes throughout the day—making for a truly unique design.

Goto: If you are able to intentionally create patterns that usually occur by chance, does that mean effects like aging or weathering are reproducible? It seems that many architects find beauty in the natural changes materials like wood undergo over time.

|

|---|

| Artellion with a glossy rust-like finish |

Nakai: Yes, we do have clients who specifically request an “aged look”—for example, something that appears to have weathered over about 20 years.

Nakamura: In fact, there’s also an Artellion finish that replicates rust. Real rust doesn’t reflect light, but with Artellion, we are able to create a glossy, rust-like effect, which makes it more suitable for architectural use.

Goto: That’s interesting. Of course, the inherent qualities of real materials hold intrinsic value, but it’s fascinating that starting from their replication, there are technologies and possibilities to customize in many ways.

|

|---|

| Opposing wall at Shin-Tsunashima Station (completed in 2022) |

Shima: One example that’s difficult to achieve with traditional decorative materials is the opposing wall at Shin-Tsunashima Station on the Tokyu Shin-Yokohama Line. Tsunashima, where the station is located, is known as the “river town” because the Tsurumi River flows through it. So, the design theme for the platform was “water.” To capture that, we used a blue square pattern inspired by gentle ripples. It’s really the kind of design only possible with Artellion.

— It’s fascinating how you take an element like water, which isn’t naturally a decorative material, and express it in architectural design.

|

|---|

| DNP Hinako Nakamura |

Nakamura: Especially with projects in tourist destinations, we often get requests to reflect the town’s identity in the architecture. So when we’re asked to incorporate themes like rivers or forests, it becomes a rewarding creative challenge to interpret those motifs in material form.

— That flexibility is admirable, but doesn’t it also mean you have to be just as flexible with client demands? I imagine that must come with its own set of challenges during the design and development stages.

Nakamura: That’s right. Sometimes we create and propose multiple samples to meet detailed requests, and I even visit the factory myself to negotiate directly, saying things like, “Can we make it a bit redder?” (laughs). In addition, we’re constantly building up a stock of patterns to allow us to respond flexibly when requests do come in. That stock has likely grown to over 10,000 patterns.

|

|---|

| DNP Kosuke Nakai |

Nakai: On the development side, we’re constantly exploring ways to flexibly combine existing specifications to accommodate any request and make them technically achievable.

Egawa: Our standard specifications provide a starting point, but Artellion designs are typically customized for each individual project. Reusing previous designs as-is certainly are an option, but we also offer tailored adjustments—such as altering colors or adjusting pattern intensity. Another key advantage is that we don’t impose minimum order quantities, allowing us to accommodate small-batch orders as well.

|

|---|

| Mr. Goto, holding an Artellion sample in his hand: “Even if the color and pattern are the same, just a slight difference in gloss might completely change the overall impression.” |

Customization that surpasses handcraftsmanship — Artellion unleashes architectural creativity!

— We’ve explored many of Artellion’s advantages so far. While it’s still a relatively new decorative material, how is it currently being received by the architecture industry?

|

|---|

| DNP Yuki Egawa |

Egawa: Architects generally prefer to use “the real thing” when it comes to decorative materials. So when we introduce Artellion to someone for the first time, the typical response is, “So it’s fake, then?” That’s usually where the conversation starts. From there, we explain that it’s not just a replica—it’s a material with unique strengths that open up new creative possibilities.

Goto: It’s true that one of Artellion’s key features is its ability to reproduce the colors and patterns of natural materials—in that sense, it may be seen as a kind of fake. But after hearing today’s discussion, I’ve come to think that Artellion’s real value lies beyond reproduction: it’s in its capacity to generate unique value through original patterns and bold ideas.

To promote Artellion going forward, I think that aspect should be emphasized more. After all, if genuine wood is available, architects who prefer authenticity will likely choose real wood over Artellion. On the other hand, Artellion holds the potential to create things the world has never seen by constantly evolving ideas and pushing design boundaries.

Nakai: Absolutely. With recent improvements in Artellion’s design quality, it’s increasingly chosen not only because it reduces maintenance costs and is lightweight, but also for its many other advantages. Sometimes, even when natural materials could be used, Artellion is preferred.

Egawa: When durability is a concern, we often mention that some buildings constructed with Artellion have already lasted more than 20 years. This assurance is particularly important for large-scale projects with major contractors and public facilities, where safety is paramount.

Goto: There’s also a rising social demand for buildings that are easier to maintain, and Artellion is very much in line with that trend.

— It’s clear that Artellion holds great potential as a decorative material. To end, Mr. Goto, could you tell us your thoughts on this roundtable and how you see Artellion being used in the future?

|

|---|

| Rempei Goto |

Goto: I was surprised by how highly customizable Artellion is, despite being a prefabricated product. At the same time, I felt that it really challenges the “vision” of the architect using it. The more imaginative the architect, the more precisely they are able to create Artellion that fits their detailed requirements.

That’s why I believe Artellion empowers architects to create iconic designs that become their signature—much like Kengo Kuma’s wooden louvers or Tadao Ando’s exposed concrete. Collaborating with DNP to develop such decorative materials could play a vital role in their personal branding and, most importantly, make the creative process much more fulfilling.

*Please note that the information contained in this story was accurate as of the publication date.

October 23, 2025 by DNP Features Editorial Department

Discover more

Related products and services

Artellion(Open in a new window)

DNP’s Artellion, a high-value added aluminum panel series, provides unique and rich expres...

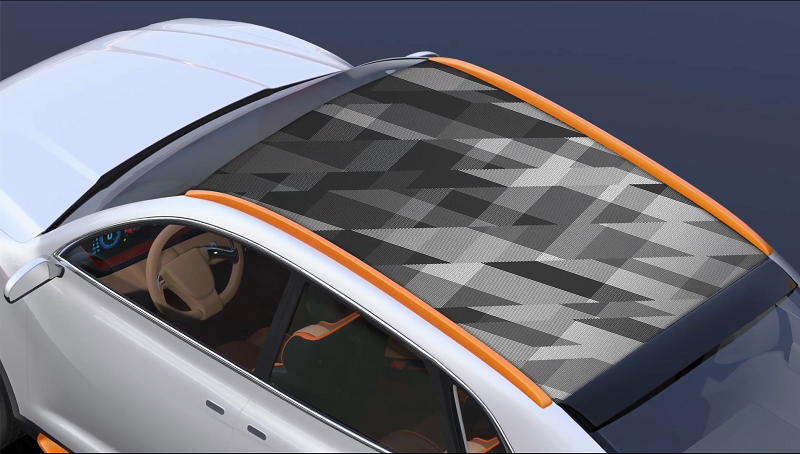

Exterior decoration films Roof decal(Open in a new window)

DNP can meet the requirements of various kind of decorative pattern from customers. Two to...