DNP, Hanshin Expressway and Kurabo Develop Emergency Repair Sheet to Prevent Peeling of Concrete in Aging Structures such as Bridges

Facilitating repair works by integrating new adhesive and fibrous sheet

Dai Nippon Printing Co., Ltd.

Hanshin Expressway Engineering Company Limited.

KURABO INDUSTRIES LTD.

Dai Nippon Printing Co., Ltd. (DNP), Hanshin Expressway Engineering CompanyLimited (Hanshin Expressway), and KURABO INDUSTRIES LTD. (KURABO) have jointlydeveloped emergency repair sheet capable of preventing peeling of concrete inaging structures. The newly developed product provides emergency repairs toconcrete cracking or other defective areas, discovered when inspecting viaducts,tunnels, etc., and is used to increase safety until full scale repairs can beconducted.

[Background]

Japan is now facing the reality that much of the current infrastructure,such as the roads and railways constructed during the period of high economicgrowth, is now aging. Instances of accidents involving concrete peeling andfalling have become a social issue. As a countermeasure, regular inspectionsof concrete structures, and in cases of cracking or other defects, the concretein those and surrounding areas has been removed, and repairs made to preventfurther peeling. As the risk of peeling remains throughout the period from inspectionto repair works, there has been a demand for emergency measures to reduce concretepeeling.

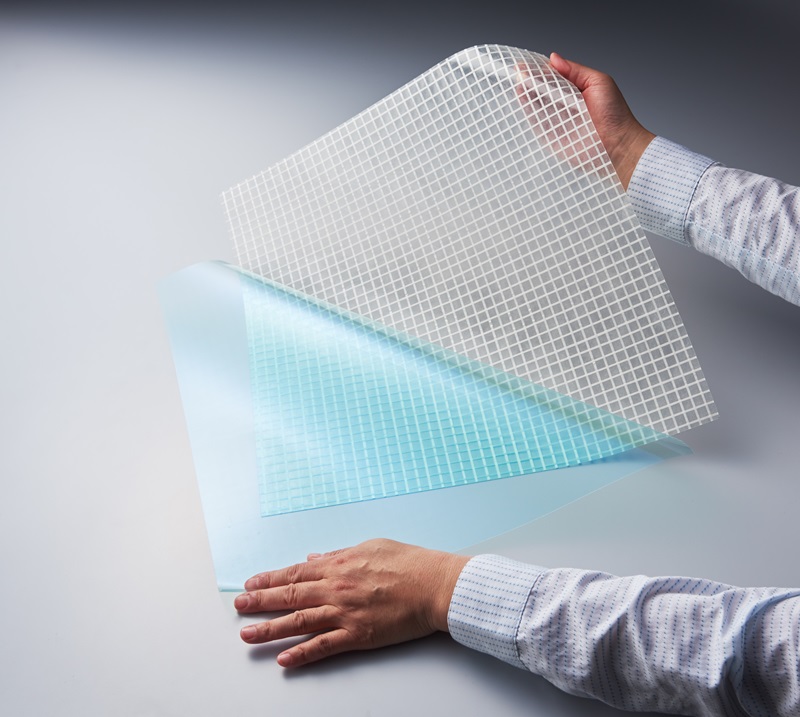

The partners have risen to the challenge and developed sticky-back emergencyrepair sheet that integrates special adhesives with a reinforced fiber net.

[Product Features]

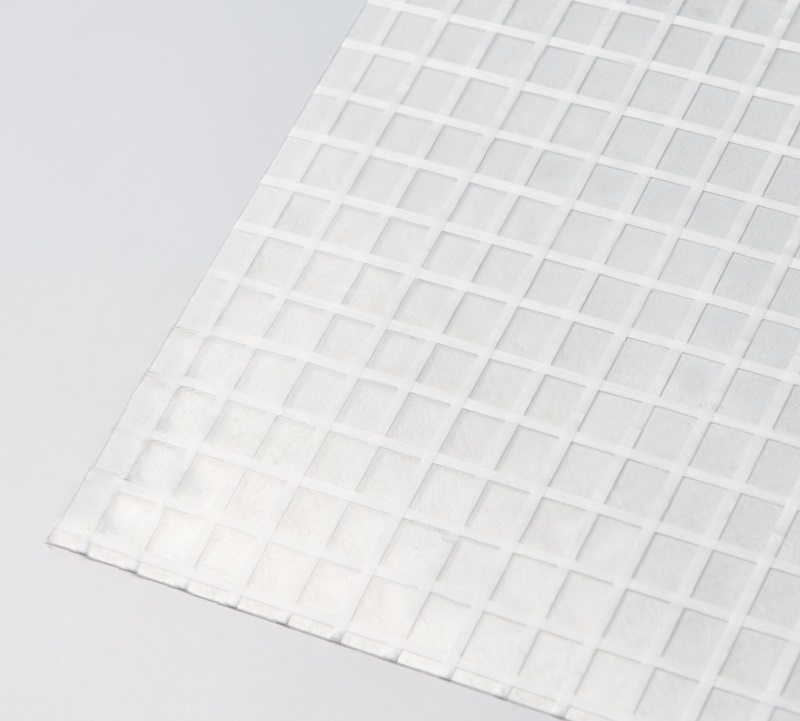

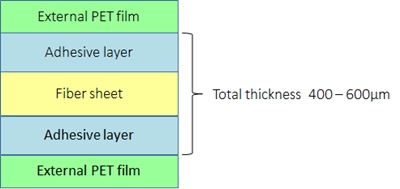

The newly developed product makes it possible to immediately perform emergencyrepairs on concrete cracks and other defective areas discovered when inspectingviaducts and tunnels. The new product is a sticky-back sheet with Crenette,the high strength polyethylene fiber developed by Kurabo, laminated on the adhesivelayer as developed by DNP.

Major features

- It is possible to perform repairs to defective areas in a simple manner,merely by stripping away the external polyester (PET) film, and adheringit to the concrete, following the uniform coating of the defective concretesurface with a primer to smooth it.

- Curing of the adhesive agent can be performed via irradiation with ultravioletrays found in sunlight or fluorescent light.

- Current repair works (employing polymer cement mortar etc.,) requiretwo days per square meter. By way of comparison, similar tasks involvingthe newly developed product take about 30 minutes only.

- It is also possible to reduce risks in the period between the discoveryof the defective area and the implementation of permanent repair works.

- In load (punching) tests to assess prevention performance anticipatingconcrete peeling, the newly developed product achieved approximately 2.5kN,in excess of the 1.5kN minimum required value for repairs, and comprisingthe basic performance qualities necessary as an emergency repair material.

- The repair sheet contains only a low organic solvent content in itsmaterials including adhesive that can be the cause of environmental pollution,and is an eco-friendly product with no perceivable odor emitting.

[Looking Ahead]

DNP, Hanshin Expressway, and KURABO will perform field tests, and use theassessments and knowledge obtained there for marketing activities, aiming tocommercialize the newly developed product in FY 2016.