DNP Develops New Decorative Film with Texture Effect Compatible with Injection Molding Process

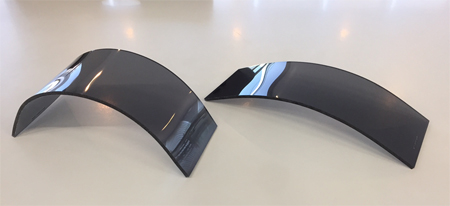

Provides expressions with real tactile sensations for use in automobile interiors

Dai Nippon Printing Co., Ltd. (DNP) has developed a new type of decorativefilm capable of expressing a variety of tactile sensations through a set ofunique surface textures. The new decorative film adheres to the resin part,while it is being molded, by applying the thermal pressure generated byinjection molding, in a process referred to as a simultaneous molding and decorationprocess. The new film will be marketed mainly for automobile interiors, aimingto capitalize on its unique visual and tactile effects.

[Background]

DNP has positioned Living and Mobility as a business growth area, and isworking to expand the automobile related business area. The Company offers decorativefilm as interior materials to auto makers in Japan and overseas. These includewood grain and metallic design features applicable with both simultaneous moldingand decoration process and the methods used with decorative processing afterinjection molding. Demand for such interior materials from auto makers and consumershas been rising year by year. And, users have begun to call for a greater varietyof design effects, including not only visual elements, but also a sense of luxury,comfort, touch and originality. In answer to these needs, DNP has developeda new decorative film based on the simultaneous molding and decoration processto provide not only a unique visual effect, but also a tactile sensation allowingusers to confirm the texture by running their fingers over the surface.

[Features of the New Decorative Film]

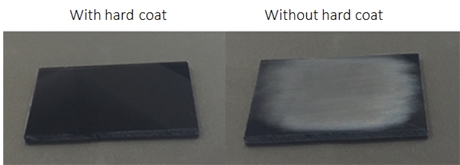

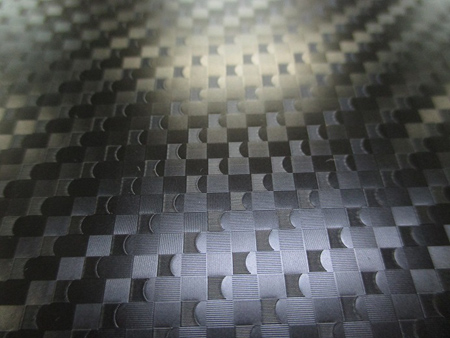

- With currently used simultaneous molding and decoration process, thedecorative film is pressed into a mold using heat and pressure. Doing soresults in the loss of the surface texture, making it difficult to achieveany tactile sensation. Processing methods that provide for such sensationsinclude vacuum pressure forming, which is capable of decorating the resinmolded parts without applying a significant thermal pressure to the parts.In this latest development, however, DNP has successfully developed a decorativefilm capable of providing a tactile sensation using the simultaneous moldingand decoration process that has become the mainstream process for producinginterior materials for automobiles.

- By reviewing the film composition and providing a protective layer thatabsorbs the thermal pressure, it has been possible to maintain the surfacetexture even after the simultaneous molding and decoration process, to achievea tactile sensation.

- The newly developed decorative film is compatible with existing simultaneousmolding and decoration processes that are superior in terms of cost as amainstream manufacturing method, and as a result, it is now possible toprovide a tactile sensation at lower costs than before.

- Compared with methods that configure texture with a metal mold, it ispossible to provide a variety of textures by changing the decorative film,improving pattern flexibility as a result.

DNP New Decorative Film

Cross Section Image

[Manufacturing Process]

During the molding processes, the protective layer on the surface of thedecorative film absorbs heat and pressure, and by removing that layer followingcompletion of the molding, it is possible to achieve a molded product that maintainsthe textures of the film surface.

[Forward Looking Developments]

DNP will market the newly developed decorative film for mobility uses, suchas automobiles, busses and aircraft, aiming for sales of 5.0 billion yen inFY 2020.