DNP Develops New Type of Micvac(R) Container Enabling Longer Shelf Life and Less Food Loss

May31,2017

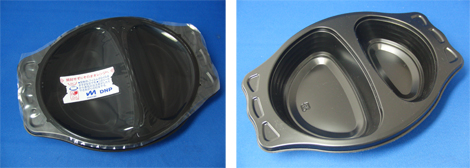

A variety of menus now possible with two kinds of foods in a single tray

Dai Nippon Printing Co., Ltd. (DNP) has developed a new type of Micvac® container designed to extend the shelf life of ready meals, and reduce food loss. The newly developed container is a dual compartment type, produced in answer to increasing demands for containers that would allow the storage of popular complete meals, such as curry and rice, or pasta with a side dish. Micvac ® is a pasteurized cooking system marketed by DNP since 2012, and the Company will now look to market a line of dedicated pasteurized packaging along with packaging materials.

[Development]

In line with lifestyle changes, including the shift towards more meals being eaten alone and shorter cooking times driven by the increase in single person and dual-income households, there has been an expansion in demand for ready meals that can be heated in microwave ovens. DNP has signed a licensing agreement with the Swedish company Micvac that developed Micvac® as the optimal packaging to answer such needs. Micvac® is a system that allows users to fill dedicated containers with foods, before sealing and heating in a microwave oven to complete cooking and pasteurization in just a short time. As a result, none of the nutrients, such as vitamins, are lost, while the original taste of the foods, such as the crispiness of vegetables, is also maintained. In addition, with Micvac® it is possible to store foods for extended periods in cold storage, and as the extended best-by date also facilitates reduced food loss, we are seeing expanded domestic use. DNP has developed a dual compartment tray, which will make it easier to deliver nutritionally well-balanced and complete meals.

Such trays are already in use in Europe with meals such as curry and rice. In this latest development, in addition to making the handgrip bigger in order to make it easier to hold, the format has been redesigned for Japanese use, including a tray that will not break easily even if dropped, along with the creation of a more compact size.

[Micvac®]

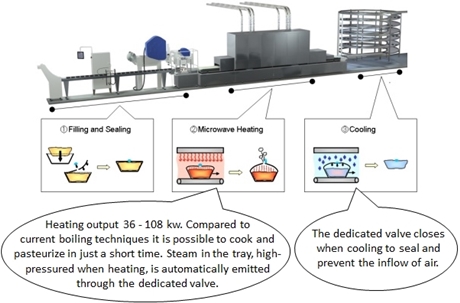

The Micvac® manufacturing process is as follows:

1. Dedicated trays are filled with foods and seasoning sauces, and sealed with a film that serves as the lid.

2. Simultaneous cooking and pasteurizing of foods is performed via microwave heating, then,

3. the contents are rapidly cooled.

The specialized valve, or label, attached to the lid of the film releases steam as the internal pressure rises in line with heating, and seals and prevents the inflow of air in the cooling process. This function enables in-tray pasteurized cooking. Ready meals produced with this system feature superior extended shelf life qualities, and are also effective in reducing food loss. In this latest development, by making an adjustment to the sealed part of the divider between the dual compartments, DNP has made it possible to simultaneously cook and pasteurize both compartments with just a single valve.

- Micvac® Manufacturing Line

[Future Developments]

DNP will propose the Micvac® manufacturing line and packaging materials to domestic food makers, aiming for sales of 1.2 billion yen in FY 2020.

* MICVAC® is a registered trademark of DNP

* Product prices, specification and service contents mentioned in this news release are current as of the date of publication. They may be changed at any time without notice.

- Select location

-

- Category

-