DNP to Market Low-Profile, Light-Weight, Sheet-Type Surface Light Emitting LED Lighting to Plant Factories

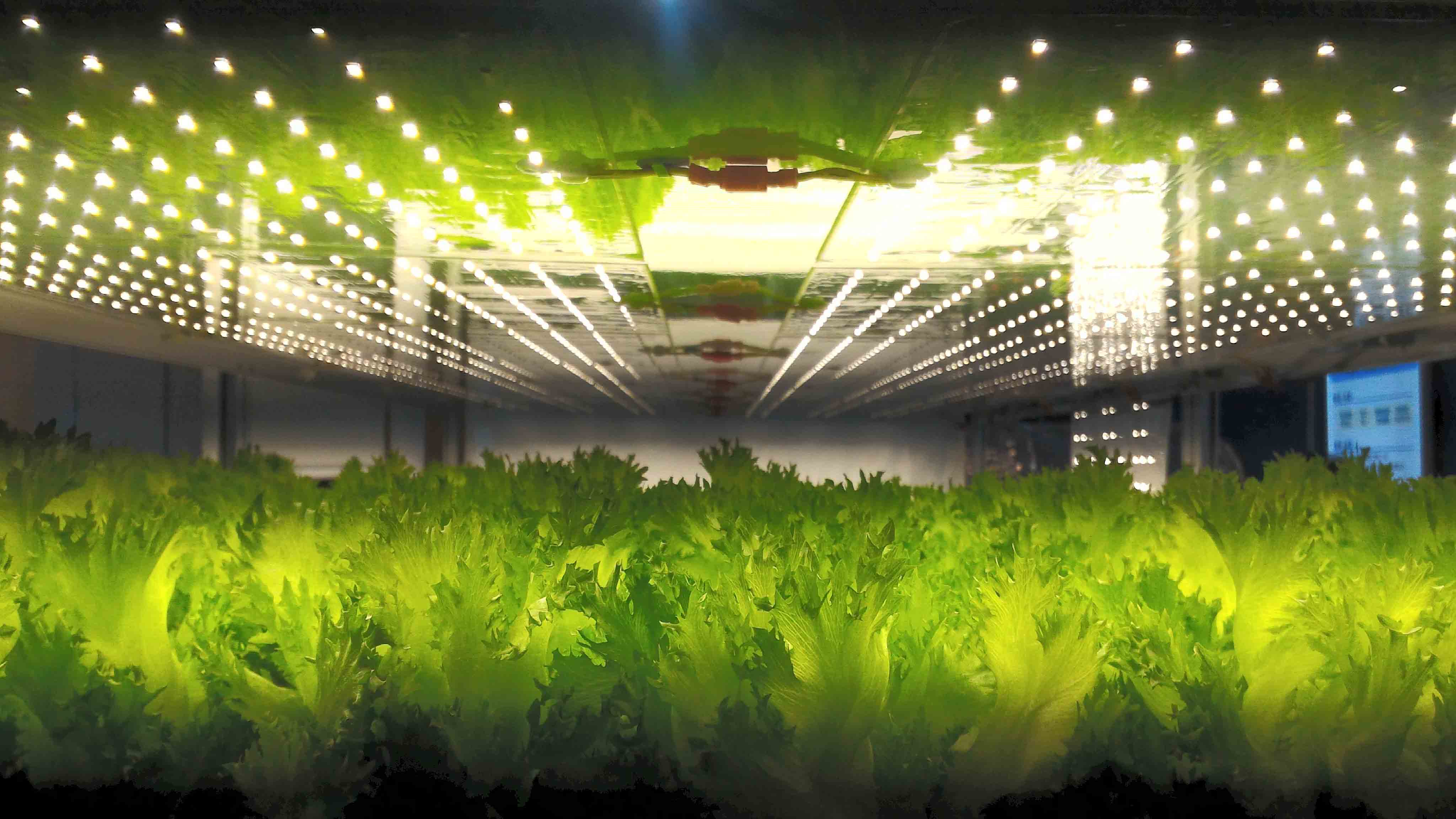

Dai Nippon Printing Co., Ltd. (DNP) is pleased to announce the launch of volume production and full-scale marketing of low-profile, light-weight sheet-type surface light emitting LED lighting to plant factories.

Plant factories that utilize artificial light are expected to see growth in the future against the backdrop of efforts to improve food self-sufficiency, stable supply and food safety.

[Background]

Amidst the increased demand for fresh and safe agricultural products seen in recent years on the back of heightened consumer awareness of health, attention has focused on the stable supply of food from plant factories.

This has occurred, as the production of agricultural crops via traditional outdoor-cultivation has become susceptible to the impact of the changing climate, disease and damage from pests.

At the same time, increased awareness of food safety has fueled demand for plant factories capable of organic or low pesticide cultivation.

In addition to promoting the photosynthesis of crops via the effective use of high-reflectivity, driven by film processing technology derived from printing technology, and the application of microfabrication technology, the Company also offers film with superior stain-proof properties.

In this latest development, the Company will target plant factories with the launch of the full-scale marketing of low-profile, light-weight sheet-type surface light emitting LED lighting, which can be installed on either the top surface or sides inside cultivating equipment.

By combining the newly marketed LED lighting with currently available highly reflective film, it will be possible to improve crop cultivation.

[New Product Features]

The product being released in this latest development is sheet-type LED lighting that can be used as a light source by plant factories that rely on artificial light.

The sheeting maintains a low profile, with a thickness of approximately 0.1mm, while also being light-weight at less than 100g for a single sheet unit of 560mm X 390mm in size. And as the sheeting is also flexible, it can also be easily installed in a variety of locations, including the top surface or sides of cultivation equipment.

At the same time, the photosynthetic photon flux density, or PPFD, is 250 μmol /m2/ s right at a point 20 cm directly below the lighting, creating superior uniform surface light emission. This in turn is expected to reduce uneven crop development and the incidence of tip blight.

[New Product Merits]

Using the newly marketed LED lighting in the cultivation of leafy vegetables, such as lettuce and spinach, leads to improved productivity, evidenced in weight increases of crops and shortened cultivation periods compared to the use of tubular fluorescent and LED lightings.

For example, based on in-house estimates, LED lighting captured a yield of 1.5 to 2.0 times greater than that captured when using tubular lighting.

Also, installing the reflective film around the outside of the cultivation rack further improved the lighting environment, while growth was also boosted.

[Looking Ahead]

DNP will market the new LED lighting and reflective film to manufacturers of cultivation equipment for plant factories, and plant factory operators, aiming for sales of approximately 2.5 billion yen annually by 2021.

Looking ahead, the Company will continue to develop products and technology that lead to improved productivity at plant factories, and will contribute to the stable supply, safety and securing of food.

* Product prices, specifications and service contents mentioned in this news release are current as of the date of publication. They may be changed at any time without notice.

- Select location

-

- Category

-