DNP to Engage in Full-Scale Marketing of Chemical Carrier Bags for Use with Chemical Transportation Containers

To facilitate repeated use of containers, and boost anti-pollution efforts

Dai Nippon Printing Co., Ltd. (DNP) will commence the full-scale marketing of chemical carrier bags.

By using these bags as the inner packaging of various transportation containers in the shipping of chemicals, including industrial materials, it will now be possible to reuse containers, and boost anti-pollution efforts.

The new chemical carrier bags have been developed by DNP in response to demands to reuse various transportation containers without the need for washing. Demands have also been seen for the prevention of contamination by dust and dirt, and the new bags have developed a firm reputation in the transportation of liquid crystal resistant packaging.

In this latest development, the Company has extended uses to adhesives, inks and high purity chemicals, and will commence full scale marketing activities.

[Features]

DNP developed chemical carrier bags are a "clean inner packaging" to be used in combination with a variety of transport containers, such as the containers and drums used to transport chemicals.

By adopting such inner packaging, it becomes possible to reuse plastic containers that would otherwise be discarded due to the staining of the inner surface. As a result, it will also be possible to reduce the volume of plastic waste.

In addition, as the transported chemicals do not come into direct contact with the transport containers, the chemical carrier bags help remove the need for post-use washing and reduce cleaning materials waste.

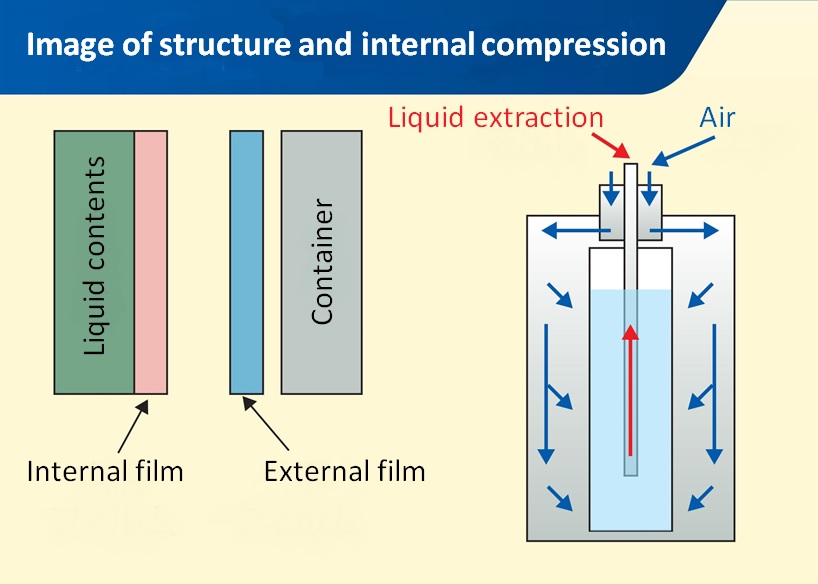

- The dual-layer structure of the combined transport container and chemical carrier bags makes it possible to reduce residual liquid in the container when removing the chemical liquid under pressure.

- The chemical carrier bags use a proprietary DNP-developed inner film that includes components that do not dissolve into the chemicals, reducing the impact on the transported chemicals.

- The outer film utilizes a transparent vapor deposition film with highly developed barrier properties that protect the contents as well as preventing odor transfer.

- The newly marketed chemical carrier bags are capable of accommodating loads of 20 liters-1,000 liters in combination with a variety of transportation containers.

[Looking Ahead]

DNP will propose the chemical carrier bags to various companies, aiming for sales of approximately 1.5 billion yen annually by 2021.

* Product prices, specifications and service contents mentioned in this news release are current as of the date of publication. They may be changed at any time without notice.

- Select location

-

- Category

-