DNP Develops Optimal Curved Resin Glass for EV

Dai Nippon Printing Co., Ltd. (DNP) has developed a light weight resin glass with optimal superior bendability for the curved rear windows in automobiles.

In addition to promoting the provision of this new product for use in automobiles, the Company will respond to the lighter weight needs of Electric Vehicles (EV) by aiming for the development of resin glass rear windows integrally molded with functional components, such as roof spoilers and tail lamp covers.

[Development]

In order to respond to the strengthening of CO2 emission regulations and the shift to EV witnessed in countries around the world in recent years, automobile manufacturers have been engaged in reducing the weight of automobile bodies. Amidst such developments, there are increased hopes for plastic resin glass, including polycarbonates, that is lighter than glass, and which maintains superior impact resistance and thermal insulation.

DNP has positioned Lifestyle and Mobility as a business growth area, and is engaged in the expansion of automobile-related business that capitalizes on strengths in printing technology. As part of these endeavors, in February 2016, the Company transferred a hard coat layer onto resin surfaces, such as polycarbonates, successfully developing a resin glass that improves weather resistance to sunlight and rain, along with wear resistance.

Following this, in January 2017, the transfer film was improved and curve conformability boosted, and a curved resin glass was developed that made it possible to use with curved shapes, such as automobile sun roofs.

In this latest development, the bendability has been further increased, facilitating the use of the new glass in integrated moldings with functional components, such as roof spoilers and tail lamp covers that comprise rich design features.

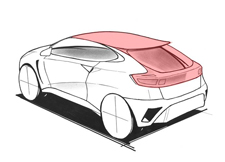

Curved resin glass showing with a 30mm diameter arc in the lower part of the image

[Features of Curved Resin Glass]

- It is possible to achieve bendability up to a minimum of a diameter of 30mm.

- By transferring an ultra-weather resistant hard coat layer to the surface of the resin, it has been possible to boost weather resistance and with wear resistance.

- Via the simultaneous execution of the resin extrusion and hard coat layering, compared to current methods, whereby the hard coat layer is formed using a spray following the bending of glass, it is now possible to simplify the process, making it easy to large-size, while also maintaining superior uniformity of the hard coat layer.

- The weight is approximately half that of standard glass while maintaining similar transparency to glass.

- The newly developed glass maintains high impact-resistance, and is more difficult to break than standard glass, thus feeding into superior safety features.

[Looking Ahead]

DNP will market the curved resin glass for such mobility uses as automobiles, busses and railroad cars. Aiming for sales of 5.0 billion yen in FY 2020.

- Select location

-

- Category

-