DNP Develops New Type of Adhesive Film

Makes it easy to bond objects made from different materials

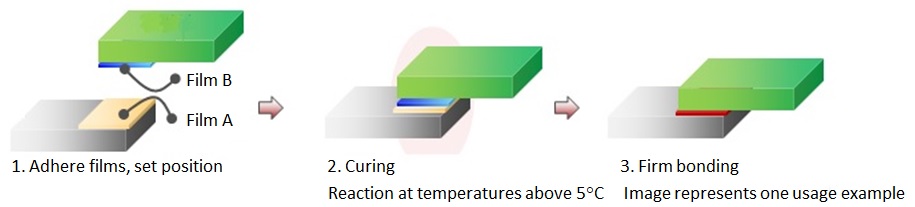

Dai Nippon Printing Co., Ltd. (DNP) has developed an adhesive film capable of adhering objects made of different materials, such as metal and plastic, by producing a curing reaction through the bonding of two kinds of adhesive films.

[Background]

We have recently seen a more pressing need to lower the environmental impact by reducing the weight of automobile chassis, and there are increasing examples of replacing part of the conventional metal materials in autos with those such as plastic or carbon fiber. Methods used to obtain a composite material, in which metal materials and plastic are adjoined, include a method for extrusion molding molten plastic on metal materials, and for bonding a metal and a plastic material using adhesive or an adhesive film. The liquid adhesive used in this case, which combines two liquids, presents the challenge of needing to mix the two liquids in a precise balance, and that the liquid drips or sticks out before the reaction is completed. In addition, when using an adhesive film there are cases of the deformation or shrinkage of film with the passage of time, otherwise referred to as low creep resistance, and / or of function impairment due to heat, also known as low heat resistance.

To address these issues, DNP has developed an adhesive film that produces a curing reaction by bonding two adhesive films, and that exhibits an adhesive strength of practical use when placed at room temperature for approximately one day following execution.

[Product Features]

- The newly developed product produces a curing reaction by joining together two adhesive films coated with different elements, then following the bonding of the different materials, exhibits practical adhesive strength when placed at room temperature for approximately one day.

- Since it is not a liquid, there is no dripping or sticking out of liquid, which can be seen when using liquid adhesive.

- Each of the two adhesive films is coated with an appropriate amount of the necessary elements, so that it is possible to achieve the optimum combination merely by performing bonding. It is possible to prevent errors that can happen in controlling the ratio of liquid adhesives and compounding them.

- As the new product comes in tape form, it is easy to reduce instances of displaced components, and work efficiency is improved.

- It is possible to firmly bond different materials such as plastic, carbon fiber and metals.

- Exhibits heat resistance and creep resistance, or less change with time, shear resistance, or a strong adhesive strength over the adhesive surface, making it possible to use as a structural adhesive that requires strength and durability.

- Both of the newly developed adhesive films can be stored for a long period of 6 months at 23 C.

[Looking Ahead]

DNP will market the newly developed product for mobility, building and electronic components, where there is a strong need to bond different materials, such as plastics, carbon fiber, fiber, and metal, aiming for sales of 1.0 billion yen per annum in 2025.