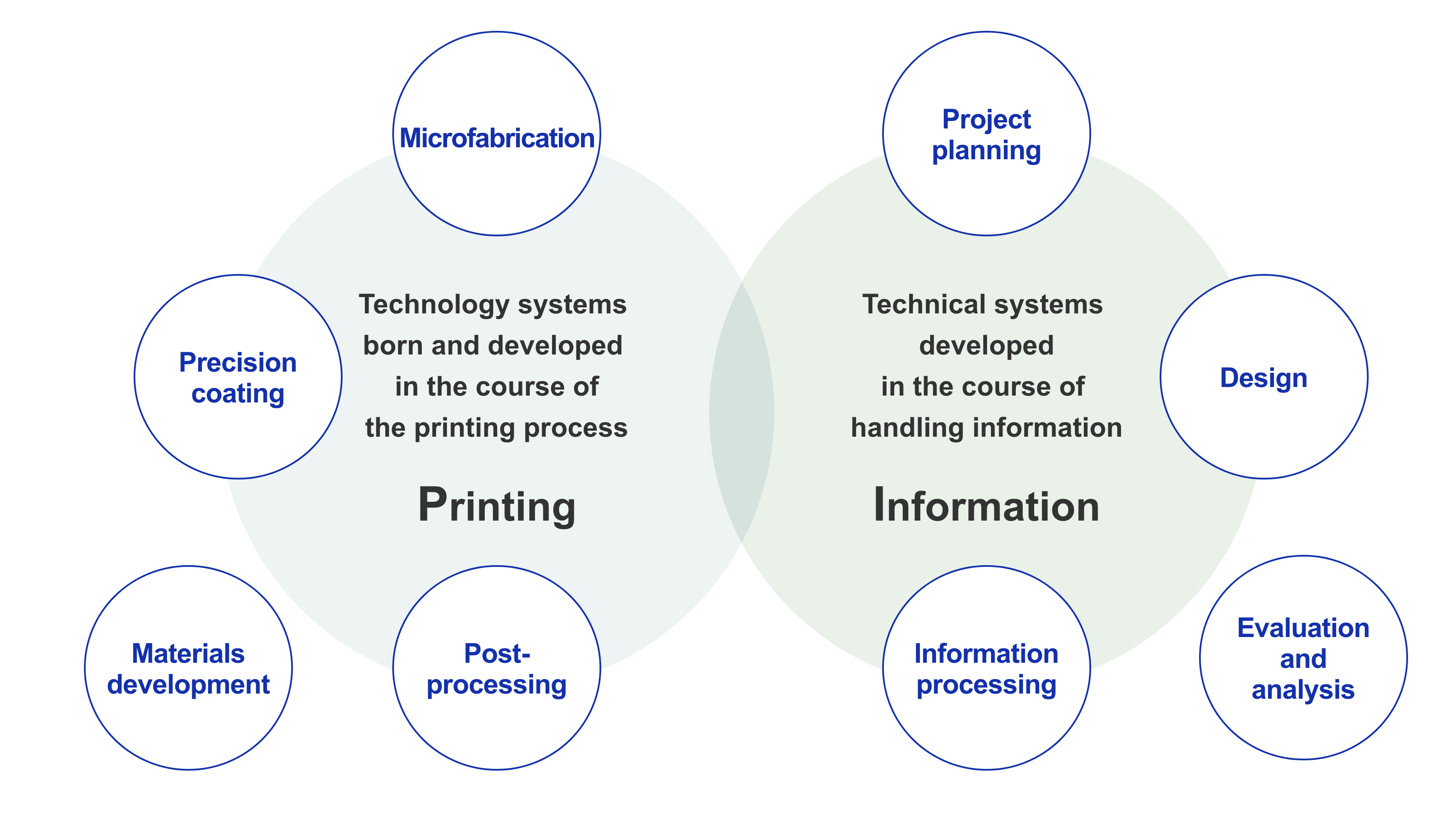

DNP's Basic Technologies

Since our founding, DNP has possessed a wide range of technologies cultivated through the development and continued provision of products and services that exceed society's needs. DNP's basic technologies are developed by adding the latest technologies to DNP's proprietary technologies born from the printing process, and by upgrading and synergizing each of these technologies.

Information technology

Project planning

Technology to promote projects through dialogue, by first considering what we are creating and why

Publishing solutions

Suitable materials can be selected from any type of media, including paper, electronics or the web, and it is possible to propose and respond with effective methods of expression, including still images, video, CG and AR/VR. Composite cross-media solutions are also feasible, such as taking two dimensional characters and deploying them in real world situations, such as fan events. We also offer back-end support, such as copyright management and sales through affiliated store outlets.

Branding design

We identify the strengths and weaknesses of client operations through surveys of products and companies, and targets are set accordingly. Branding solutions include formulating identities and philosophies, drawing up marketing strategies, proposing brand names and designing logos. Our experience working with over 30,000 companies is also a distinct competitive advantage.

Sales promotion

We provide total design and execution, from marketing research to the production, delivery and analysis of different promotional tools. Clients select the scope of their initiative, from personal advertising to mass marketing.

Design

Technology for robust and precise designs for realization

Packaging design

We conduct R&D, planning, design and application development with the aim of creating packaging that is friendly to users, the environment, and of course, the product itself. Our manufacturing expertise allows us to realize universal design, for which functional balance is key.

Living space design

DNP has a long history of producing interior and exterior materials for buildings including homes, offices and medical clinics, as well as for automobiles and railcars. Drawing from that experience, a wide range of products and services are available for making living spaces more comfortable. Information technology can also be integrated to create new types of spaces that are convenient and pleasant.

Optical design

Product functionality is emphasized through optical technology that controls the color and direction of light. At the micro- and even nanometer level, the product's surface or layered structure is strictly regulated, including measurement errors in the manufacturing process. These technologies are used to realize the functionality of electronic goods, energy-related products and decorative elements.

Information processing

This technology safely collects, organizes, analyzes and processes information to create new added value, as well as new ways to employ this value

Information processing: Origins and development

Information security technology

With vast experience in handling highly confidential printed documents, such as bank books, ATM cards and stock and bond certificates, DNP has developed technologies for authenticating personal identity and encrypting data for secure transmission. By integrating software with hardware – as seen in smart card readers and writers – highly safe and secure transactions are possible.

Big data analysis technology

Big data analysis technology can extract, sort and process information according to fixed parameters, including consumer usage trends for information services, purchasing records and climate change data. Set patterns are identified from the processed information to make forecasts or suggest improvements.

Image processing and recognition technology

A refining technology that applies appropriate processing to still and video images. This technology also reads target images and recognizes people and scenery. It can be used for identifying people, in photography applications and for other purposes.

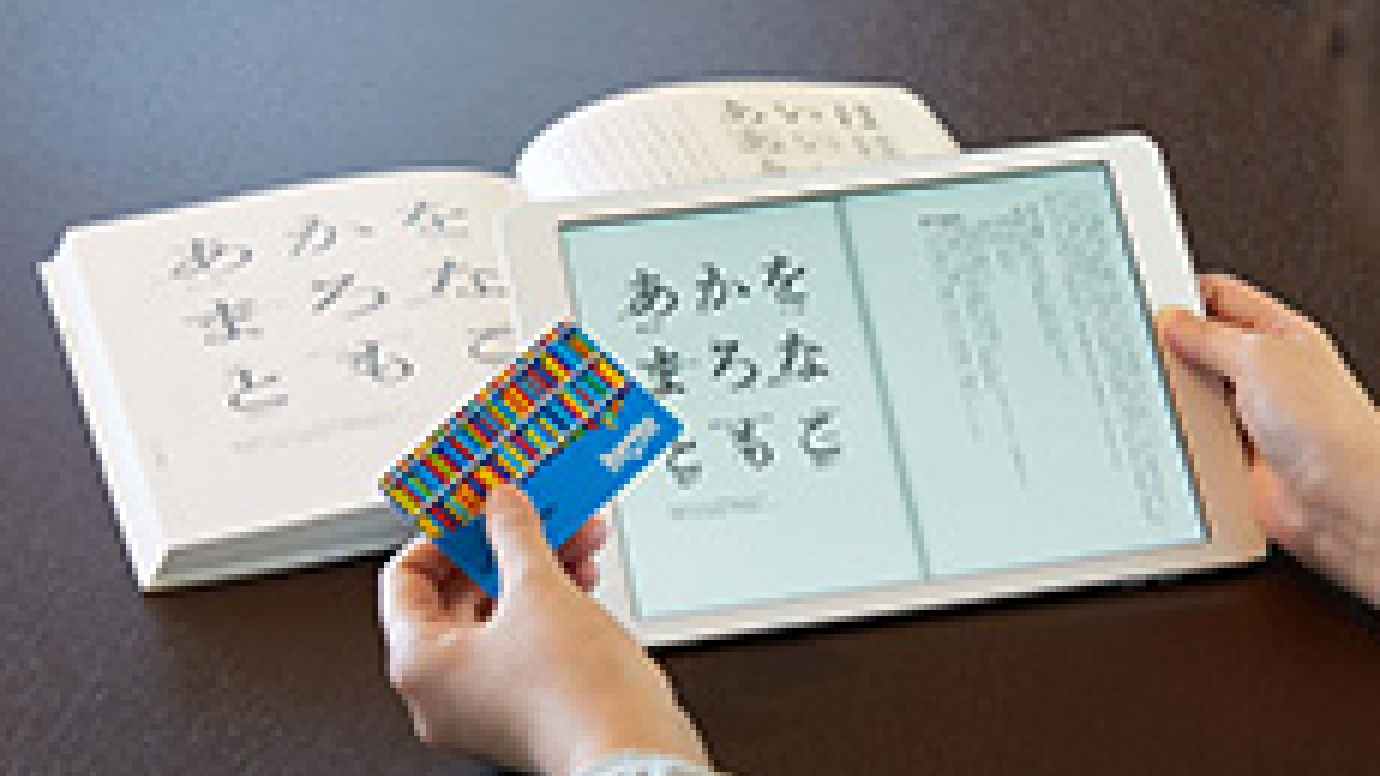

Media conversion technology

A technology for converting information data such as text and video images into various formats to match a variety of media, including paper, e-books, the internet and DVDs, along with communications.

Font technologies

DNP's original typeface, Shueitai, has been in use since Japan's Meiji era (1868–1912). Our typeface technology has adapted to shifts in media across the generations, from metal printing blocks to computer phototypesetting and later, digital. To remain compatible with the digital age, modifications were made to 120,000 typesetting characters beginning in 2005 – an effort that took seven years.

Printing technology

Microfabrication

Technology to process base materials such as metals, glass and resins with high precision and accuracy, and to give them the effects and functions necessary to achieve a desired goal.

Microfabrication: Origin and development

Photolithography technology

A technique to duplicate images onto the surface of a substrate coated with photosensitive material by exposing original images using shining light or electron beams. This technology is used in the printing process to produce printing plates from photographic film originals of images and lettering, and has been applied in industries that demand precision, such as electronics.

Precision engraving technology

An engraved cylinder used in photogravure printing is configured as an aggregate of individual concave cells of the text and pattern, which are engraved by varying their size and depth. These engravings range from those manually carved by a craftsman to those made using micro-order and nano-order precision cutting equipment. The appropriate technology is employed in line with the desired objective.

Molding technology

Molding technology is applied to printing substrates to replicate uneven shapes, such as the text or geometrical patterns formed in the metal, glass or resin molds originally used. It was developed from an embossing process performed to align printing patterns and from the machining of lenticular lenses used for 3D printing.

Etching processing technology

A technology for processing desired structures by chemically corroding and removing materials. This technology has evolved from the printing process, including resin letterpress and photogravure plate manufacturing technology. When used in combination with photo-engraving technology, it is possible to produce fine and high quality plates.

Hologram technology

We have conducted R&D on techniques for recording and printing 3D images. We use two methods in this area: one to record the intensity and phase of laser reflected light from a real model directly onto a photosensitive material using the interferometric property of laser light, and another to record computer-calculated optical interference fringe data directly by electron beam lithography.

Precision coating

Technology to form homogeneous and uniform coating films from various materials in single or multiple layers on the surface of base materials such as paper, resin, metal and glass.

Precision coating: Origins and development

Printing technology

This is a general term for a process that applies ink to a printing plate prepared from manuscripts, including text and images, and transfers the ink to a substrate such as paper, facilitating the high-speed, high-volume reproduction of manuscripts. Toner-based printing and ink jet printing developed in recent years do not require a printing plate, and by controlling the ink transfer volume, it is possible to print directly from digital manuscript data.

Vacuum film deposition (dry coating) technology

A technology for coating a super-thin film onto substrate such as plastic film by applying evaporated substances in a vacuum. This technology has made it possible to manufacture the high-precision glass / thin metal master plates required in the semiconductor manufacturing field.

Coating technology

A process for applying ink in a thin, uniform fashion to the surface of the material substrate, including wet coating – where coating resins or materials such as ink are applied as a coat – and dry coating, including metal deposition. By combining this technology with design technology for the base material, it is possible to configure coatings with different functionality, including optical properties, barriers and heat-resistant features.

EB and UV curing technology

A technology that instantly cures resin and coating film materials by exposing them to electron beam (EB) or ultraviolet light (UV). This technology has evolved to significantly shorten coating resin and ink drying time in the printing process. It allows for energy savings in the production process, CO2 reductions, solvent-free coating and the facilitation of clean coating processes with a low environmental burden.

Post-processing

Technology to achieve safety, durability and convenience required for the environment in which products are used for their intended purpose

Post-processing: Origin and development

Bookbinding technology

Bookbinding is the process of arranging printed pages into book form. Various methods are used for each of the basic steps of folding, binding and trimming the paper, including processes for making pop-up and double-leaved books.

Transfer processing technology

Instead of pressing ink directly to a substrate, printing elements are applied to a carrier film, and then pressed onto the substrate with heat. The substrate can be plastic, glass, metal or other material.

Transfer processing is widely used for decorative films, and also for designing containers and interior components for vehicles.

Laminating technology

This technology is used for evenly laminating materials like film, metal and resin. It provides high performance for multiple functionalities, including as a water vapor barrier, or in terms of durability.

Plastic molding and forming technology

This technology is used to form resin products into 3D objects, beginning with plastic containers. It can be applied to products of all sizes, from small liquid container spouts to large automobile components.

Aseptic filling technology

This is a process for filling containers with food or liquids under aseptic conditions. The delicate flavors of food and beverages can be preserved and protected from the negative effects of heat pasteurization before shipping. The technology also reduces logistics costs, as the bottles are created from a test-tube sized preforms immediately prior to filling.

Materials development, evaluation and analysis

Materials development

Technology to synthesize, disperse and mix new materials, and to design and produce inks, adhesives, photosensitive materials, coating materials, etc.

Pigments and photosensitive materials

These materials are used for producing colors, and setting shadows and images created by light. An ultra high-quality mixing technique is used for photolithography, which requires precision at the micron level. DNP independently develops and manufactures many different pigments and photosensitive materials.

Polymeric materials

Along with inorganic materials like metal and ceramics, polymers play an important role in everyday life, and are mainly used for plastics and resins. They are the main components of food packages and interior decorative materials. In combination with converting technology, they are used in specific applications, including base material films and optical resins.

Organic synthesis technology

A technology for synthesizing organic materials and making them suitable for various products. DNP produces functional materials, e.g. coating materials, photoresists for advanced photomask fabrication, and active pharmaceutical ingredients.

Dispersion and mixing technologies

The functional capacity of materials is determined through these technologies. For materials to function at a high level, the best combination of raw material ingredients is determined and uniformly dispersed to ensure consistent quality.

Evaluation and analysis

This technology is indispensable for product assurance relating to electronics components that require nano-level precision, and for defect correction to increase yields.

Analysis planning

Designing the assembly of evaluation methods, analytical devices and processing systems. The key is how rapidly and how accurately results can be obtained.

Analysis technology

Physical and chemical analysis methods identify and quantify ingredients, and perform structural analysis through the use of spectroscopy and structural analysis-based cutting-edge analytical equipment. DNP is active in this area through its large scale analytical center.

Simulation technology

Databases are compiled and analyzed according to the purpose of materials manufactured on production lines, airflow behavior patterns and more. This allows for prediction of production line output, alongside quality and performance of materials and products. Simulation technology leads to optimal high-quality material design and efficient and reliable production lines.

Database analysis technology

This technology quickly and accurately identifies the cause of product defects, mainly by comparing instrument analysis data with the proprietary company databases.