Unique “Green Aseptic” Technology Reduces CO₂ Emissions by 40% in PET Bottle Beverage Production

As carbon neutrality spreads worldwide to curb global warming, the beverage industry is accelerating efforts to reduce greenhouse gas emissions (hereafter referred to as CO₂) across the entire supply chain. DNP has incorporated various mechanisms to reduce environmental impact in the development of its aseptic filling systems for PET (plastic) bottles and currently holds the top domestic market share.*1 In spring 2024, this initiative took a leap forward with the successful development of a unique “non-heat sterilization system” that cuts CO₂ emissions by approximately 40% compared to conventional methods in the production of beverages with high water content. Here we introduce the features and future prospects of this sterilization system named “Green Aseptic.”

- Paradigm Shift Yielding a “Non-Heat” Option

- Two-Step Non-Heat Sterilization of Water Using UV Sterilization and Filtration Sterilization

- Reducing CO₂ Emissions from Entire Beverage Production Lines by About 40%

- Becoming the Beverage Industry Standard through Innovation and Global Expansion

- *1 Approximately half of PET bottle beverages produced in Japan use DNP’s aseptic filling systems (as of April 2025, DNP research).

Paradigm Shift Yielding a “Non-Heat” Option

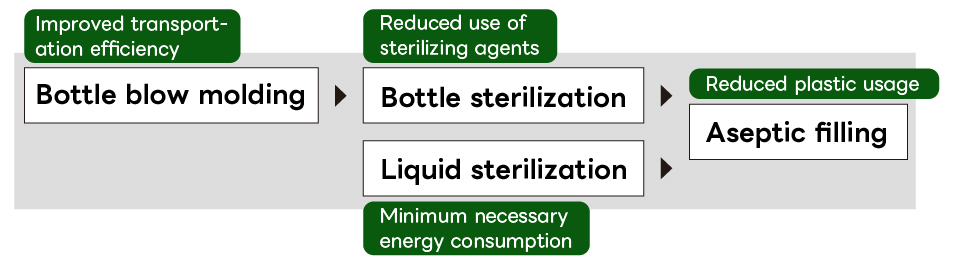

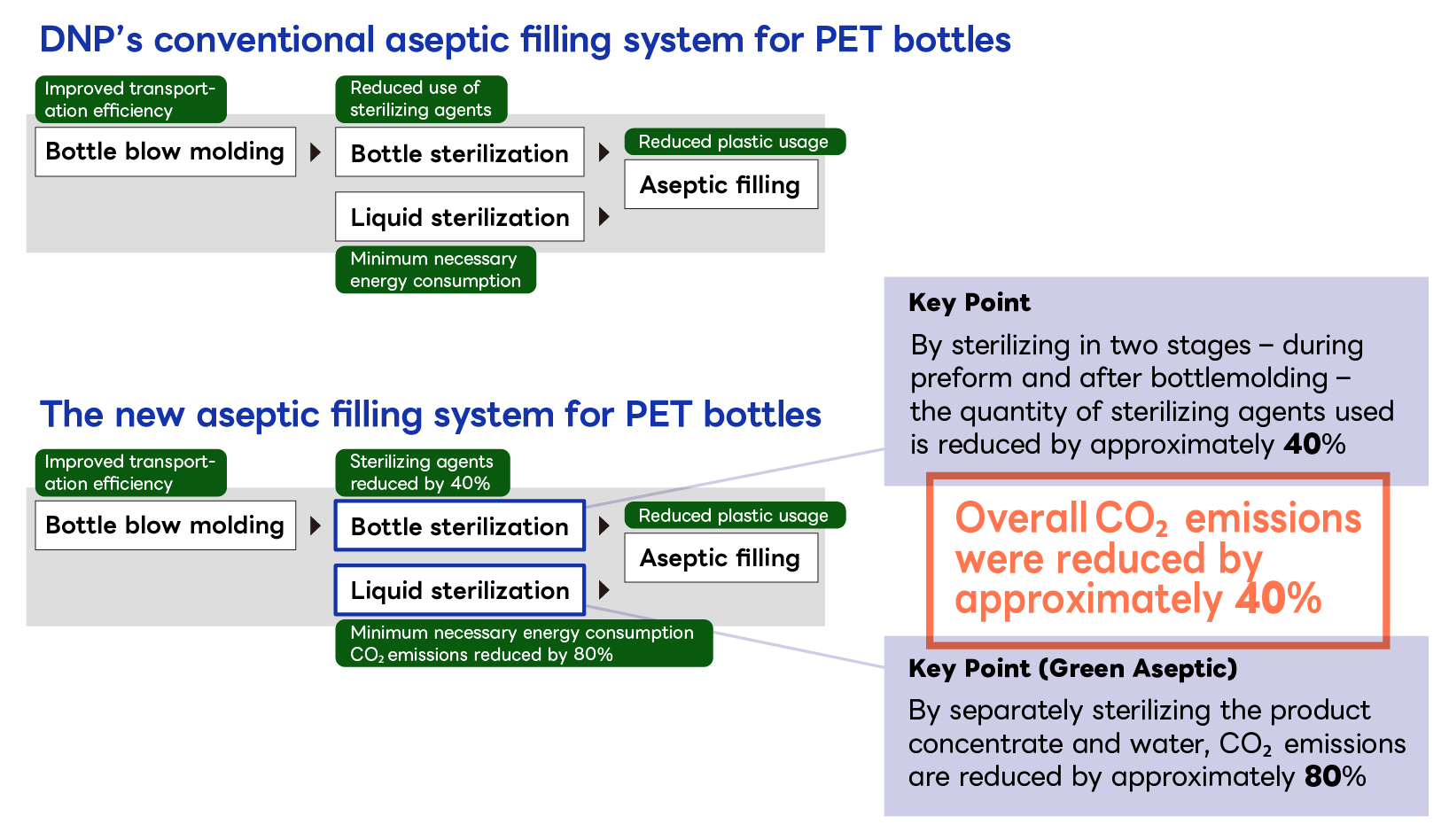

Aseptic Systems Co., Ltd. (APS), a member of the DNP Group, is responsible for developing, selling and servicing aseptic filling systems for PET bottles, and has long led the industry by developing innovative methods to reduce energy consumption and CO₂ emissions. These include improving transportation efficiency and reducing environmental impact by shipping small test tube-shaped preforms to the filling plants where they are blown into bottles; sterilizing beverages with the minimum necessary energy consumption through ultra-high temperature, short-time (UHT) processing; and filling bottles at room temperature which enables lightweight PET bottles to be used, helping to reduce plastic usage.

Each step in the beverage production process achieves both high productivity and environmental performance. APS began developing the Green Aseptic system in 2021. The company started working on further contributions to carbon neutrality by leveraging its own technology, as the Japanese government declared a goal for carbon neutrality and beverage manufacturers accelerated their environmental efforts.

|

DNP’s Conventional Aseptic Filling System for PET Bottles

|

From the early stages of development, APS focused on the “liquid processing stage” – the most energy-intensive process in beverage manufacturing.

Traditionally, aseptic filling systems dilute liquid concentrates such as tea extracts or syrup with water and sterilize the entire diluted mixture by heating it to ultra-high temperature (UHT), then cooling before filling. This step is essential to preserve flavor, aroma and safety, but consumes large amounts of energy and generates significant CO₂ emissions due to heating the entire mix.

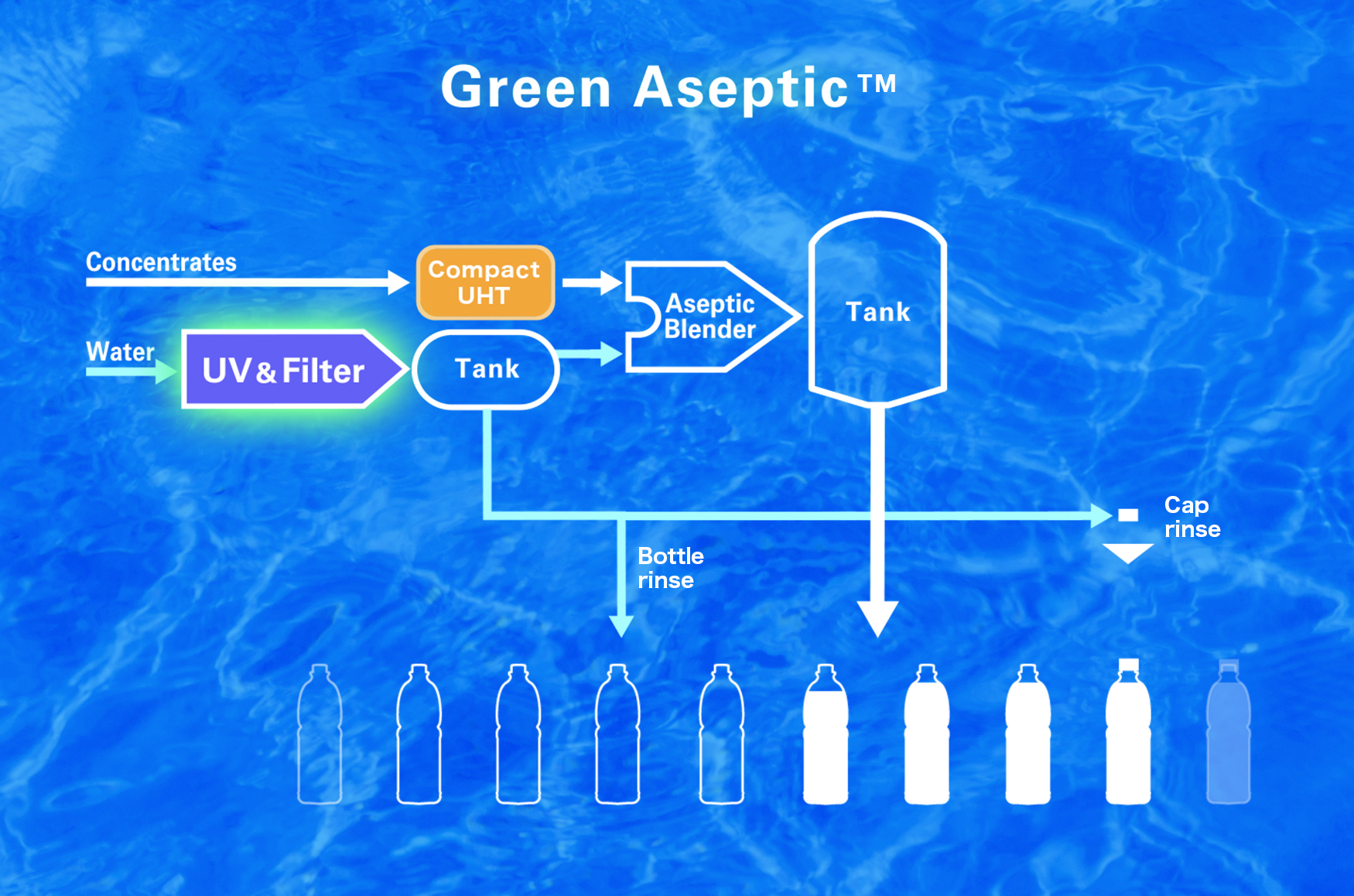

APS focused on water, the primary ingredient of soft drinks. Since water used in beverage factories is already very pure, they considered the possibility of sterilizing the water without heating. If water could be sterilized without heating, APS believed that it would be possible to minimize the amount of liquid requiring heat sterilization to the product concentrate only, significantly reducing energy consumption.

Two-Step Non-Heat Sterilization of Water Using UV Sterilization and Filtration Sterilization

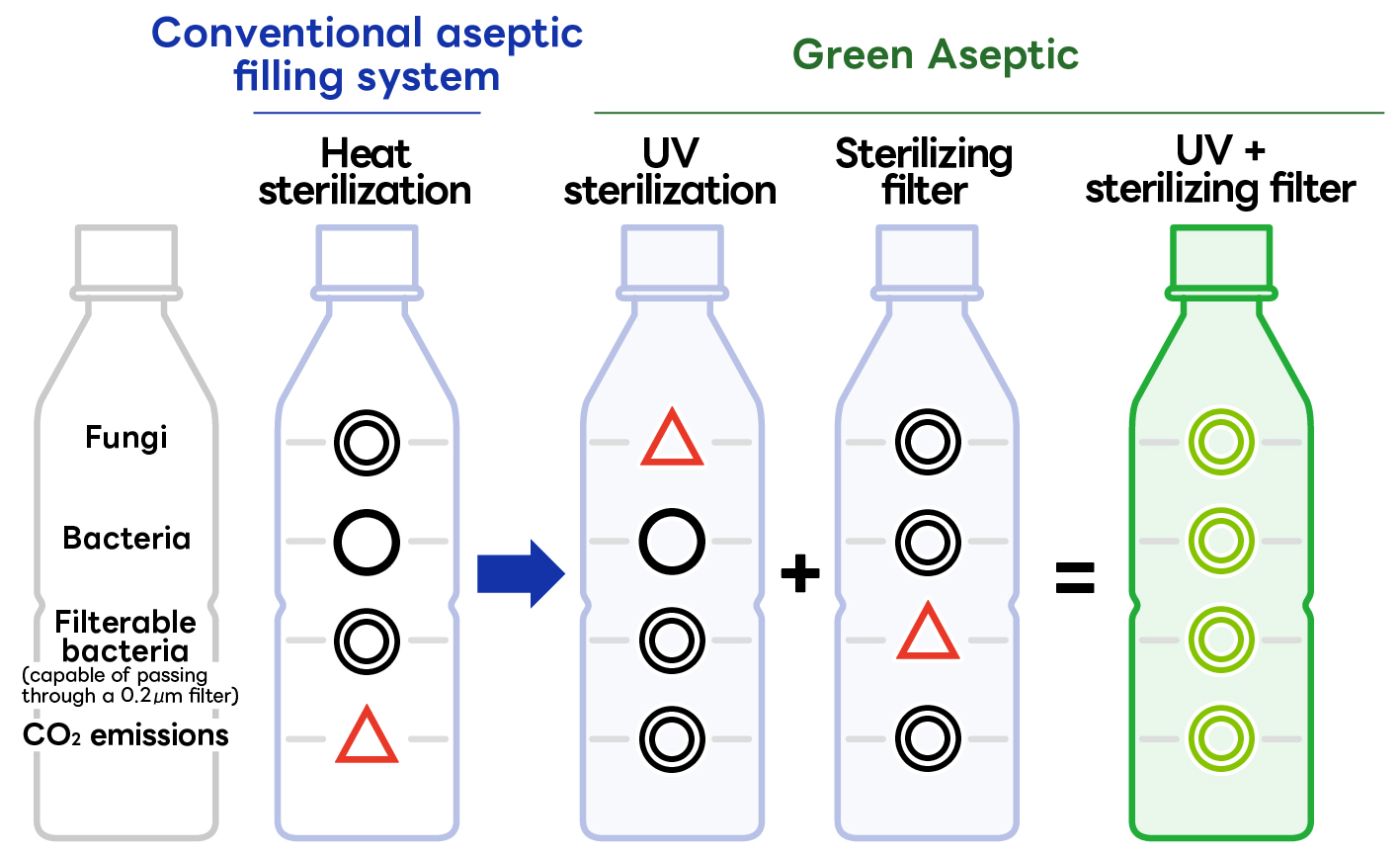

Non-heat sterilization of water involves two main methods: UV sterilization using ultraviolet lamps, and filtration sterilization. However, UV sterilization alone has limited effectiveness against some fungi, while filtration sterilization can eliminate fungi and bacterial spores but cannot completely remove extremely small filterable bacteria. Each method alone cannot provide the level of sterilization required for beverages.

To overcome this, APS developed the environmentally friendly Green Aseptic technology, which combines UV sterilization and filtration sterilization for non-heat water sterilization.

|

Main Methods of Non-Heat Water Sterilization |

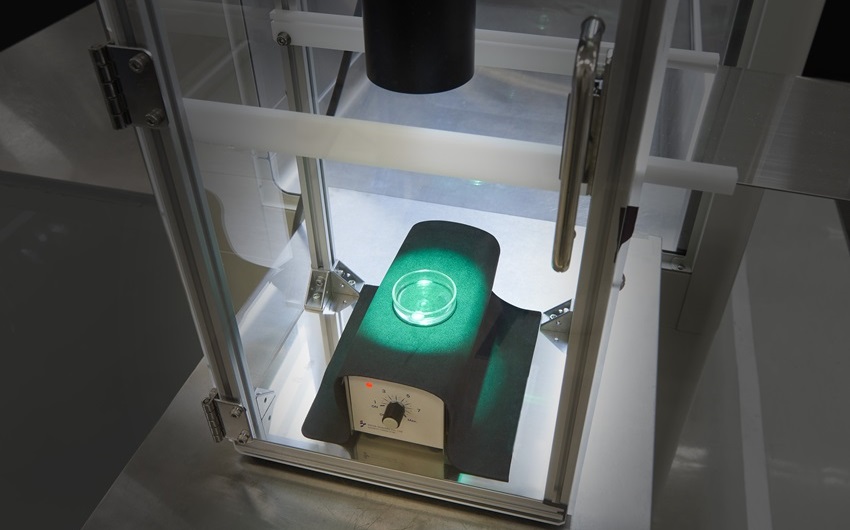

First, water is treated with UV sterilization. The key here is using a “medium-pressure UV lamp” that emits a broader wavelength spectrum at high power, instead of the commonly used “low-pressure UV lamp” for sterilization. UV sterilization devices using medium-pressure UV lamps were not widely available in Japan, but APS modified equipment to incorporate them into their system.

Based on domestic and international studies, they examined target bacteria and collected over 20 strains of typical, filterable bacteria to verify sterilization. They confirmed over 99.9999% sterilization effectiveness against all tested bacteria.

|

Equipment to examine sterilization effects of a medium-pressure UV lamp |

Next, the UV-treated water passes through a sterilizing filter, physically removing any microorganisms or debris that may have survived UV sterilization to produce sterile water.

|

Collection and investigation of microbial strains and verification of sterilization effects are ongoing |

This two-stage sterilization process – UV sterilization plus filtration – achieves a sterility assurance level equal to or higher than that used in pharmaceutical manufacturing, ensuring beverage safety.

Finally, the sterile water produced is blended aseptically with the heated sterile product concentrate in a separate process and filled. This system reduces energy consumption compared to conventional beverage production and cuts overall CO₂ emissions from the manufacturing line. It also potentially reduces running costs by several hundred thousand dollars annually.

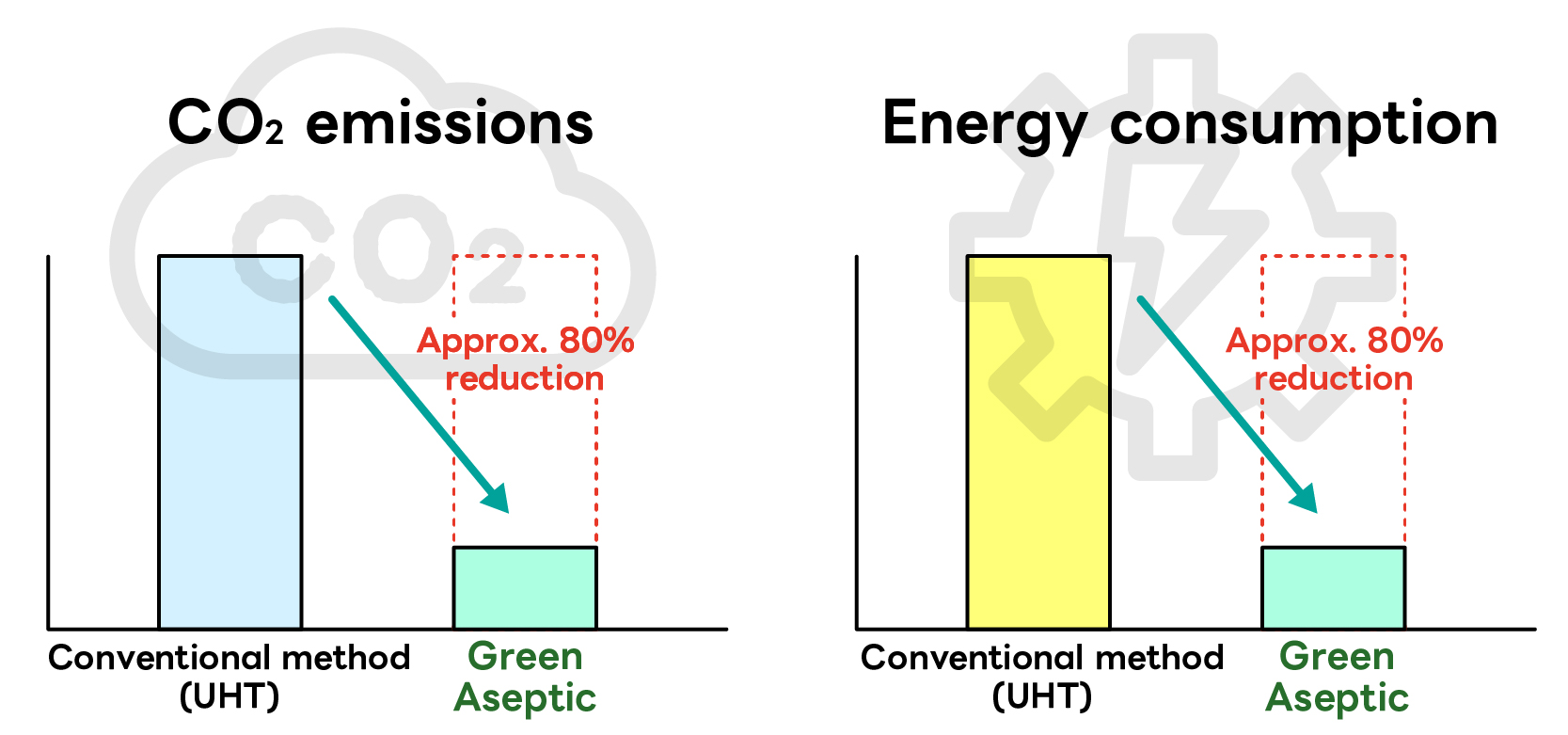

Reducing CO₂ Emissions from Entire Beverage Production Lines by About 40%

The first filling system equipped with Green Aseptic began full-scale operation at a major beverage manufacturer in April 2024. The manufacturer’s beverage processing stage achieved approximately 80% CO₂ emissions reduction compared to conventional full-volume heat sterilization.*2 Additionally, sterilized water used for rinsing bottles, caps and aseptic chambers was switched from heat sterilization to non-heat sterilization.

|

CO₂ and Energy Consumption Reduction Rates in Beverage Sterilization Processes |

For container sterilization, a two-step sterilization system is used where preforms are sterilized before being blown into PET bottles, then sterilized again after bottle formation. This drastically reduces the quantity of sterilizing agents needed. Combined, these measures reduce overall CO₂ emissions in beverage production by about 40%.

|

Comparison of Conventional DNP Aseptic PET Bottle Filling System with the New Aseptic Filling System |

Green Aseptic’s proven high energy-saving performance was recognized as an “Advanced Equipment/System” eligible for energy-saving subsidies by the Agency for Natural Resources and Energy*3 of the Ministry of Economy, Trade and Industry. This technology significantly lowers capital investment costs for beverage manufacturers.

- *2 The approximately 80% reduction applies when the dilution ratio is 4:1. Reduction effectiveness varies with dilution ratio.

- *3 Green Aseptic was registered as a subsidized advanced equipment/system under the FY2024 supplementary budget for the subsidy program for “Energy-Saving Investment Promotion & Demand Structure Transformation Support Project” provided by the Sustainable Open Innovation Initiative.

However, manufacturers must carefully consider product impacts when switching processes. Since water and product concentrate are sterilized separately and blended, taste, flavor, aroma and other sensory attributes require thorough evaluation compared to conventional full-volume heat sterilization. APS is therefore strengthening collaboration with beverage manufacturers and support related to equipment installation.

|

Green Aseptic test equipment in DNP’s lab undergoing various tests to maintain prescribed sterility levels. |

Becoming the Beverage Industry Standard through Innovation and Global Expansion

APS is working to further improve the energy savings and safety of Green Aseptic, while also advancing technological improvements and innovations to enable it to accommodate a wider range of beverages.

For example, adjusting UV exposure and filter types according to the sterilization levels required for different drinks such as tea, sports drinks and carbonated beverages with the aim of further reducing costs.

Leveraging its top domestic market share of aseptic filling systems for PET bottles, the DNP Group will continue to develop Green Aseptic into the “industry standard” technology for beverages. The goal is to introduce it to multiple production lines in Japan by 2030, building a recognized and respected track record of operation.

Internationally, collaboration with global beverage manufacturers will accelerate overseas expansion. Especially in Asia, where the tea-based beverage market is rapidly growing and highly compatible with the features of aseptic filling systems, this is seen as a promising market.

In the medium and long term, DNP plans to expand the application of Green Aseptic beyond PET bottle soft drinks to include beverages filled into paper containers and cans, combining it with DNP’s diverse packaging technologies to advance research.

The DNP Group is committed to promoting Green Aseptic, which balances environmental impact reduction with economic efficiency, as the standard aseptic filling system in the beverage industry. As a trusted partner for beverage manufacturers aiming for carbon-neutral factories, DNP will continue to create the “future standards” of a decarbonized society.

|

The spread of systems that reconcile environmental impact reduction and economic efficiency will broaden beverage manufacturers’ development choices and enable consumers to enjoy a wider variety of drinks produced in a sustainable way than ever before. |

-

*Please note that the information contained in this story was accurate as of the publication date.

September 12, 2025 by DNP Features Editorial Department

Discover more

Related products and services

New Environmentally Advanced Aseptic Filling System: Green Aseptic™(Open in a new window)

With the global demand for soft drinks continuing to grow, the use of PET bottles is expec...

DNP's Mono-material Packaging(Open in a new window)

This environmentally friendly package is made from a single material (Mono-material), maki...