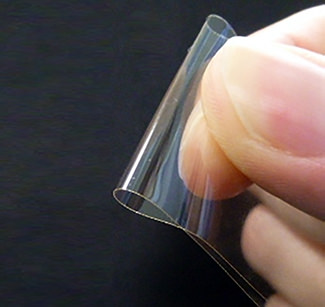

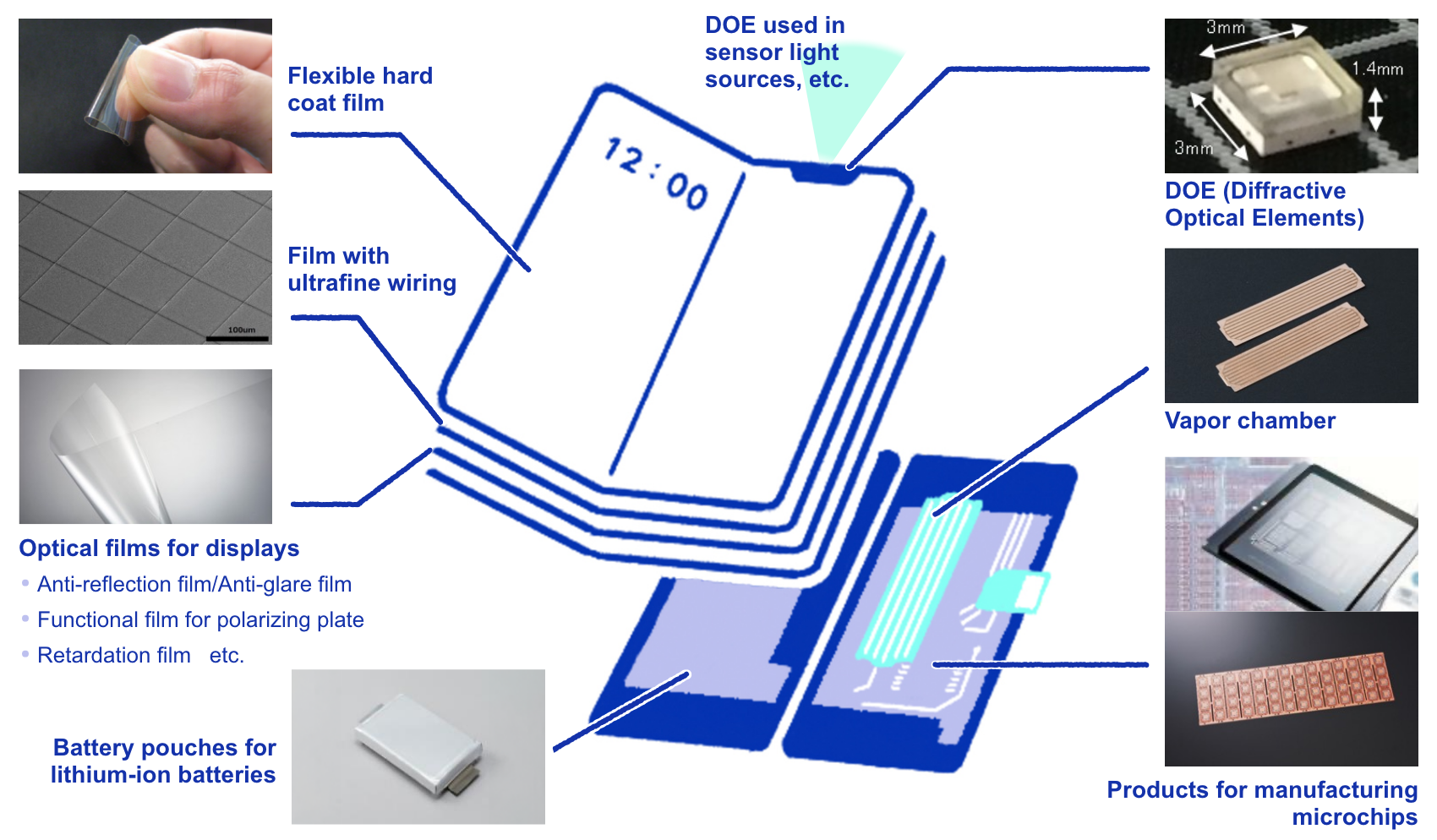

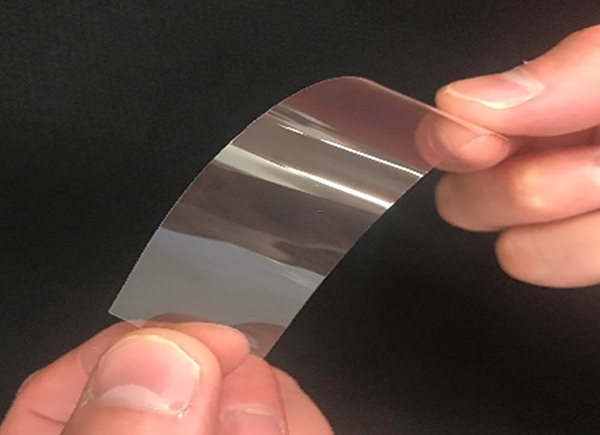

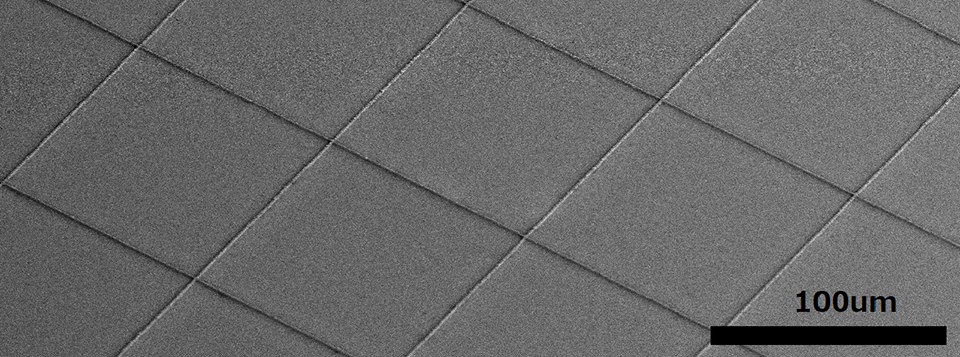

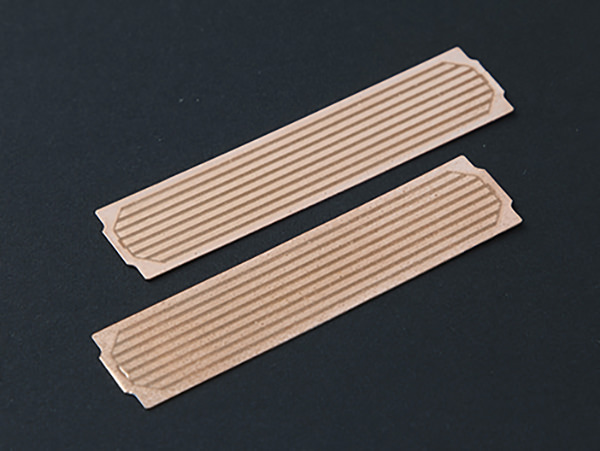

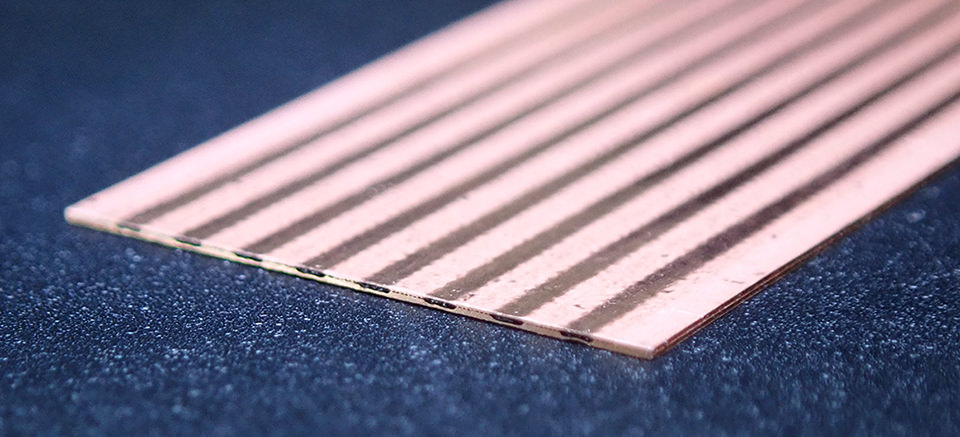

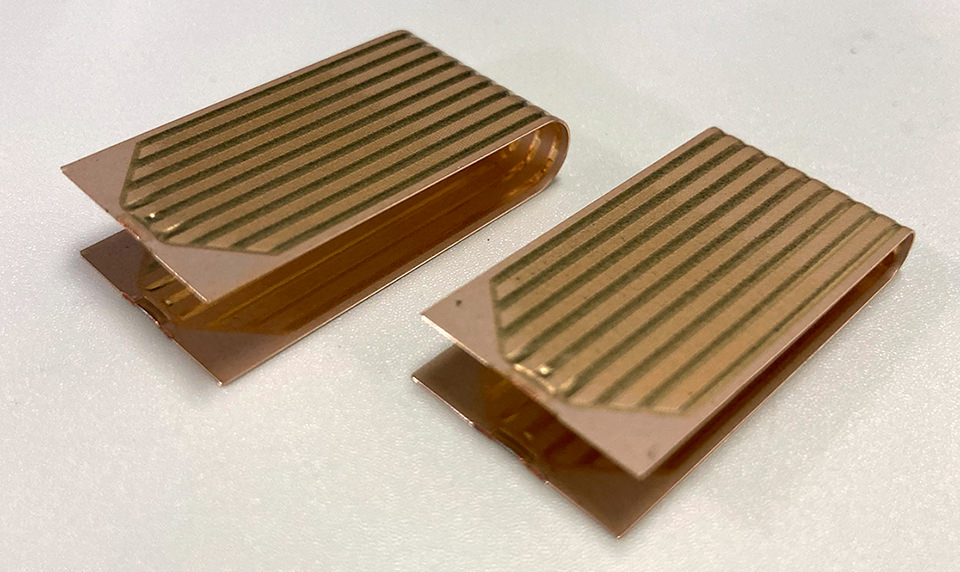

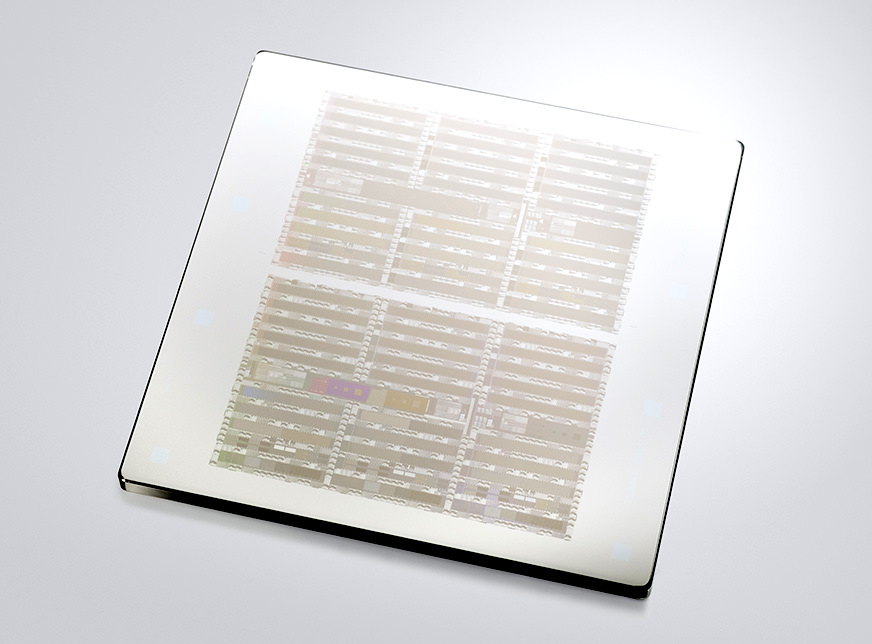

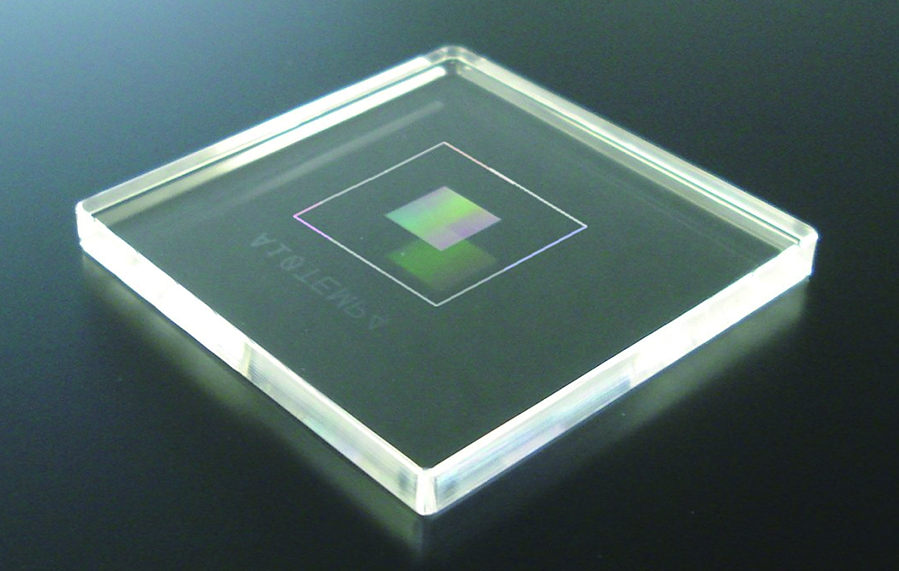

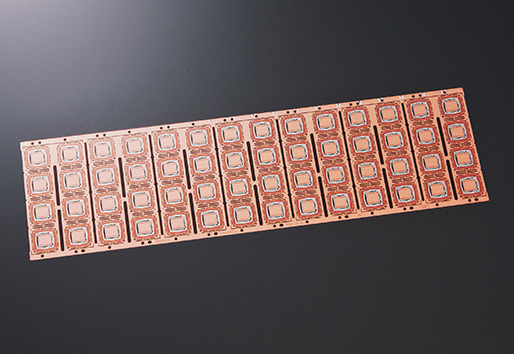

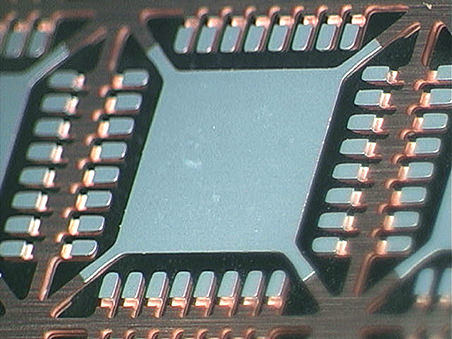

Flexible hard coat film

Essential components for foldable displays

A Flexible hard coat film that is both rigid and flexible. This film not only enhances the visibility and vividness of displays on foldable smartphones but also improves the visual experience on tablets, PCs, and various other devices.

By employing clean converting technology that processes materials in a manufacturing environment with excellent dust resistance, it becomes feasible to incorporate various functions. These functions may include scratch resistance akin to glass, along with antistatic and antifouling properties, depending on the device in use.