Materials for Supporting a Healthy Lifestyle

DNP’s technology developed from the printing process to enhance the quality of people's lives

DNP's technology, derived from the printing process, is integrated into various aspects of daily life. Beyond design, DNP's technologies offer diverse functions, including varied barrier properties in packaging materials, scratch resistance, and weather resistance in products for living spaces like walls and floors. Additionally, they contribute to improved access to 5G radio waves in the telecommunications sector. In the life science field, these technologies are instrumental in enhancing the efficiency of drug discovery.

Functional components with design features

5G film antenna

5G antennas blended into our lives

This antenna, thinner than conventional products, features flexible bending through film-like processing. DNP's expertise lies in diverse surface designs, including wood grain patterns.

DNP combines antenna design technology with etching for fine metal patterns to develop a film-type antennas. The sheet covering the antenna surface has been enhanced with EB (Electron Beam) coating to improve the antenna's weather resistance, scratch resistance, and dirt resistance.

Reflect array for 5G mmWave

Delivering radio waves through special reflection for enhanced connectivity and energy efficiency

Efficiently reflecting radio waves for 5G communication standards, this product allows customization of the direction of incidence, reflection, and spread of reflected waves (beam profile) in the target frequency band. It enables the reflection and delivery of radio waves to locations challenging for base station signals to reach, without requiring additional power supply, thus optimizing energy utilization.

Design and simulation technologies, developed for optical films* (for which we hold the world's top market share) and smart cards, are applied to control light, electromagnetic waves, etc. Patterning technology is utilized in processing components to realize functions as designed. For the thin cover layer required for social packaging, we use design sheets for interior and exterior applications, ensuring enhanced durability through EB (Electron Beam) coating technology.

- In the case of anti-reflection film and anti-glare film used on the surface of displays.

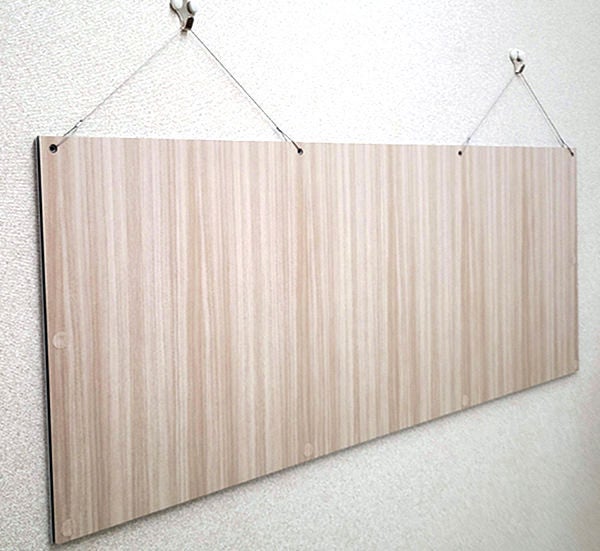

Aluminum decor panel for interior and exterior

Harmonizing sophisticated design and functionality! Bespoke products for interior/exterior

This decorative panel, designed for both interior and exterior use, features wood grain, geometric patterns, etc., directly printed on aluminum. Beyond its impressive design quality, this high-value product addresses the vulnerabilities of natural materials, offering solutions for fire resistance, weather resistance, weight, and ease of processing and installation. It finds versatile applications across various building settings.

Leveraging high-definition data creation and plate-making technologies honed in the printing process, along with precision coating technologies, this product allows the expression of the allure of natural materials like wood, stone, and metal. DNP's distinctive materials, utilizing the qualities of aluminum as a base, contribute to crafting comfortable and functional spaces.

High barrier materials

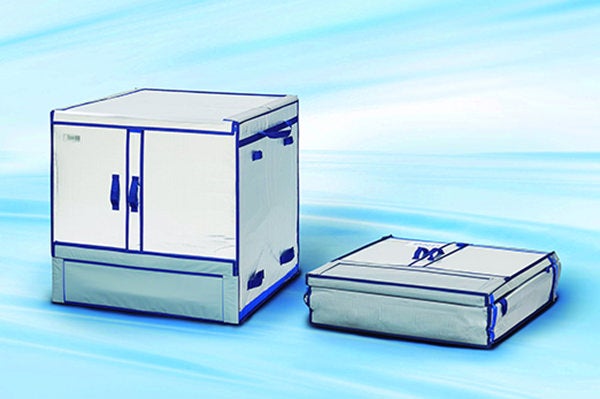

Multifunctional insulation box

Maintains a consistent temperature over an extended period without requiring power

Sustains a consistent internal temperature over extended durations without relying on electricity. This innovation plays a crucial role in addressing logistics challenges related to perishable foods, industrial products, and pharmaceuticals requiring precise temperature control. Furthermore, it significantly lessens the environmental impact by enhancing efficiency through the combined transportation of room temperature and refrigerated/frozen products, while also minimizing the use of disposable materials through a focus on reuse.

Utilizing "vacuum insulation panels" incorporating advanced high-barrier technology with low gas permeability that restricts the passage of oxygen, water vapor, etc., along with thermal design technology based on comprehensive simulations, and material development expertise.

Corrosion inhibition film

Ensures long-term protection of contents from corrosion, including rust and other forms of deterioration

This film hinders the permeation of oxygen and water vapor, safeguarding contents from rust during extended transportation and storage periods. Not only is the film transparent, facilitating easy content checks, but it is also highly effective in preventing rust. The manufacturing process doesn't require cleaning since it doesn't use vaporizable rust inhibitors or rust-preventive oils. Combining it with DNP's eco-friendly, plant-based packaging materials further enhances functionality.

The product seamlessly integrates lamination technology, which combines multiple materials, and high-barrier technology, preventing gas permeation. DNP's transparent vapor deposition film is laminated onto the sealant film and protective layer film, heat and pressure bonded together. This transparent vapor deposition film has been a staple for decades in various fields such as electronics, medical, and healthcare.

Mono-material packaging

Achieving high recyclability

Crafted from a single material (mono-material), this packaging is easy to recycle. We are proactively introducing this solution in both domestic and international markets, contributing to the realization of a circular society.

Converting technology and film deposition technology to process materials with diverse functions, and vapor deposition technology for high barrier are the key-solutions. By synergizing these technologies, we embed essential functions into packaging for a "better future."

Healthcare and life science

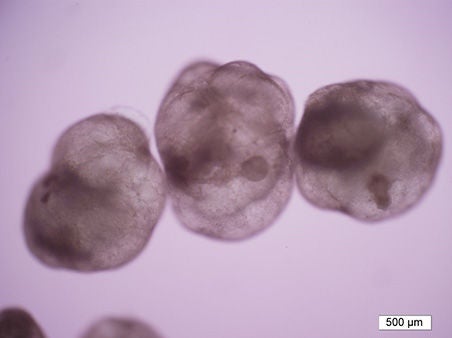

Intestinal organoids "mini-guts"

Artificial organs for facilitating drug discovery support

Despite its diminutive size (1.5 mm in diameter), this three-dimensional miniature organ emulates the functions of a human intestine, encompassing absorption and peristalsis. Beyond its anticipated role in pharmaceutical development, its potential is expanding to include experiments assessing the absorption effects of foods for specified health uses and functional foods, among other possibilities.

We will employ thin-film multilayer patterning technology, a fusion of DNP's microfabrication technology and precision coating technology, to develop and provide patterned base materials for cultivating cells to form intestine organoids.

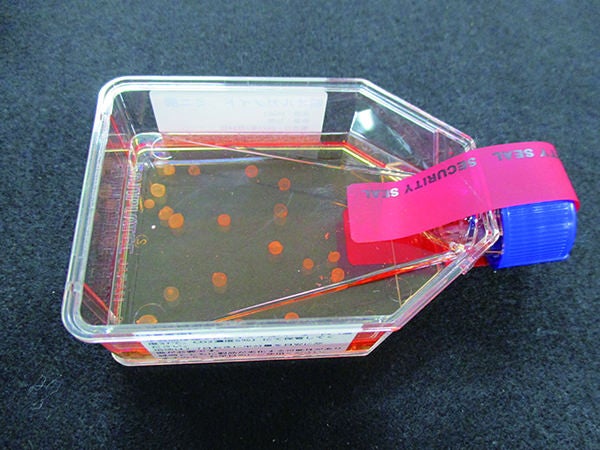

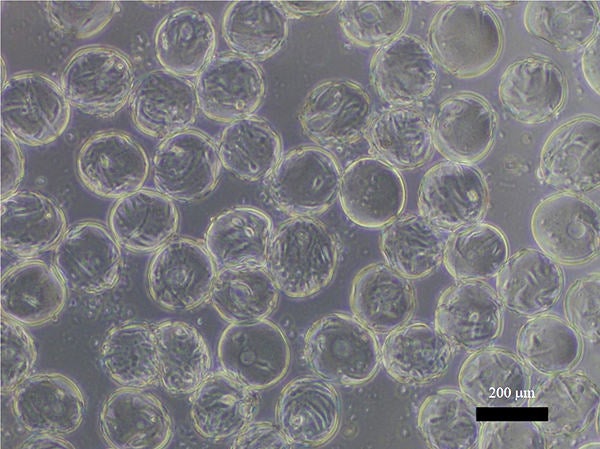

Soluble microcarriers

Boosting efficiency through three-dimensional cell culturing

Provided by: Kinooka Laboratory, Graduate School of Engineering, Osaka University

Provided by: Kinooka Laboratory, Graduate School of Engineering, Osaka University

Microcarriers, microscopic particles that anchor cells to their surfaces in culture medium, facilitate three-dimensional cell cultivation. Unlike conventional two-dimensional culture using petri dishes, microcarriers save space, enabling large-scale cultivation, thereby enhancing work efficiency and reducing costs.

DNP's proficiency in surface processing technology and material selection has also been extended to micro particles. Collaborating with partner companies specializing in cell culture technology further accelerates our development process.

Other featured articles

DNP’s core technologies cultivated from the printing process

Since our founding, DNP has developed its core technologies by incorporating the latest advancements into its proprietary technologies derived from the printing process, and by upgrading and synergizing each of these technologies.

Please feel free to contact us at any time. We are here to answer any questions you may have.